Sludge drying and carbonizing processing device

A carbonization and drying technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Low cost, less auxiliary fuel, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

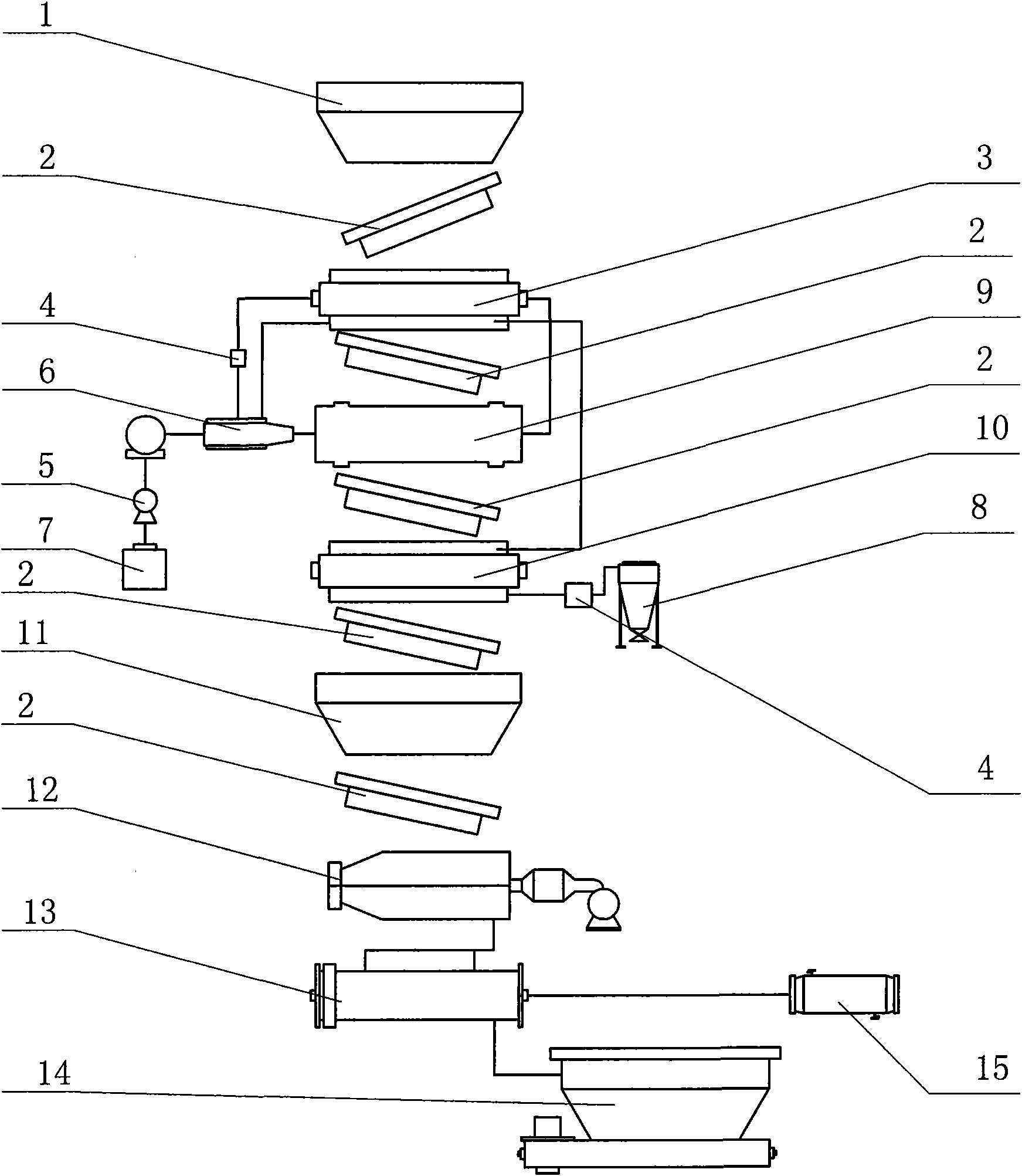

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] As shown in the accompanying drawings, the sludge drying and carbonization treatment device includes a drying treatment device and a carbonization treatment device. 4. Composed of pump 5, combustion furnace 6, fuel tank 7, cooling tower 8, rotary kiln 9, secondary dryer 10 and dry matter storage tank 11, the sludge stored in the hopper 1 enters from the outlet through the screw conveyor 2 The first drying is carried out in the first stage dryer 3, and the sludge after the first drying enters the rotary kiln 9 through the screw conveyor 2, and the sludge is reheated in the combustion furnace again, and then returned to the first stage dryer 3, indirect heating is carried out to achieve the purpose of making full use of waste heat resources. The sludge heated by the rotary kiln 9 is fed into the secondary dryer 10 through the screw conveyor 2 for secondary drying, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com