Energy-saving biomass hot air furnace

A technology of hot blast stove and biomass, which is applied in the direction of fluid heater, lighting and heating equipment, etc. It can solve the problems of low utilization rate of hot blast and low cracking efficiency of biomass cracking furnace, and achieve the effect of improving cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

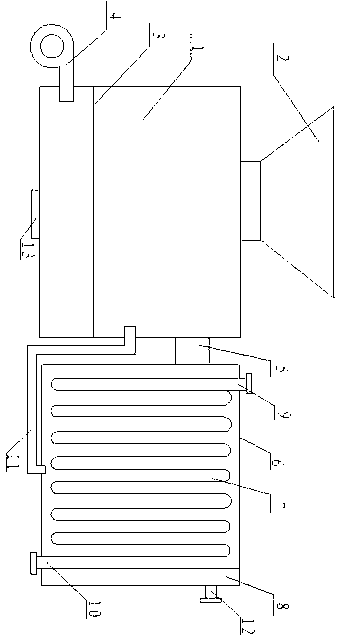

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0013] see figure 1 , the embodiment of the present invention comprises: cracking furnace 1, hopper 2 above cracking furnace 1, fire grate 3 in cracking furnace 1, blower 4 at the lower end of one side of cracking furnace 1 and regenerator 6 connected through cracking furnace 1 burner 5 The regenerator 6 is provided with a circulating water pipe 7 and a hot air chamber 8. One end of the regenerator 6 is connected to the burner 5, and the other end is connected to the hot air outlet 12. The pyrolysis gas produced by the cracking furnace 1 is burned and then transferred to the heat storage through the burner 5. The heat chamber 6 exchanges heat wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com