Electric spark processing working solution circulating system with self-cleaning function

A circulation system and working fluid technology, applied in the direction of electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor filtration accuracy, troublesome cleaning, frequent replacement of filter elements, etc., to achieve automatic cleaning, improve work efficiency, improve The effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

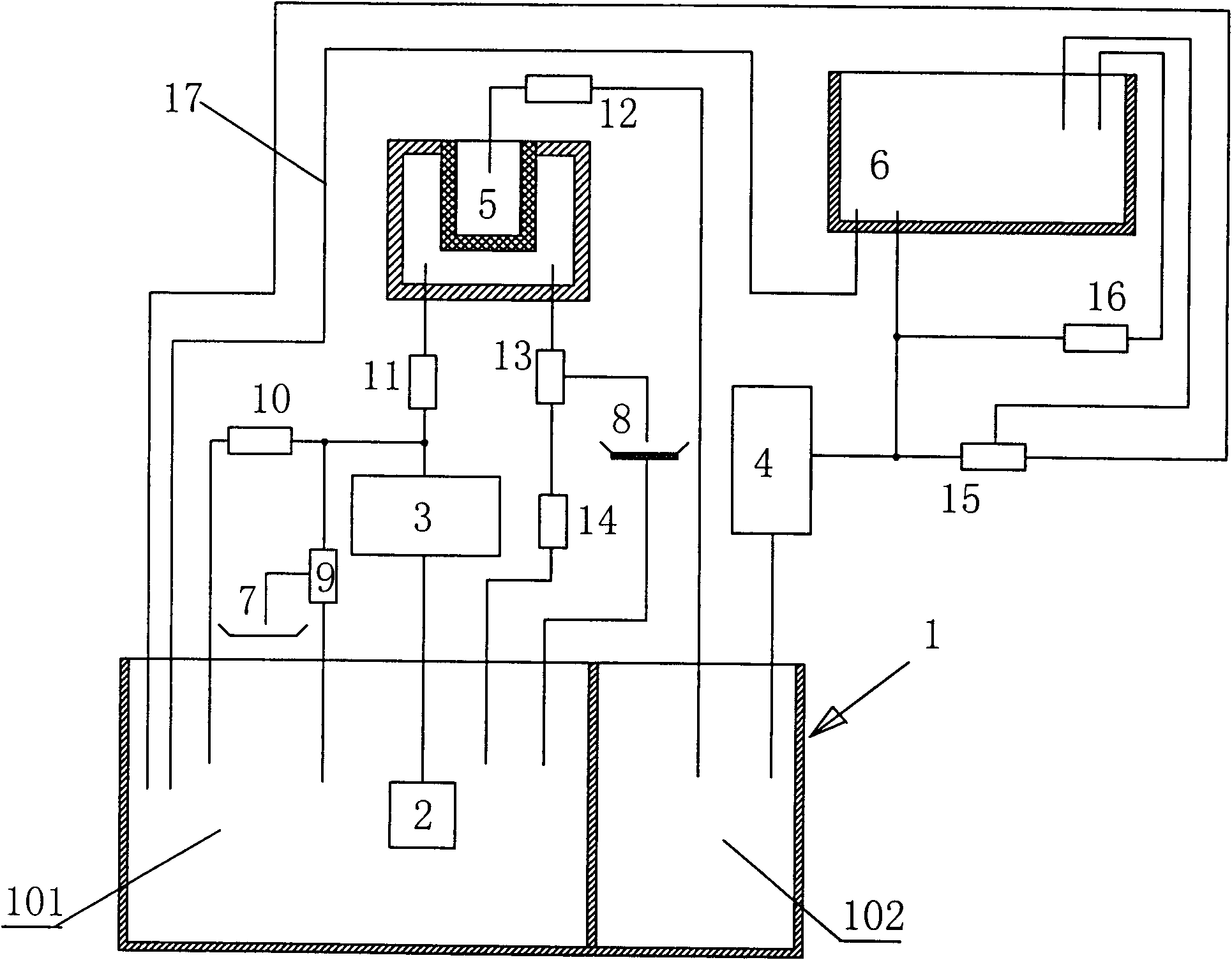

[0019] Such as figure 1 As shown, the EDM working fluid circulation system with self-cleaning function of the present invention is mainly composed of a liquid storage tank 1, a working fluid tank 6, a coarse filter 2, a cleaning filter 8, a filter pump 3, an upper liquid pump 4, a fine filter 5, various control valves 9-16 and pipelines; the position of the working fluid tank must be higher than that of the storage tank.

[0020] The EDM working fluid circulation system with self-cleaning function of the present invention divides the fluid storage tank into a dirty working fluid storage tank room for containing dirty working fluid and a clean working fluid storage tank room for clean working fluid. It can be installed independently, or as shown in the figure, a whole liquid storage tank can be separated into a dirty working fluid storage tank chamber 101 and a clean working fluid storage tank chamber 102 .

[0021] The EDM working fluid circulation system with self-cleaning f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com