Method and device for realizing connection of optical transceiver and main printed circuit board

A technology for printed circuit boards and optical transceiver devices, which is applied in the directions of printed circuits connected with non-printed electrical components, and assembling printed circuits with electrical components, which can solve difficult process quality control, low production efficiency and high production costs. problems, to achieve the effect of eliminating randomness and uncertainty, low cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

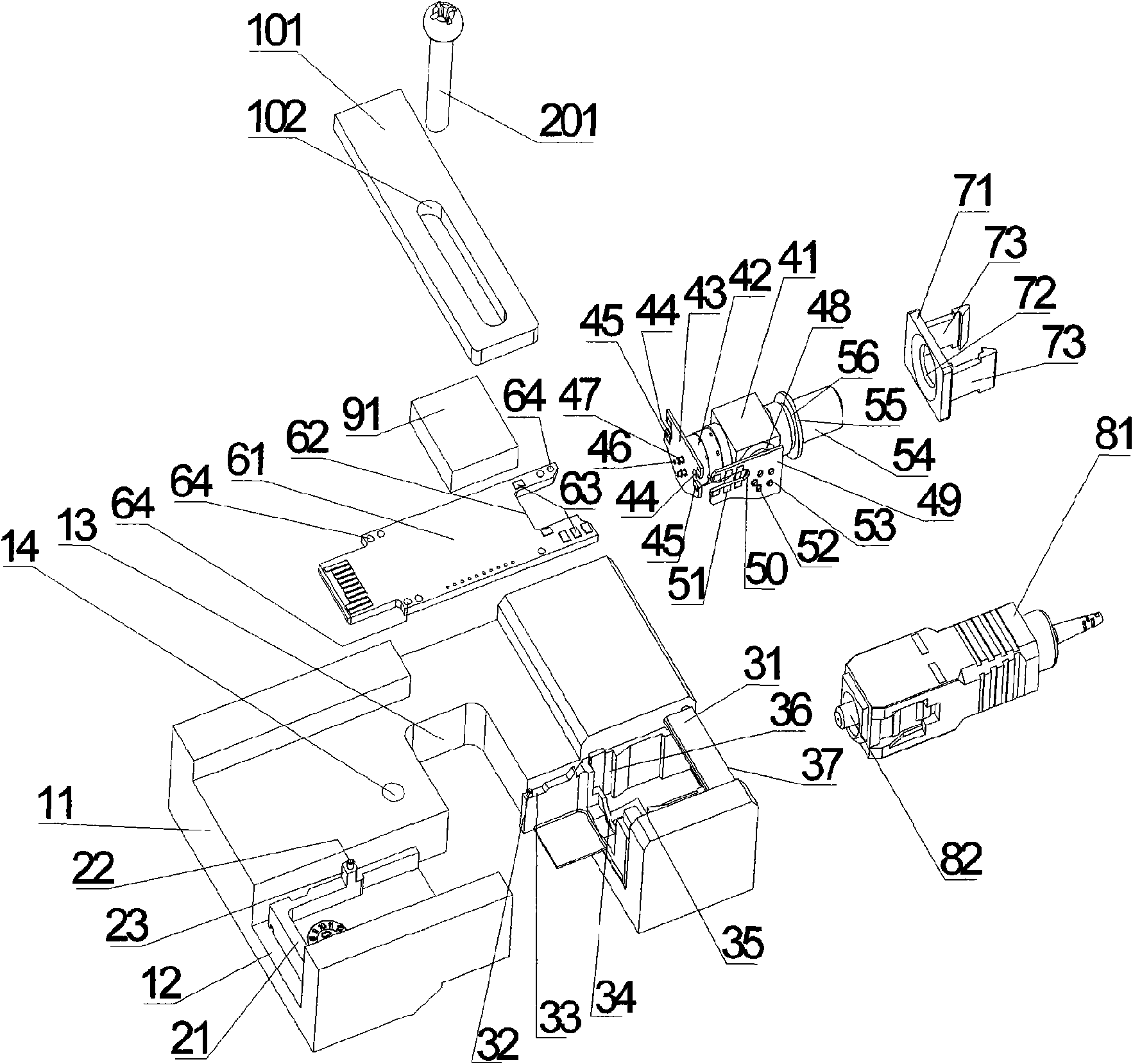

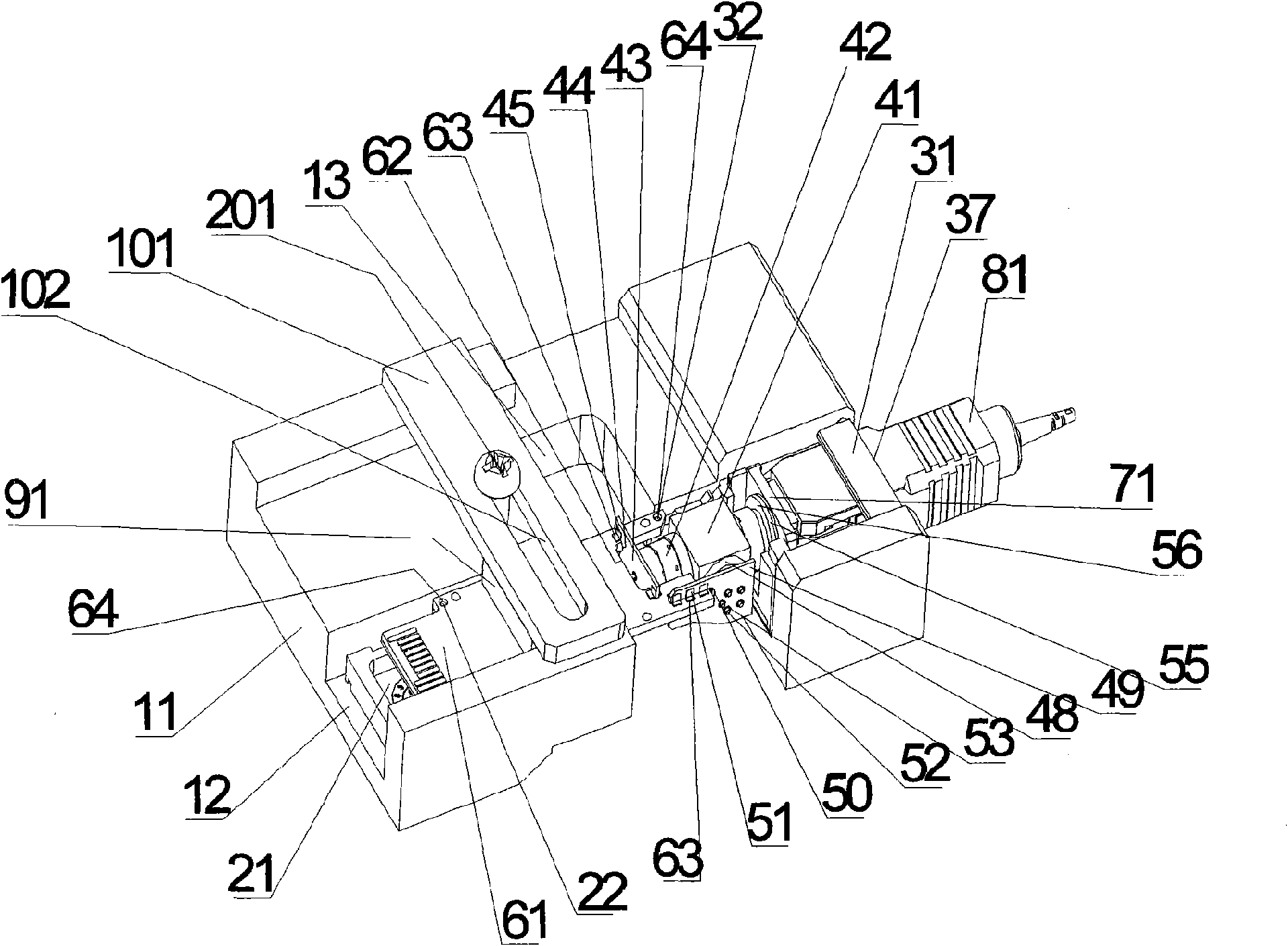

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

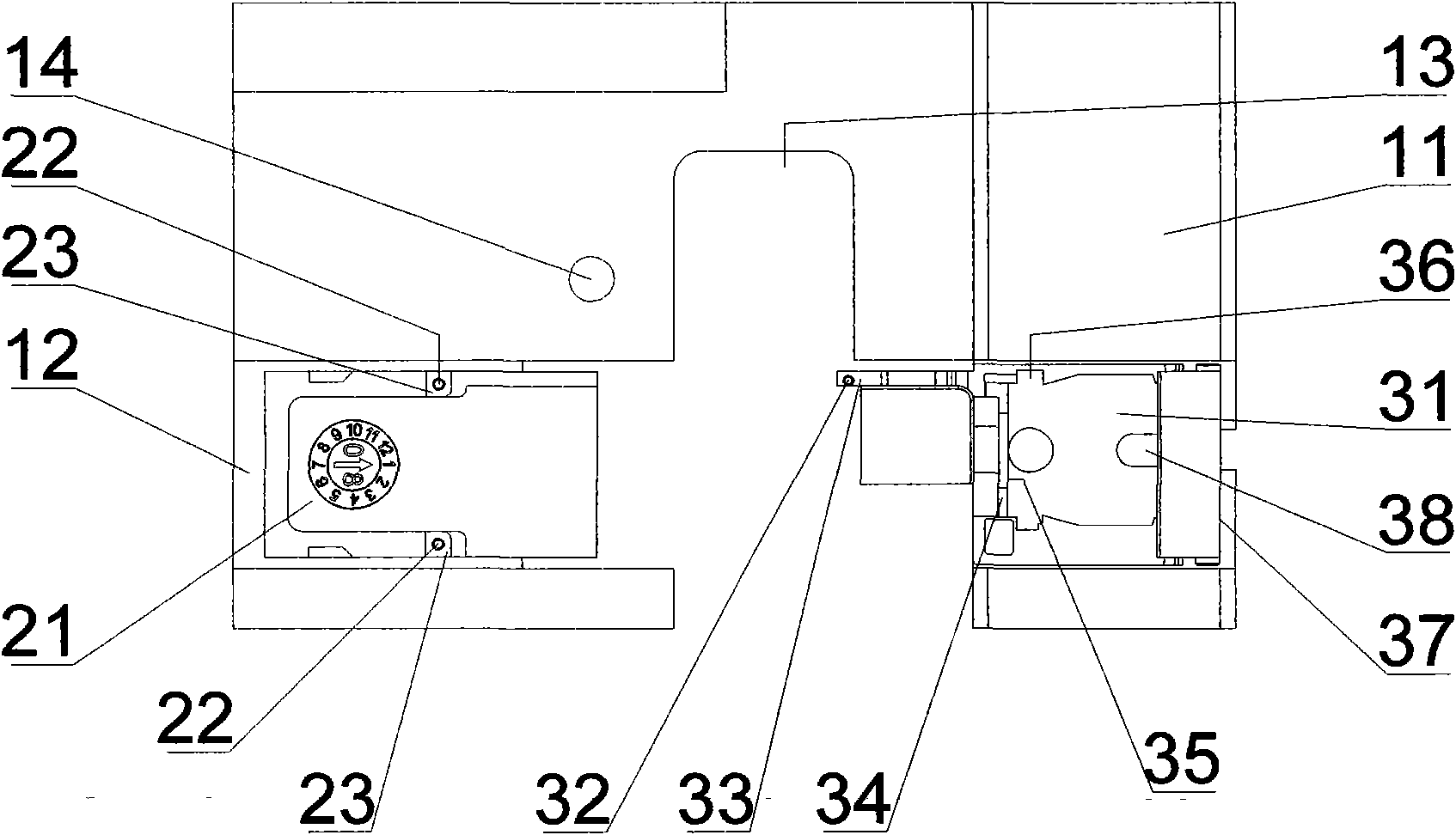

[0029] figure 1 It is a schematic top view of the base in the specific embodiment of the present invention. Such as figure 1 As shown, the base consists of a base table 11 , a rear positioning casting 21 and a front positioning casting 31 .

[0030] The main body of the base platform 11 is a rectangular parallelepiped structure, and a screw hole 14 is arranged near the middle part, and a rectangular slot 12 is arranged near the long side of the base 11 . The metal shell of the optical transceiver module is processed by casting technology. The metal shell of the optical transceiver module is glued in the rectangular groove 12 with super glue, and fixed with the base platform 11 as a whole. From the side of the base platform 11 A notch 13 is machined to cut the metal shell into two sections, a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com