Integrated surface acoustic wave wireless temperature sensor

A wireless temperature and surface acoustic wave technology, which is applied to thermometers, thermometers, instruments, etc. with physical/chemical changes, can solve the problems of time-domain delay signal extraction, low signal-to-noise ratio, and large device loss. Compensation and sensitivity improvement, improved signal-to-noise ratio performance, and reduced device losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

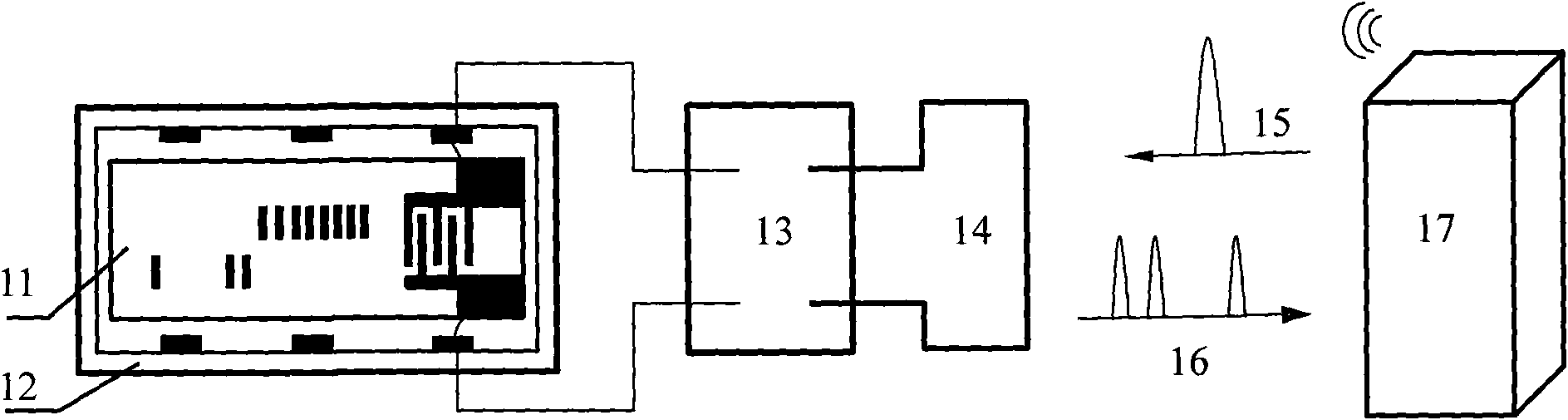

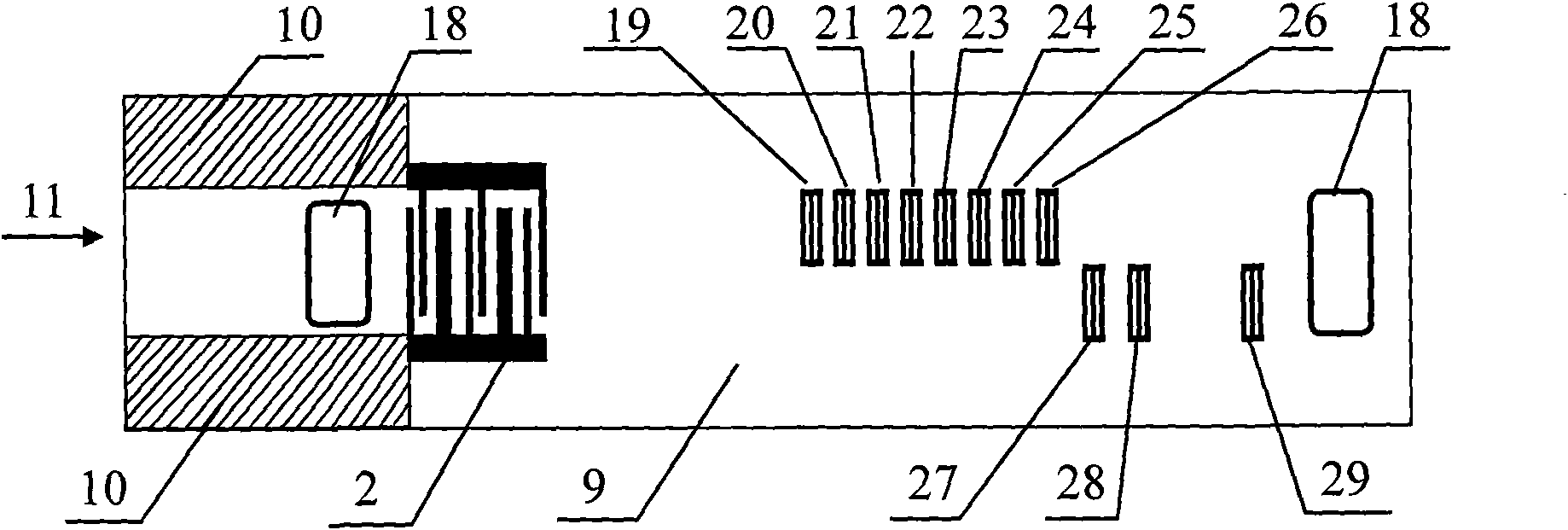

[0053] refer to Figure 2a , making an integrated SAW temperature sensor, including: a SAW reflective delay line 11, a surface mount component 12, and an impedance matching network 13 between the SAW reflective delay line 11 and the wireless antenna 14.

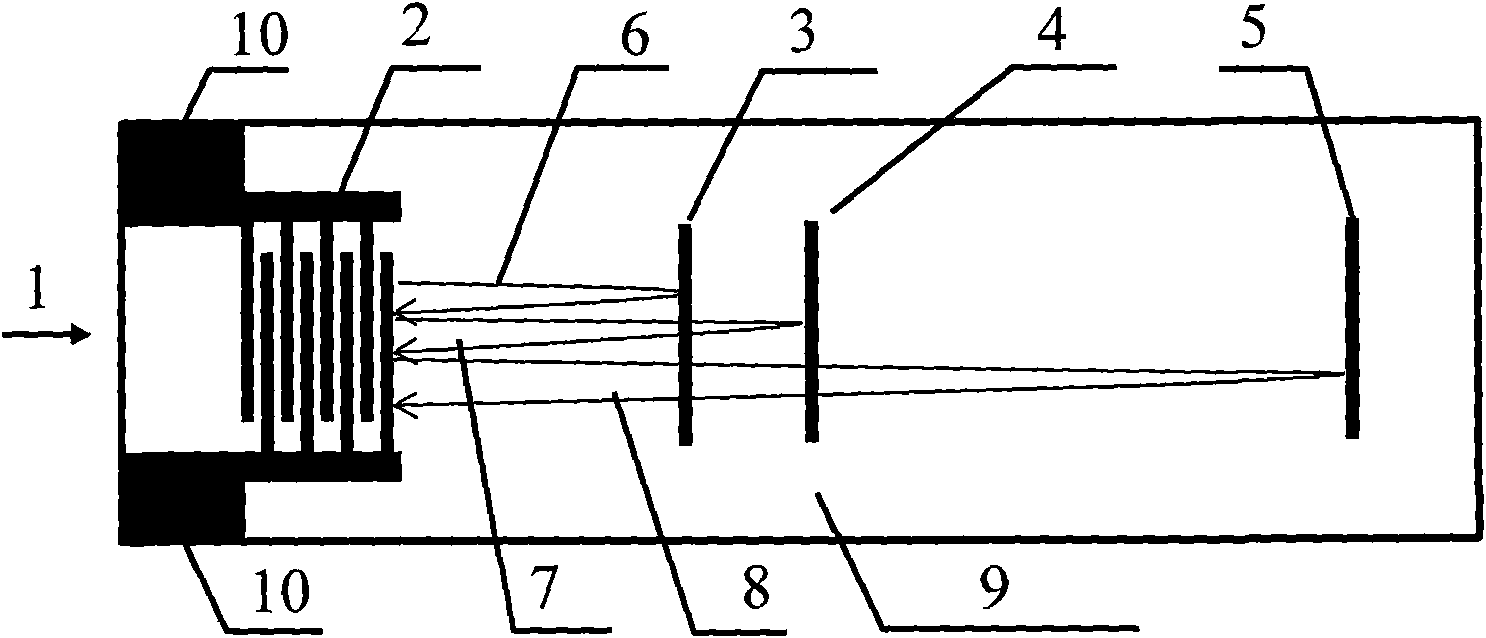

[0054] refer to Figure 2b , the SAW reflective delay line 11 of the embodiment of the present invention consists of a piezoelectric substrate 9, and a transducer made on the piezoelectric substrate 9 (the transducer of this embodiment adopts a single-phase electrode width control The unidirectional transducer, namely EWC / SPUDT)2 is composed of eleven short-circuit grid reflectors. The SAW reflective delay line 11 is hermetically packaged with a surface mount component 12 to protect the piezoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com