Electric stove metal balk cargo vibration material delivering and airflow dynamic packing device

A dynamic sealing and metal technology, applied in the field of machinery, can solve the problems of large equipment maintenance, low reliability, and increased height of electric furnace equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

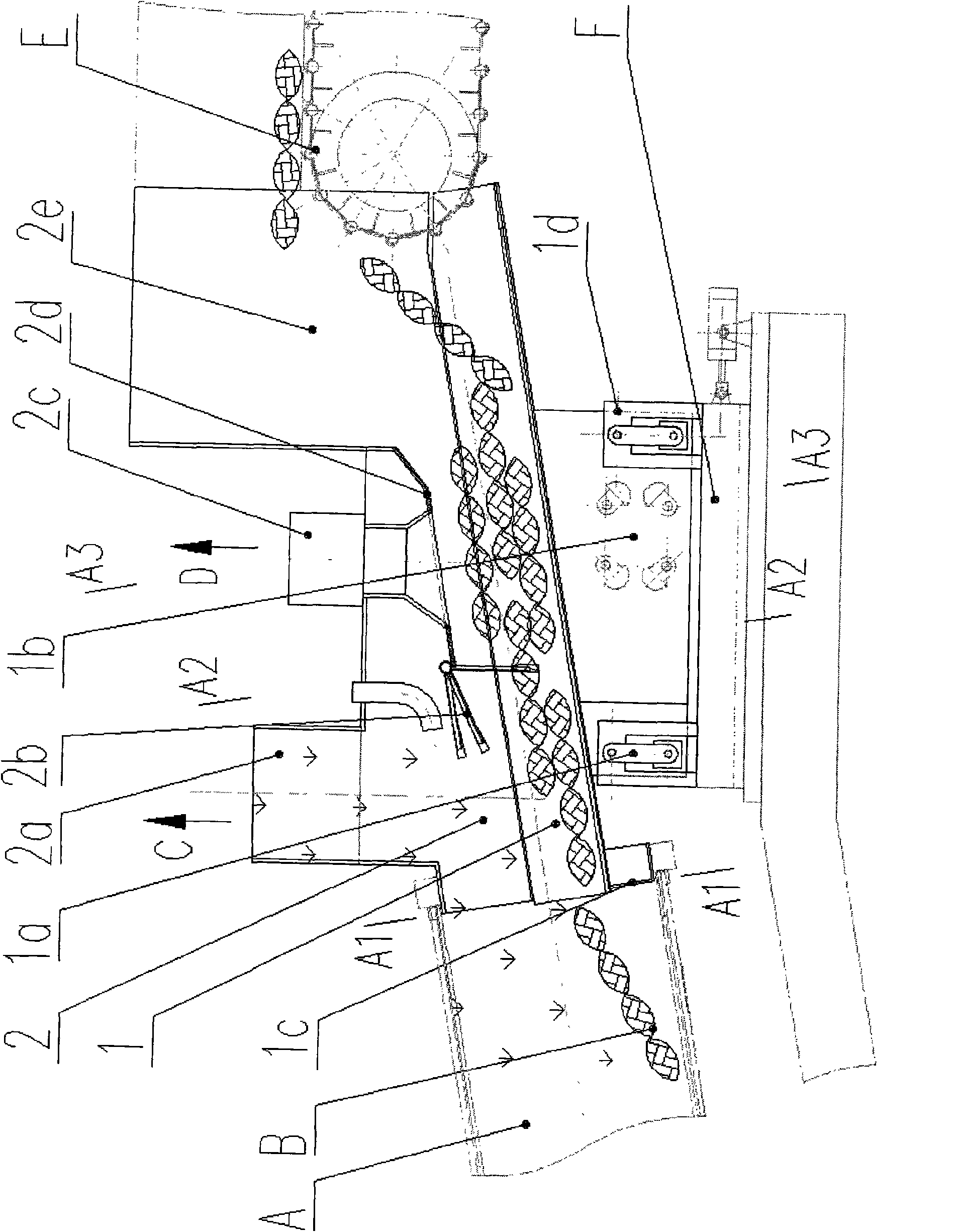

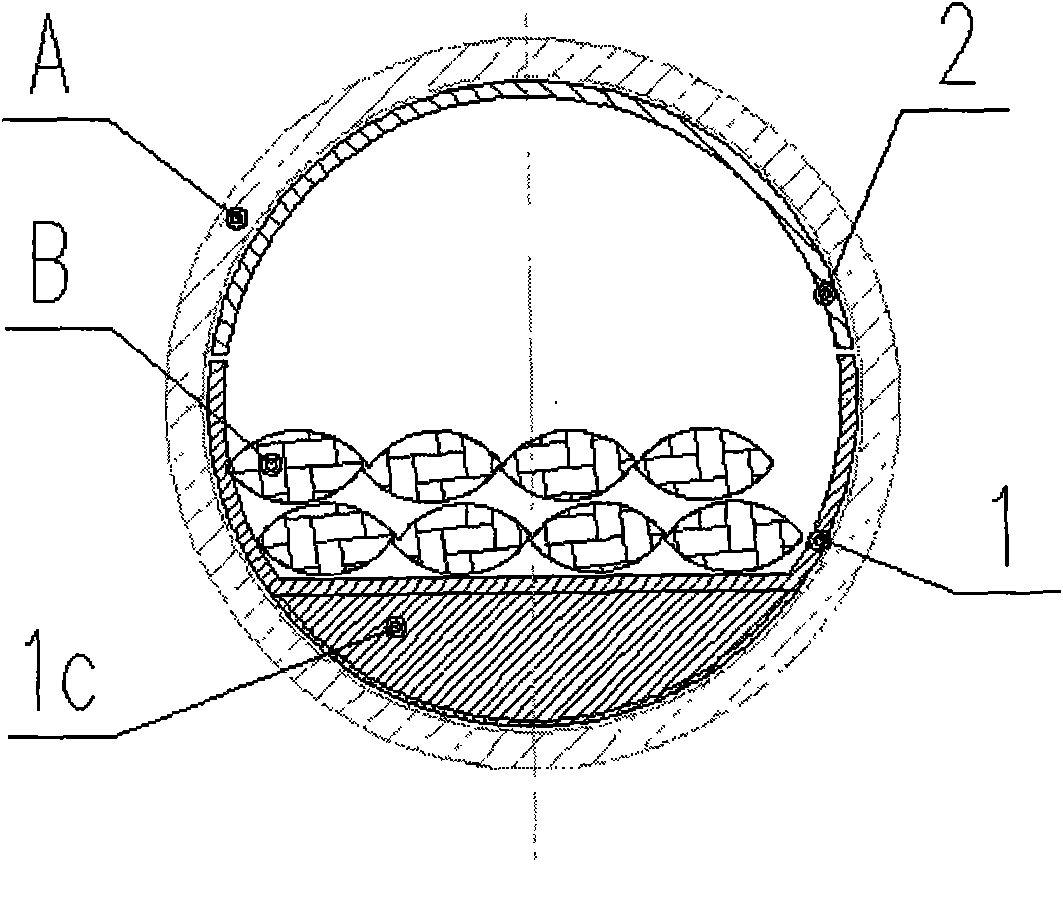

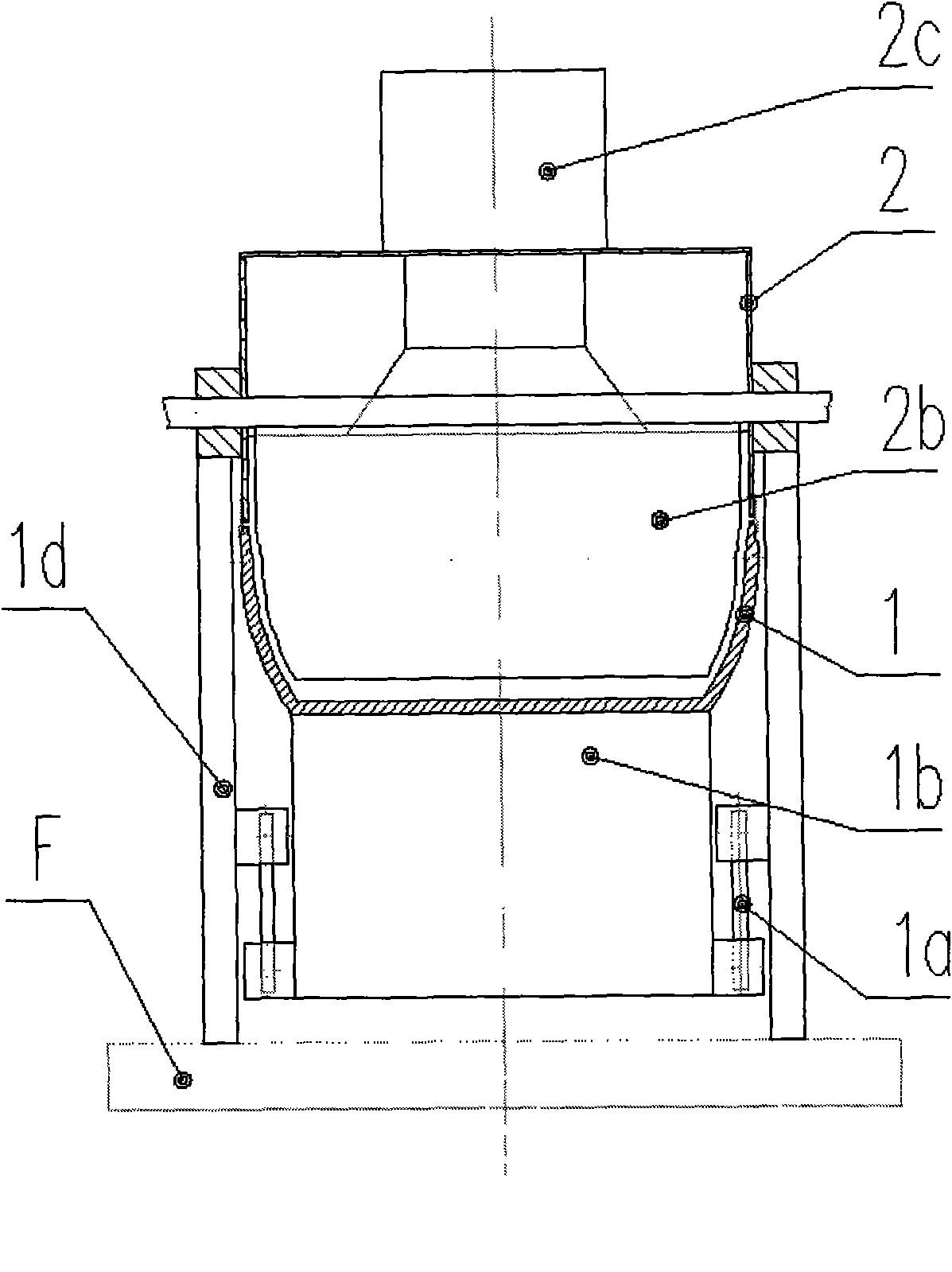

[0014] The smoking guide material sealing cover 2 is fixedly installed on the support 1d, the vibration feeding tank 1 and the smoking guide material sealing cover 2 are installed on the mobile platform F through the bracket 1d, and the vibration excitation device 1b is hung on the On the support 1d. The vibrating feeding tank 1 is covered with a smoke guide material sealing cover 2, and its duct partition 2d and the bottom of the vibrating feeding tank 1 form a vibrating feeding and gas dynamic sealing duct, and there is a swing adjustment partition at the front of the duct partition 2d 2b: The vibrating feeding tank 1 is installed obliquely, and the cooperation of the two at the head forms a circle, and is inserted into the preheating tank A of the metal material drum to fit with it. Metal material drum preheating groove A is installed obliquel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com