Full filter lampblack purifier

A technology of oil fume purifier and range hood, which is applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc. It can solve the problems affecting environmental sanitation, and achieve the effects of avoiding environmental pollution, low production cost, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

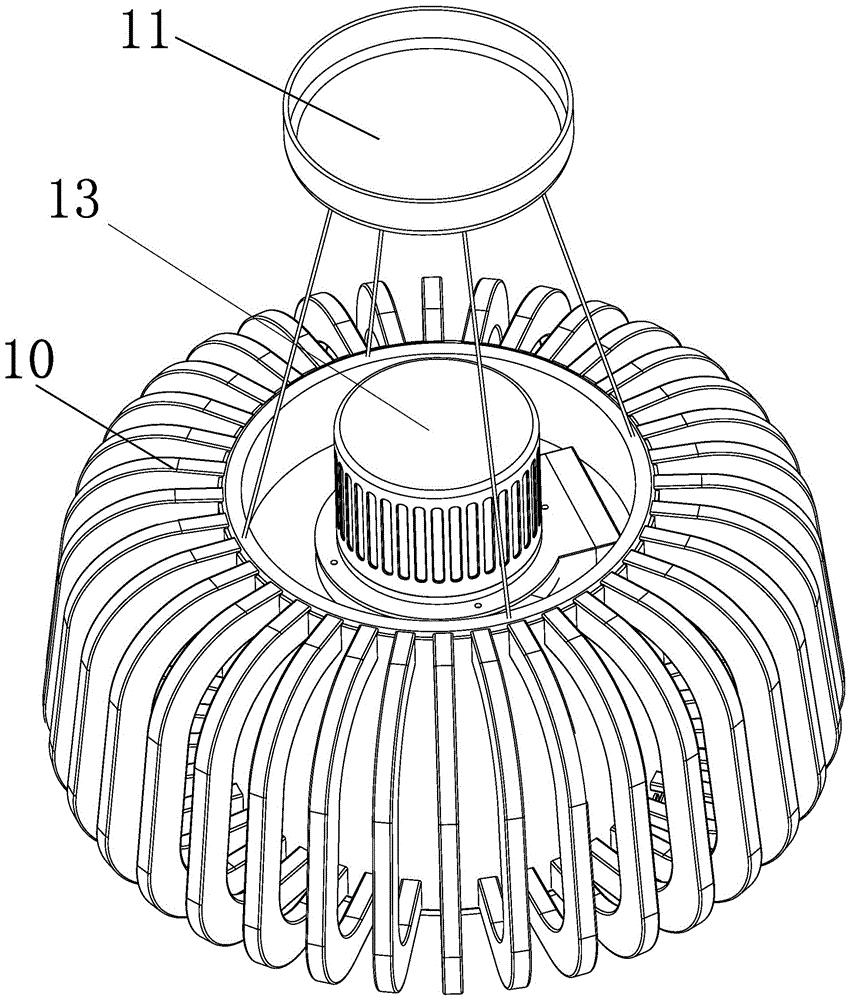

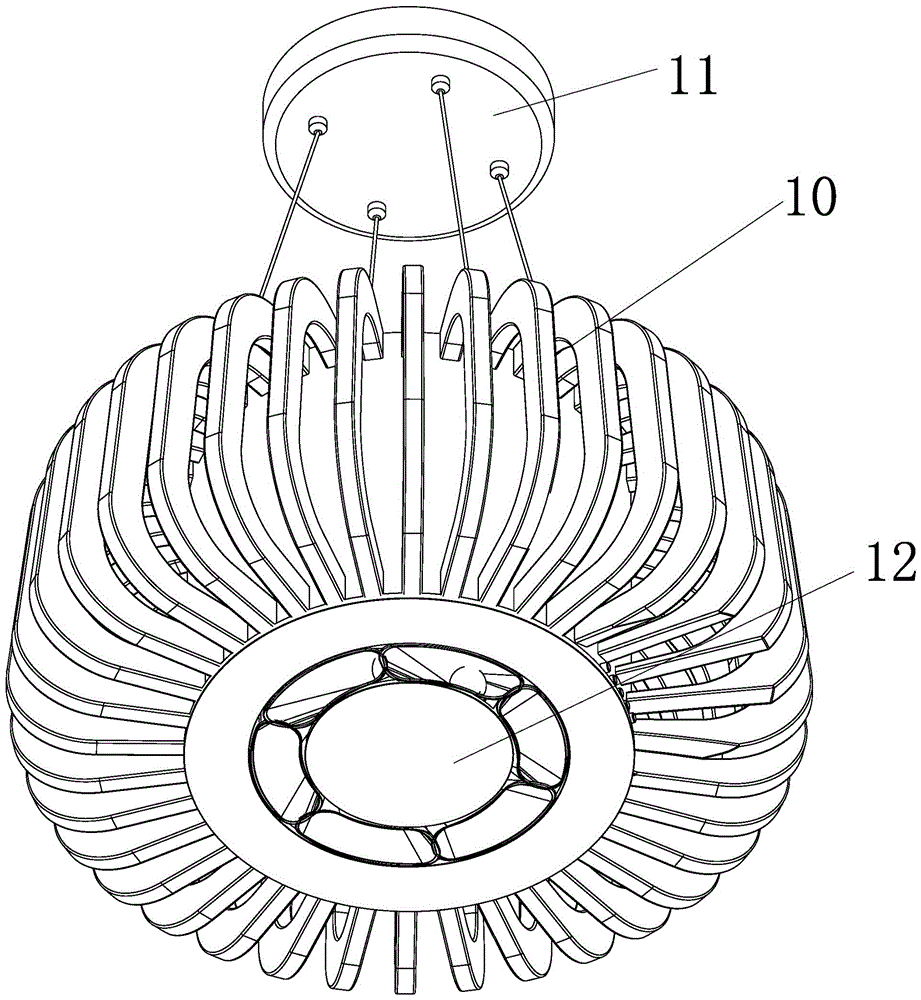

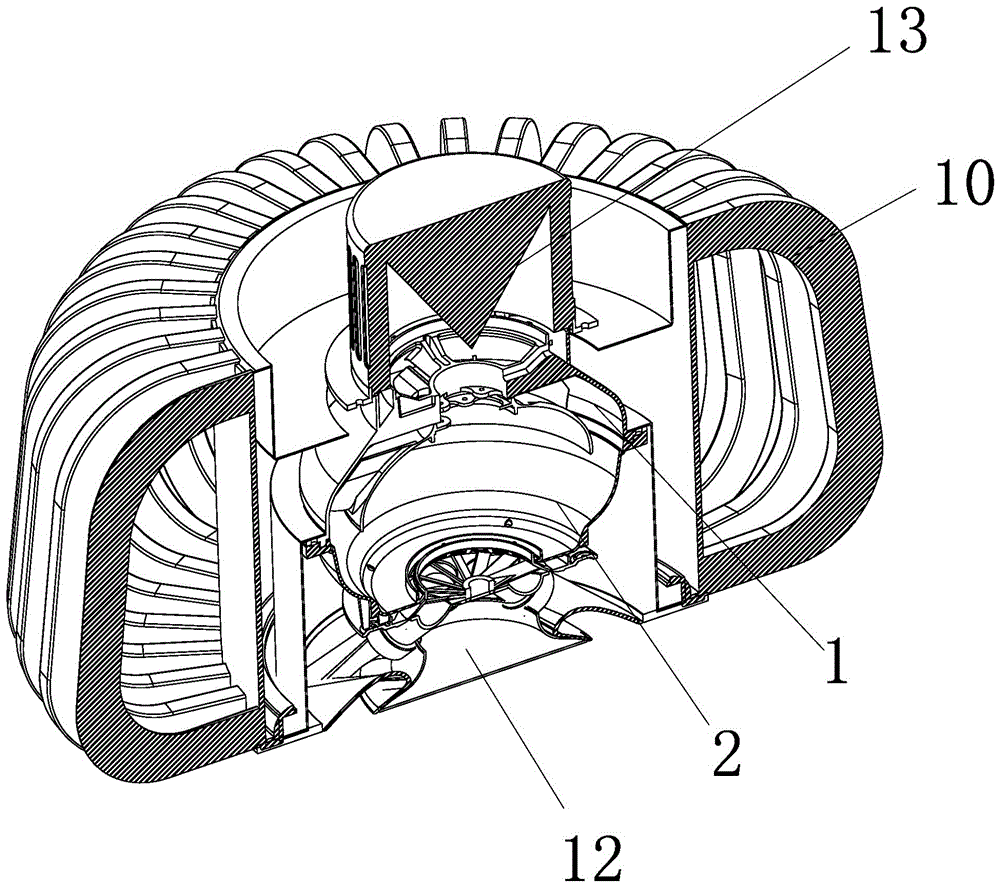

[0031] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A full-filter oil fume purifier, which includes a casing 10 and a hanging pan 11 connected thereto, the hanging pan 11 is connected with a fixture to suspend and fix the range hood, and is characterized in that: the casing 10 is provided with a guide The air device 12, the fan module, and the filter module 13 are connected sequentially from bottom to top, wherein:

[0032] The air deflector 12 includes a fixed plate 121 and an oil collecting pan 122 installed therein. A number of air guide pipes 123 are evenly distributed on the periphery of the oil collecting plate 122, and the air guiding pipes 123 are located between the fixed plate 121 and the oil collecting plate 122. and connected to the smoking port 4 of the fan module;

[0033] The fan module includes: an upper volute 1 and a lower volute 2, the upper and lower volutes are butted and fastened to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com