System for cultivating microalgae with waste water

A technology for microalgae and waste water, which is applied in the field of systems for culturing microalgae by using waste water, can solve the problems of increasing the cost of microalgae cultivation, consuming large energy, and consuming large water sources, saving water and energy, being beneficial to environmental protection, and reducing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

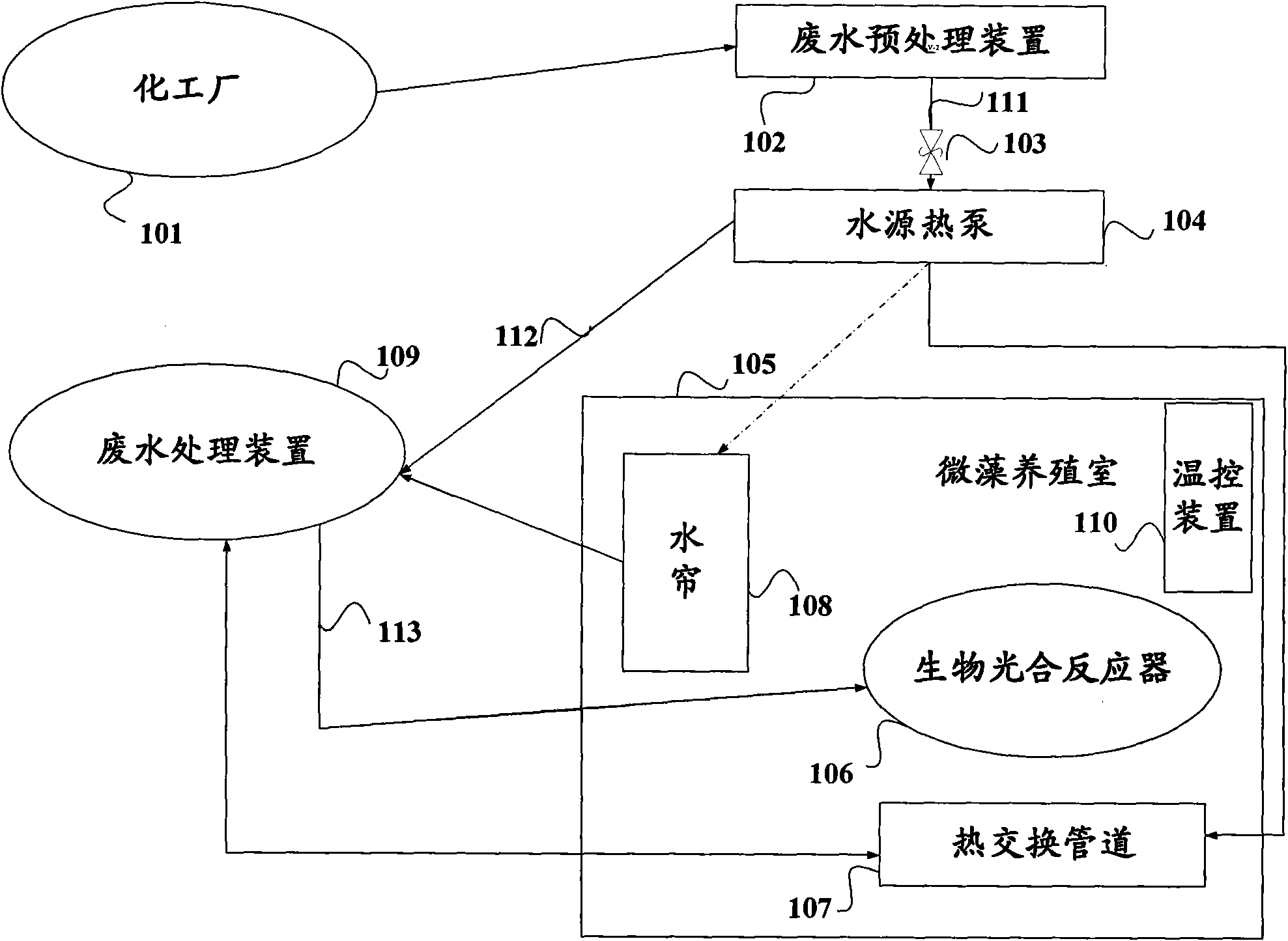

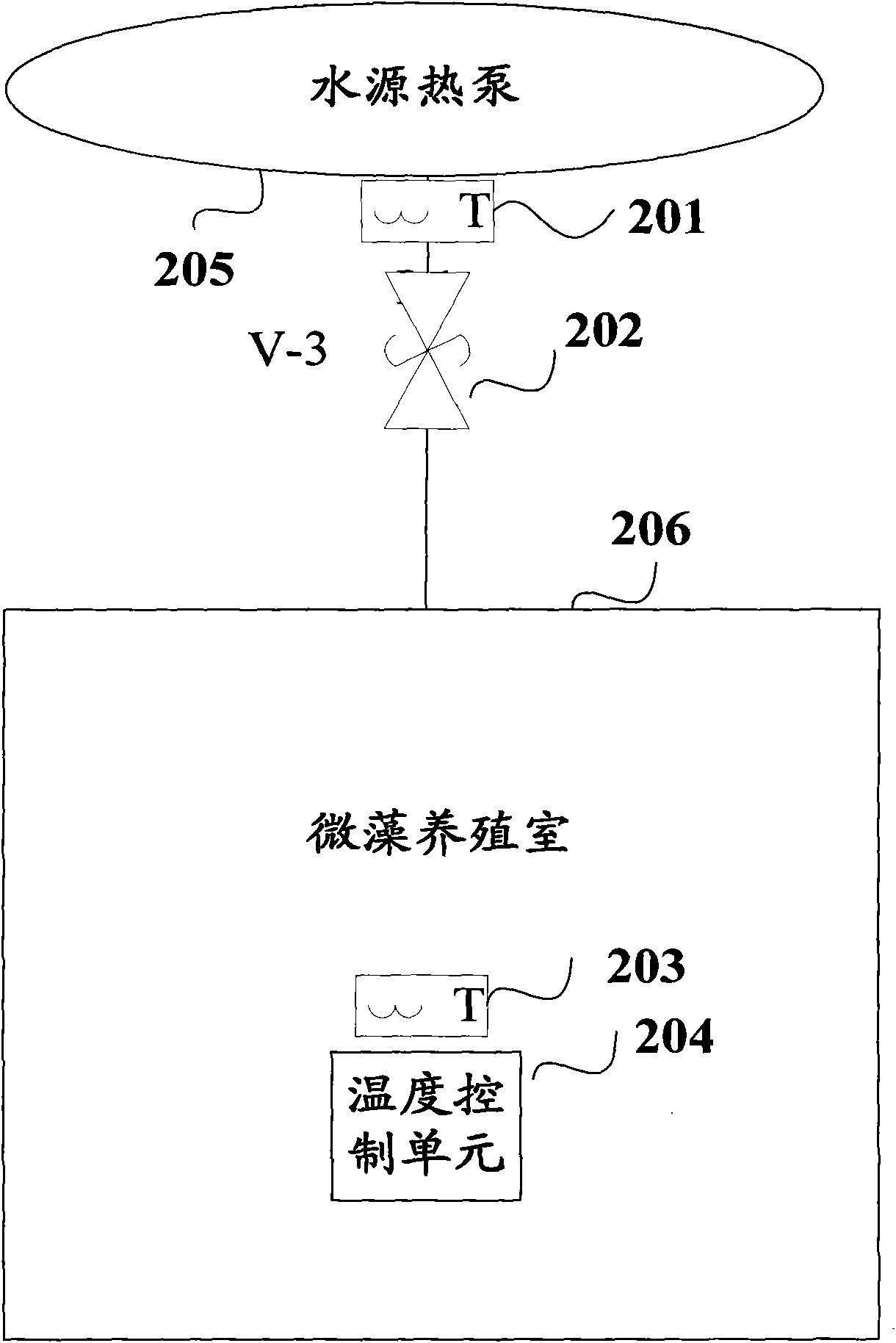

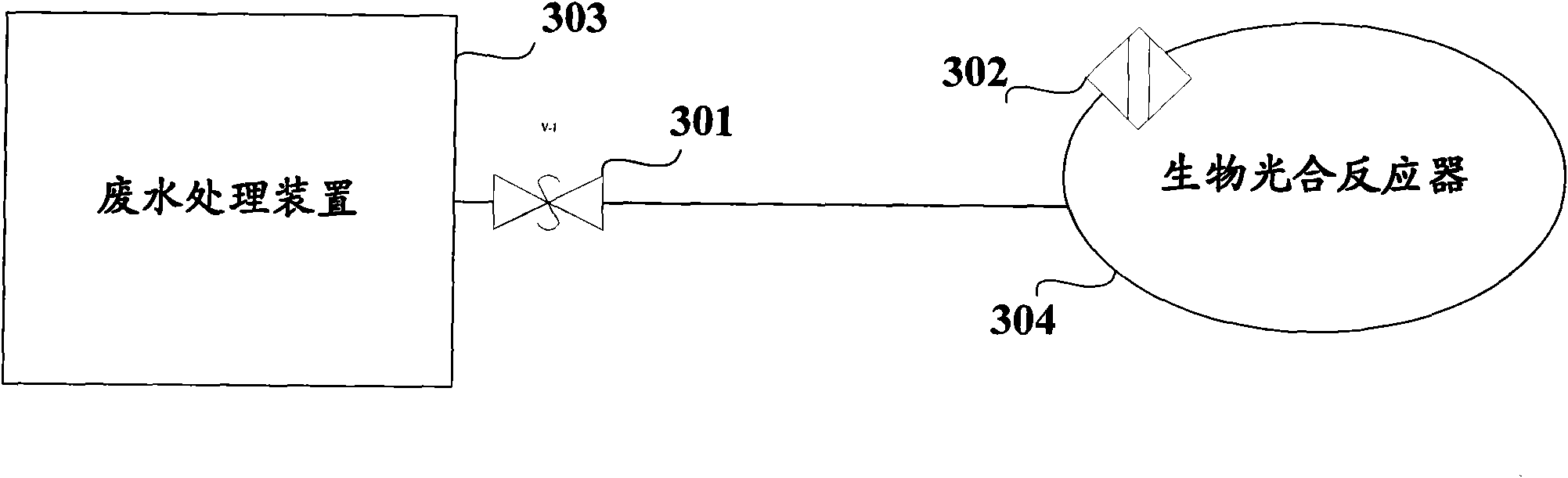

[0021] The method and device in the embodiment of the present invention will be described below with reference to the accompanying drawings. The drawings are only used to help understand the solutions of the embodiments, and may not be limited to the forms shown in the drawings in various implementations.

[0022] The waste water used in the embodiment of the present invention is chemical plant waste water. The industrial wastewater discharged from chemical plants (especially coal chemical plants) usually has an outlet temperature of 30-35°C and contains a large amount of inorganic salts such as nitrogen and phosphorus. By adopting the technical solution of the invention, the thermal energy of the waste water can be utilized, and the inorganic salts such as nitrogen and phosphorus in the waste water can be used for microalgae culture, thereby reducing the cost of microalgae culture and being conducive to environmental protection.

[0023] The cultivation of microalgae is carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com