Synthesis method of cefradine

A synthesis method and technology of cefradine, applied in the field of drug synthesis, can solve problems such as affecting the crystal form and product stability of cefradine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Condensation

[0025] Add 75g of dihydrophenylglycine sodium salt, 400ML of dichloromethane, 20ML of DMA, and 0.1ML of 4-picoline into a 1000ML three-necked bottle; cool down to -20~-25°C, and add 49.0g of carbonyldiimidazole in portions , the reaction is exothermic, the speed of addition should not be too fast, and the temperature should not be higher than -20°C. The reaction was stirred at ℃ for 120 minutes, and the condensation reaction was completed.

[0026] 2. Hydrolysis and decolorization

[0027] Pour the condensation solution into a 2000ML beaker, start stirring, add 300ML of purified water, DMA32ML into the 2000ML beaker, stir evenly, control the temperature at 29-33°C, adjust the pH value to 0.6-0.8 with concentrated hydrochloric acid, then add the hydrolyzate In the separating funnel, let it rest fully, remove the dichloromethane phase, collect the water phase into a 500ML beaker, add an appropriate amount of activated carbon, stir for 10 minutes, and f...

Embodiment 2

[0033] Add 70g of dihydrophenylglycine sodium salt, 400ML of dichloromethane, 25ML of DMF, and 0.2ML of 4-picoline into a 1000ML three-necked bottle; cool down to -20~-25℃, and add 49.8g of carbonyldiimidazole in portions , the reaction is exothermic, the speed of addition should not be too fast, and the temperature should not be higher than -15°C. The reaction was stirred at ℃ for 120 minutes, and the condensation reaction was completed.

[0034] Post-reaction treatment such as crystallization, steps such as washing and drying are the same as in Example 1.

Embodiment 3

[0036] Add 82g of dihydrophenylglycine sodium salt, 400ML of chloroform, 30ML of DMA, and 0.3ML of 4-picoline into a 1000ML three-necked flask; cool down to -20~-25°C, add 63.3g of carbonyldiimidazole in portions, and react Exothermic, the speed of addition should not be too fast, the temperature should not be higher than -15°C, after the dropwise addition, control the temperature at -25~-30°C, keep it for 45 minutes, then add 50g of 7-ADCA, at -20~-25°C The reaction was stirred for 120 minutes, and the condensation reaction was completed.

[0037] Post-reaction treatment such as crystallization, steps such as washing and drying are the same as in Example 1.

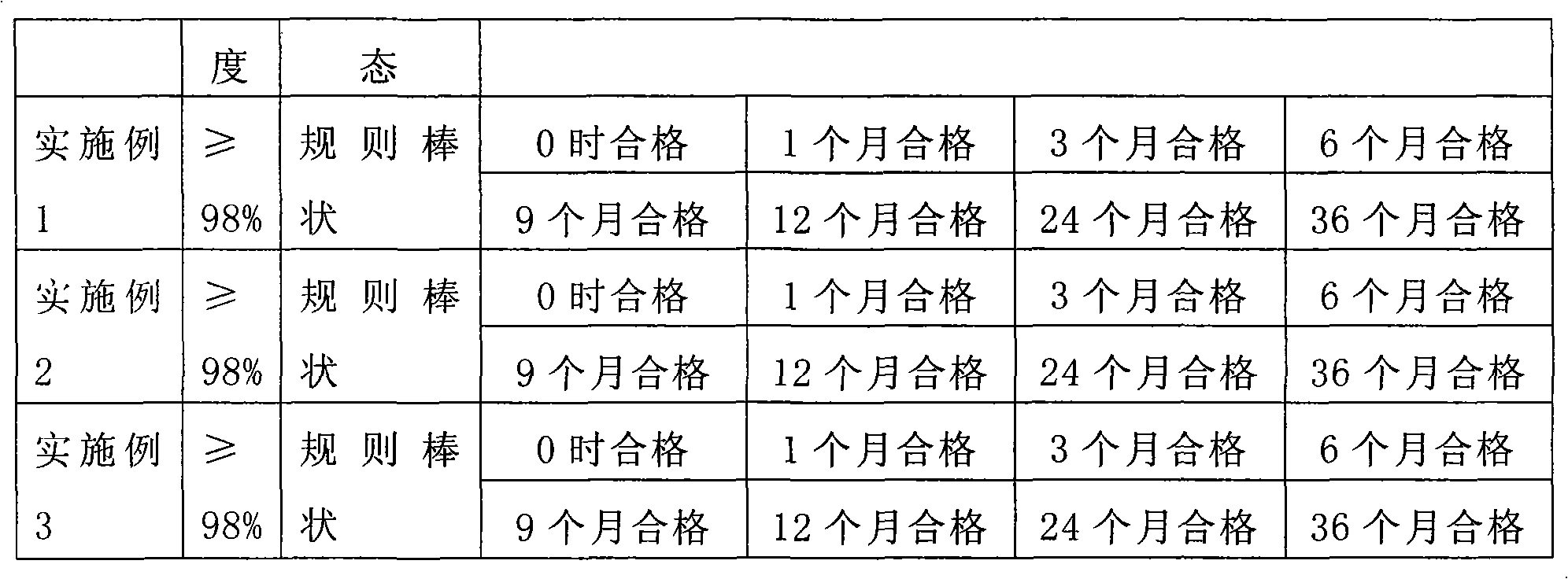

[0038] The comparison of technical quality indicators of the above implementation schemes is shown in the table below:

[0039]

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com