Precise polishing method of stainless steel substrate

A precision polishing and stainless steel technology, which is applied to polishing compositions containing abrasives, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as no related reports, and achieve smooth and smooth surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

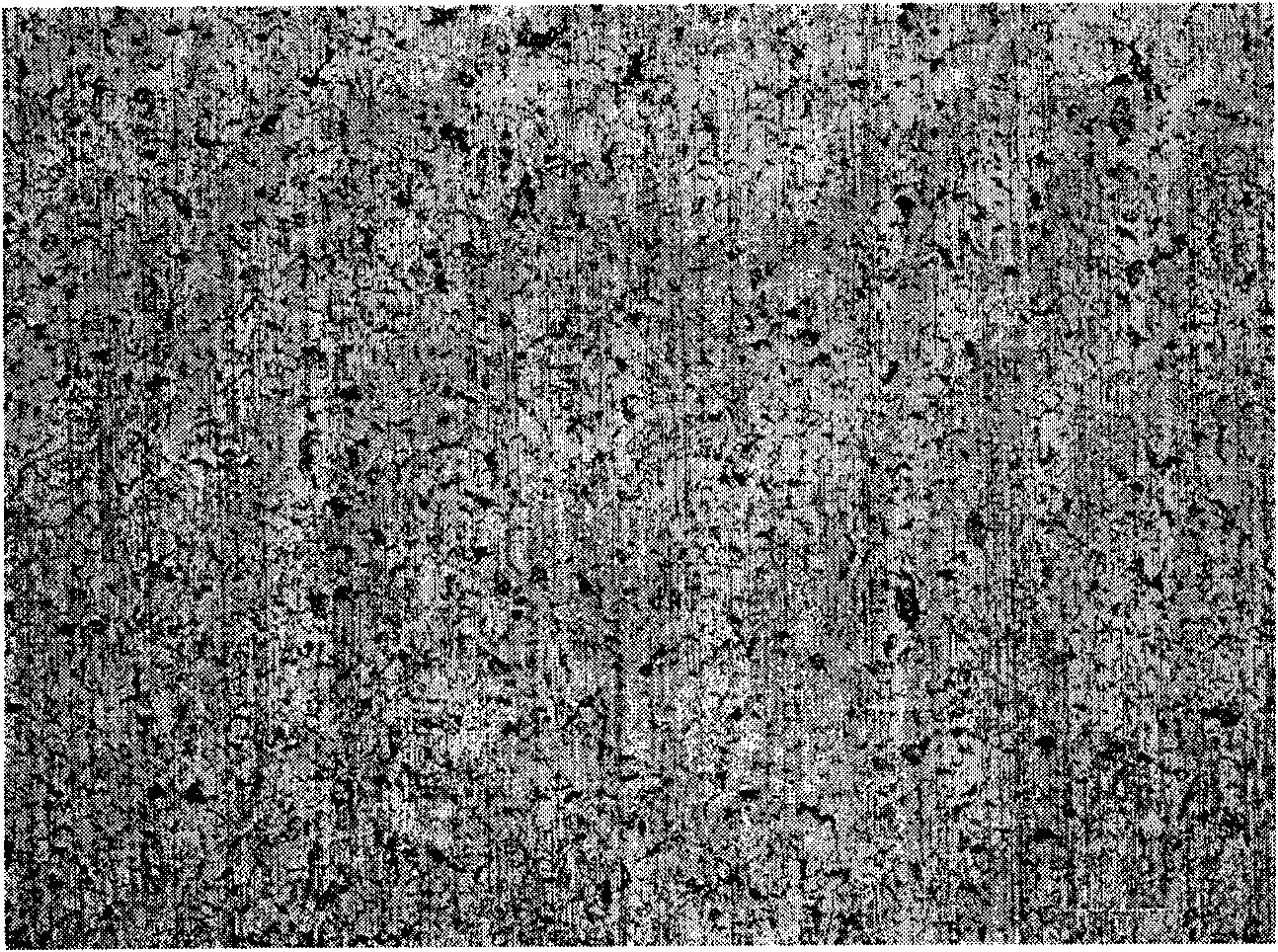

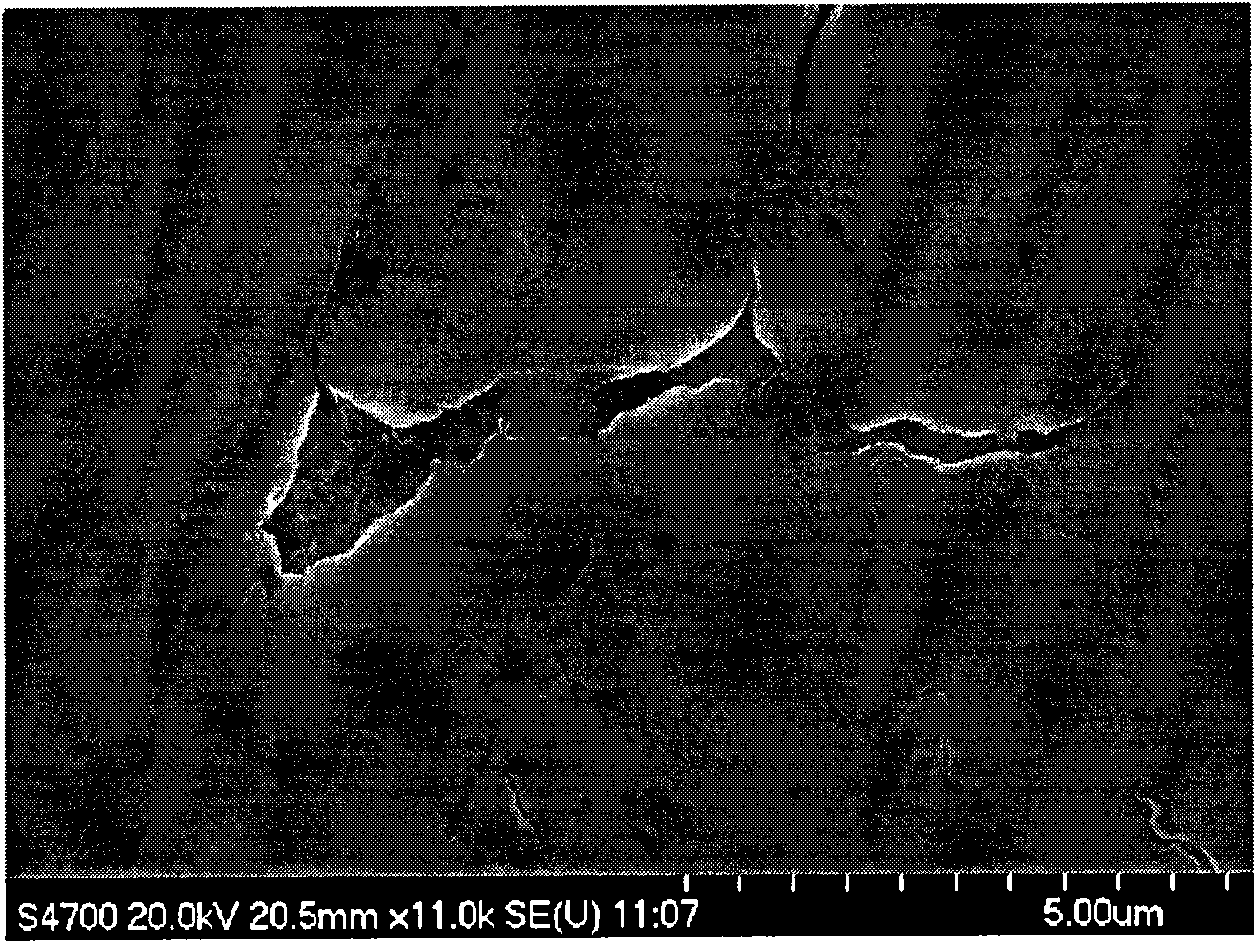

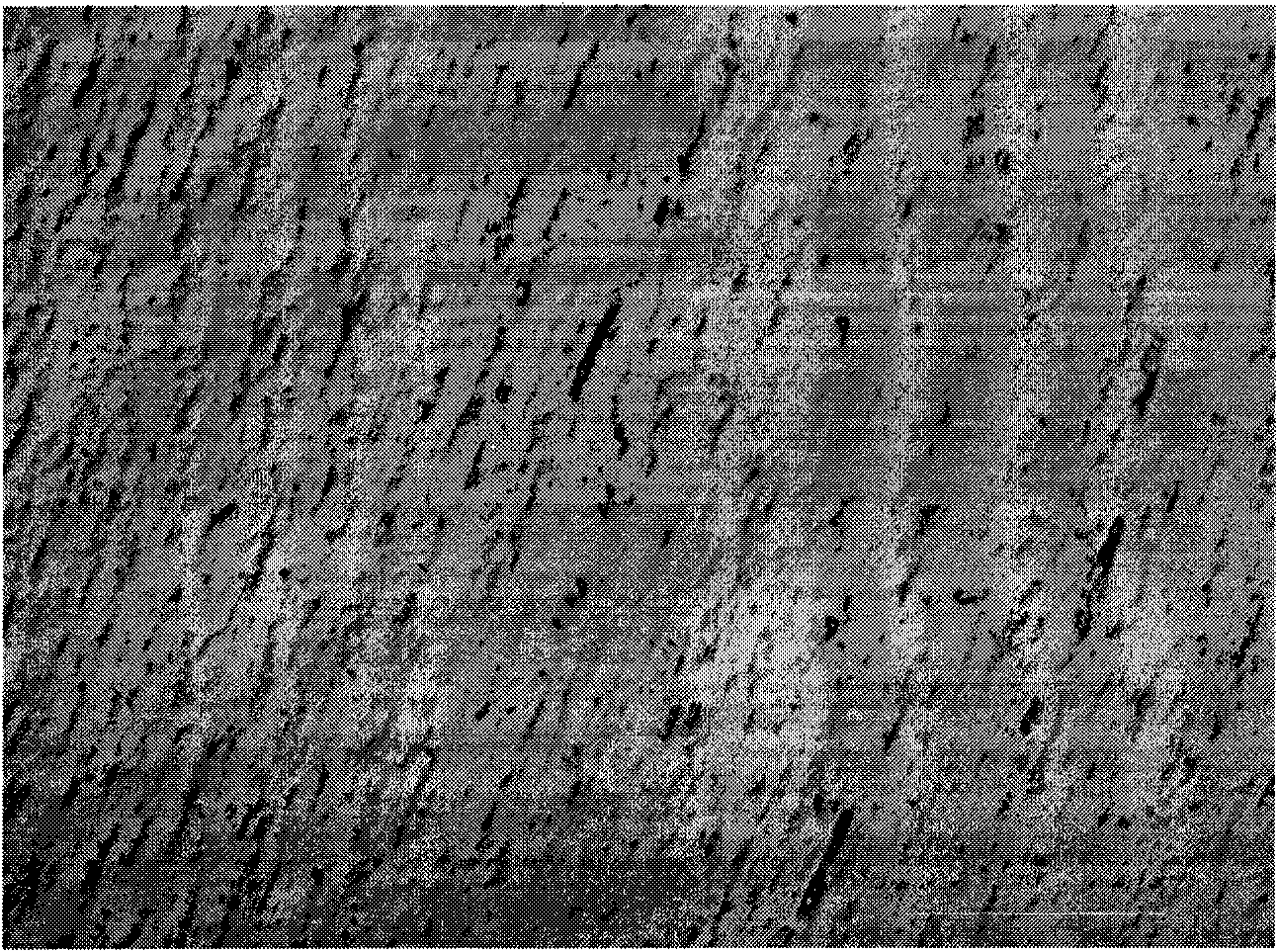

Image

Examples

Embodiment 1

[0033] (1) Preparation of polishing liquid

[0034] Silicon oxide particles: 10wt%; oxidizing agent Fe(NO 3 ) 3 : 5wt%; inhibitor BTA: 0.2wt%; complexing agent glycerol: 0.5wt%; pH regulator CH 3 COOH: 0.2wt%; the rest is water;

[0035] (2) The stainless steel substrate 5 to be polished is fixed on the bottom of the polishing head 4, and the polishing head 4 is acted on the polishing table 6 by the pressurizing device 7, and the polishing table 6 and the polishing head 4 rotate under the drive of the rotating device, and polish simultaneously The liquid 2 is transported to the surface of the polishing pad 1, so that the polishing liquid 2, the polishing pad 1 and the stainless steel substrate 5 are in full contact;

[0036] Polishing process parameters: the speed of the polishing table 6 is 40-200 rpm; the speed of the polishing head 4 is 40-200 rpm, and the speed of the polishing head 4 and the polishing table 6 are approximately equal; the stainless steel substrate 5 act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com