Analyzer, analysis method, and analysis program

An analysis device, analysis method technology, applied in the field of analysis program, capable of solving problems such as difficulty in sufficiently suppressing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

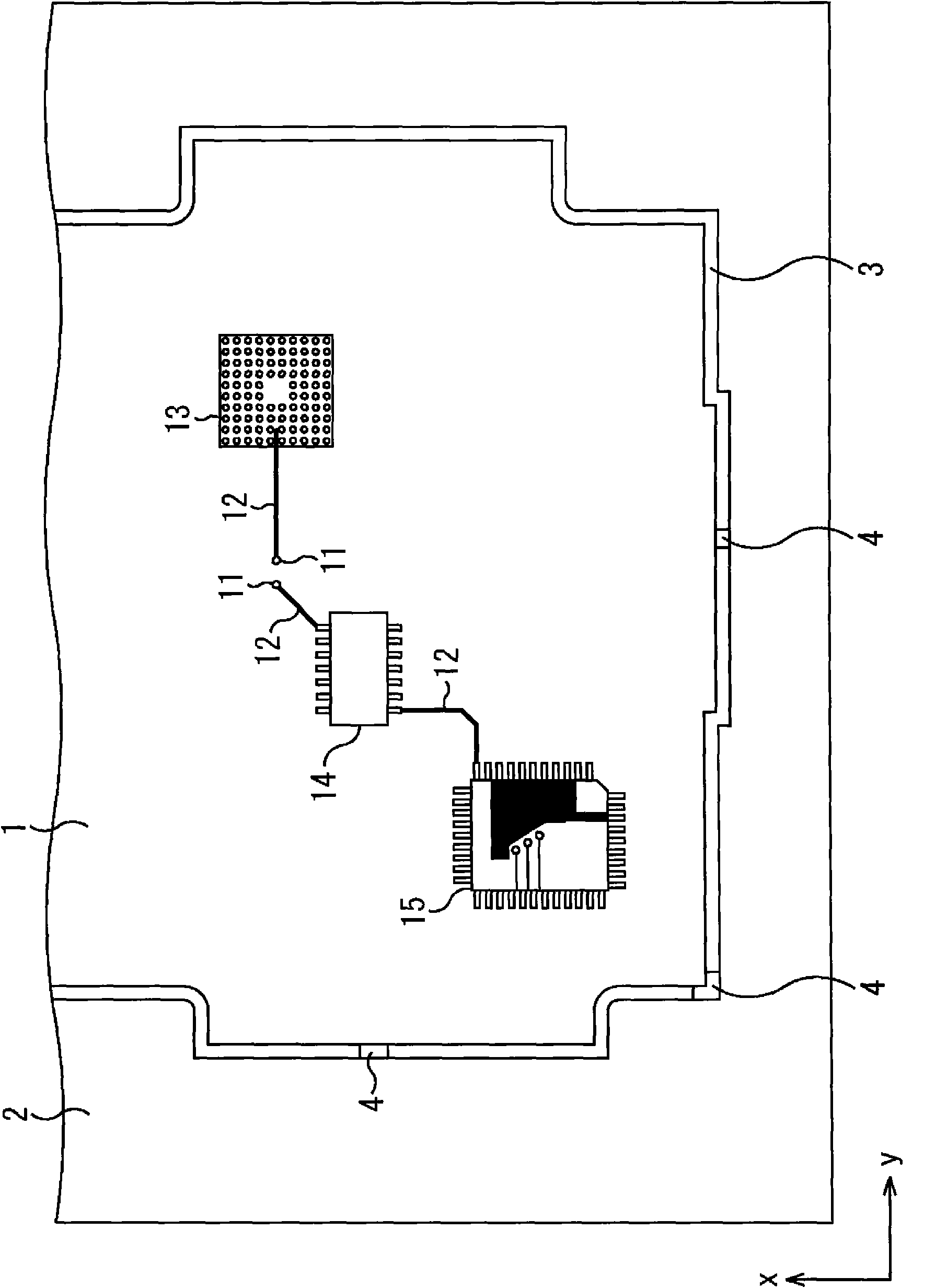

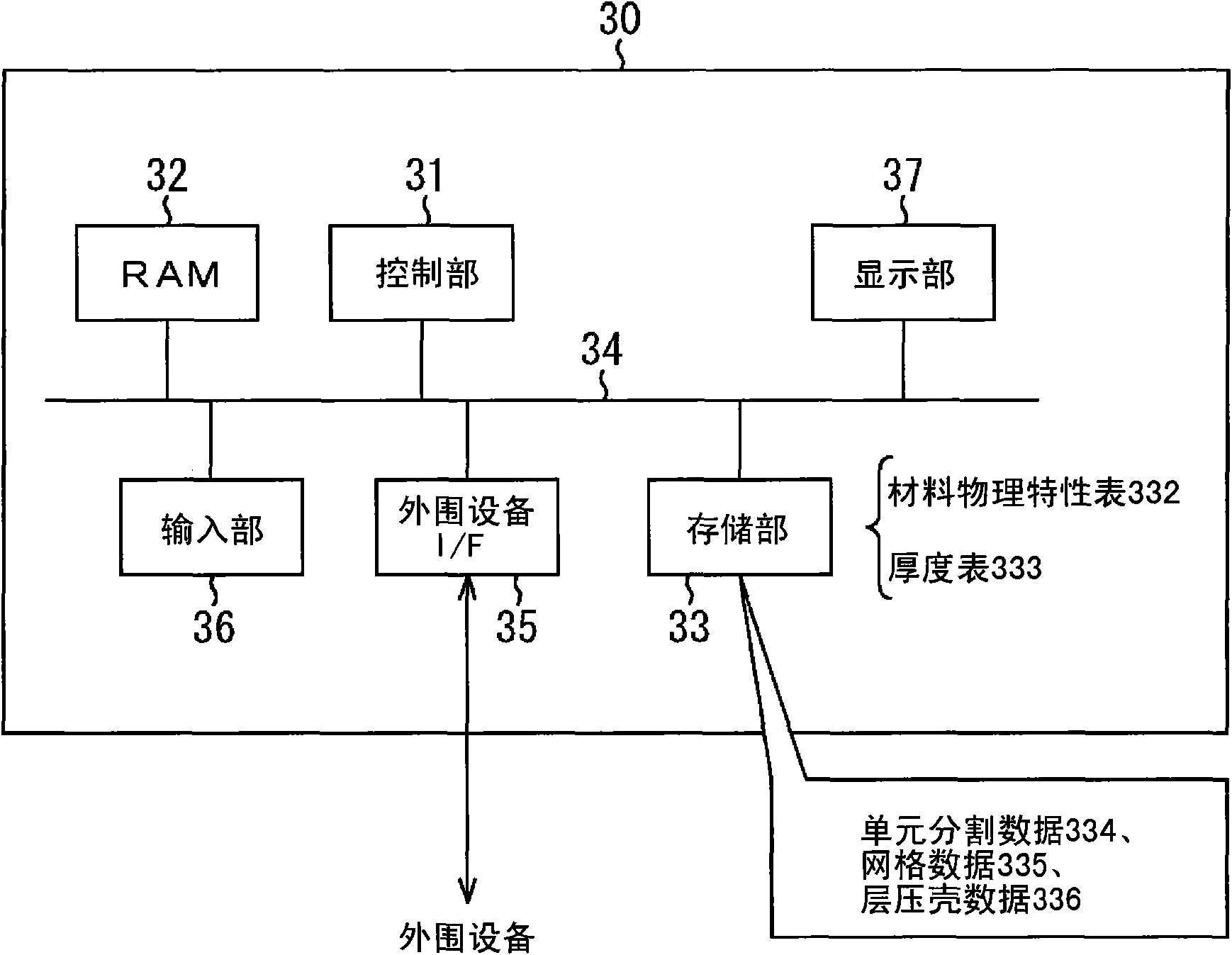

[0034] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. A structure analysis device according to an embodiment of the present invention is a device for performing structure analysis on a printed wiring board or the like. That is, the object to be analyzed by the structure analysis device (analyzed object) is a printed wiring board or the like.

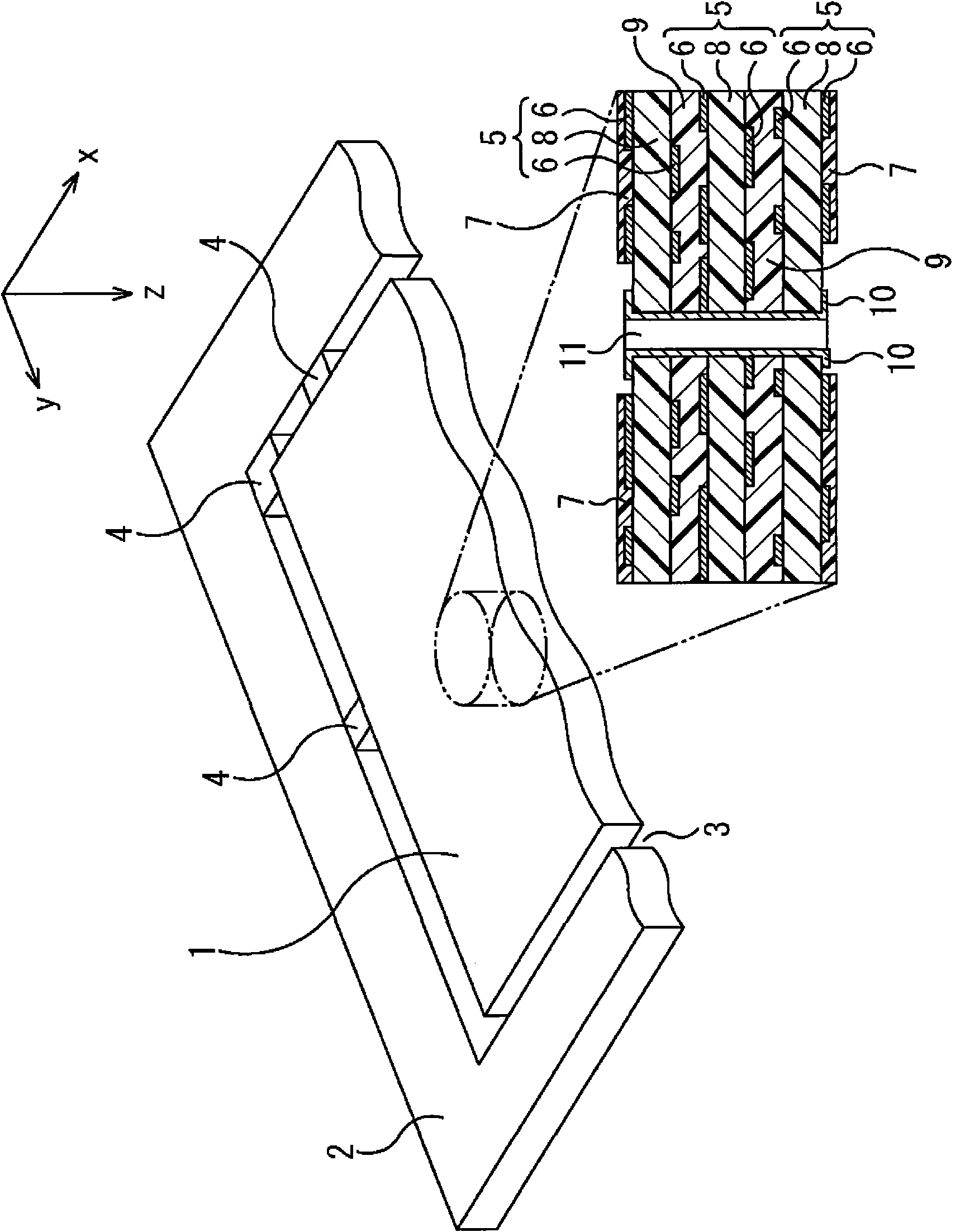

[0035] First, the analysis object will be described. figure 1 It is a diagram showing an example of an analysis object of the structure analysis device according to the embodiment of the present invention.

[0036] In this example, the object to be analyzed includes a printed circuit board 1 and a frame 2 surrounding the printed circuit board 1 . There is a separation groove 3 between the printed wiring board 1 and the frame 2 , and ribs 4 for connecting the printed wiring board 1 and the frame 2 are provided in multiple places in the separation groove 3 . By cutting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com