Exhaust valve

A technology of exhaust valve and exhaust hole, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of easy generation of impurities and dirt, poor exhaust performance of exhaust valve, increase of boiler and pipeline pressure, etc. Not easy to impurity and dirt, ensure normal work, improve the effect of exhaust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

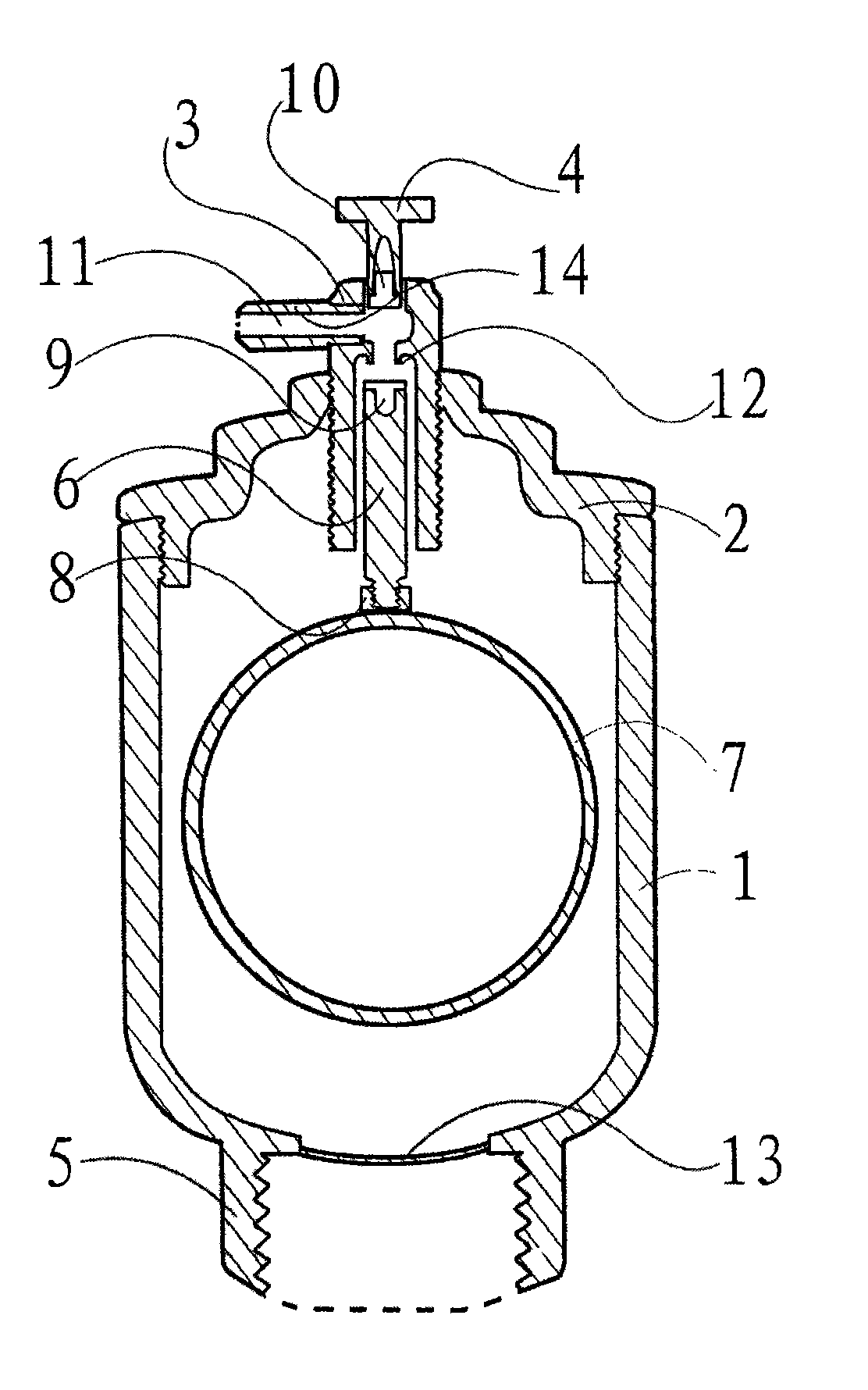

[0017] Such as figure 1 As shown, the internal thread of the upper part of the housing 1 is screwed to the external thread of the lower part of the valve cover 2. An internal threaded hole is provided in the middle of the valve cover 2 to be screwed to the valve core 3, and the valve core 3 is screwed to the exhaust nozzle 14. An exhaust hole 11 is provided inside the valve core 3 and the exhaust nozzle 14. The exhaust hole 11 at the lower end of the valve core 3 is movably installed into the floating rod 6; the exhaust hole 11 at the upper end of the valve core 3 is screwed with the manual screw 4, A silicone pad B10 is inserted into the lower part of the manual screw 4 to manually close the exhaust hole 11 to prevent the gas in the housing 1 from being discharged. An exhaust nozzle 14 is screwed on one side of the valve core 3 to discharge gas. A valve core inner port 12 is provided in the upper inner part of the exhaust hole 11 at the lower end of the valve core 3. The inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com