Extracted corn protein and production method thereof

A protein extraction technology, which is applied in the preparation method of peptides, chemical instruments and methods, plant peptides, etc., can solve the problems of increasing the cost of wastewater treatment, seriously polluting the water environment, and wasting available protein powder. Effects of solving pollution problems and reducing pressure on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

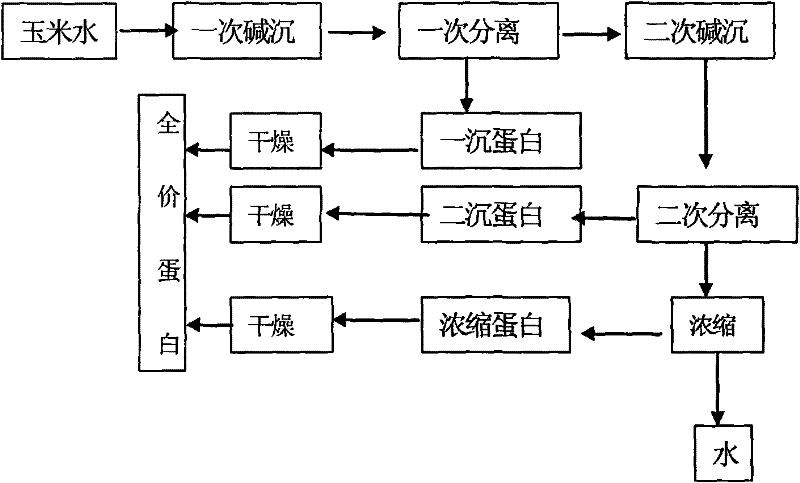

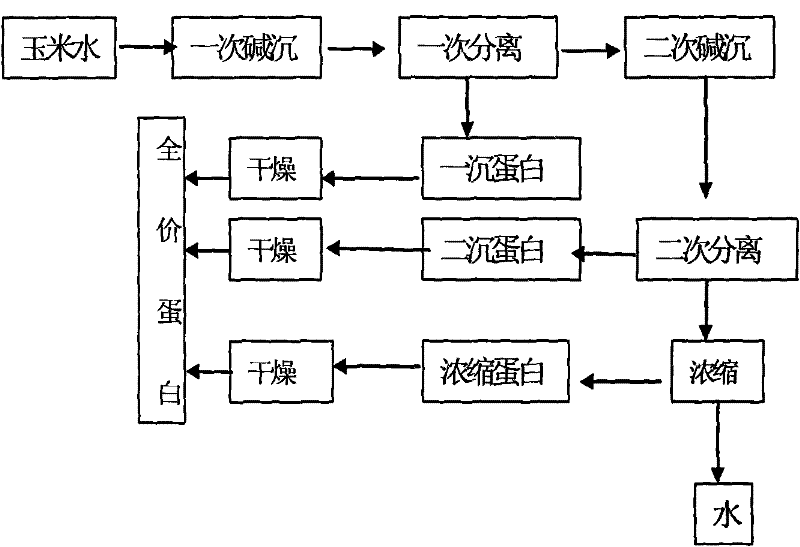

Method used

Image

Examples

Embodiment 1

[0015] (1) Primary precipitation: the Baume degree of corn soaking water stock solution is 9Be °, pH is 3.5; Regulate its pH with sodium hydroxide to be 6.5, stir evenly, utilize the difference of isoelectric point of various proteins to make part of the protein flocculate and precipitate first, Raise the temperature to 80°C, keep it warm for 30 minutes, and separate the solid and liquid once to obtain a precipitated protein (paste);

[0016] (2) Secondary precipitation: After the first settling, the Baume degree of the liquid is 5 Be °, and the pH is 6.5; the pH is adjusted to 8.5 with calcium hydroxide, stirred evenly, and placed at room temperature for 30 minutes, a large amount of calcium precipitated protein is precipitated, and the second settling at room temperature Secondary solid-liquid separation to obtain secondary precipitated protein (paste);

[0017] (3) Evaporation and concentration: the liquid after the secondary precipitation is concentrated in a three-effect ...

Embodiment 2

[0023] (1) Primary precipitation: the Baume degree of corn soaking water stock solution is 8.5Be°, pH is 4.0; use sodium hydroxide to adjust its pH to 6.3, stir evenly, use the different isoelectric points of various proteins to first make some proteins flocculate and precipitate , the temperature was raised to 80°C, and after 30 minutes of heat preservation, a solid-liquid separation was performed to obtain a precipitated protein (paste);

[0024] (2) Secondary precipitation: After the first settling, the Baume degree of the liquid is 4.5Be°, and the pH is 6.3; the pH is adjusted to 8.3 with calcium hydroxide, stirred evenly, and placed at room temperature for 30 minutes, a large amount of calcium precipitated protein is precipitated, and at room temperature Secondary solid-liquid separation to obtain secondary precipitated protein (paste);

[0025] (3) Evaporation and concentration: the liquid after the secondary precipitation is concentrated in a three-effect vacuum to obta...

Embodiment 3

[0031] (1) Primary precipitation: the Baume degree of corn soaking water stock solution is 8.0Be°, pH is 3.0; use sodium hydroxide to adjust its pH to 6.0, stir evenly, use the different isoelectric points of various proteins to first make some proteins flocculate and precipitate , the temperature was raised to 80°C, and after 30 minutes of heat preservation, a solid-liquid separation was performed to obtain a precipitated protein (paste);

[0032] (2) Secondary precipitation: After the first settling, the Baume degree of the liquid is 4Be °, and the pH is 6.0; the pH is adjusted to 8.0 with calcium hydroxide, stirred evenly, and placed at room temperature for 30 minutes, a large amount of calcium precipitated protein is precipitated, and the second precipitation at room temperature Secondary solid-liquid separation to obtain secondary precipitated protein (paste);

[0033] (3) Evaporation and concentration: the liquid after the secondary precipitation is concentrated in a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com