Centering device applicable to large hydraulic dismantling machine

A technology of centering device and disassembly machine, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of high price, low adjustment efficiency, screw damage, etc., and achieve the effects of convenient operation, simple operation, and fast advance and retreat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

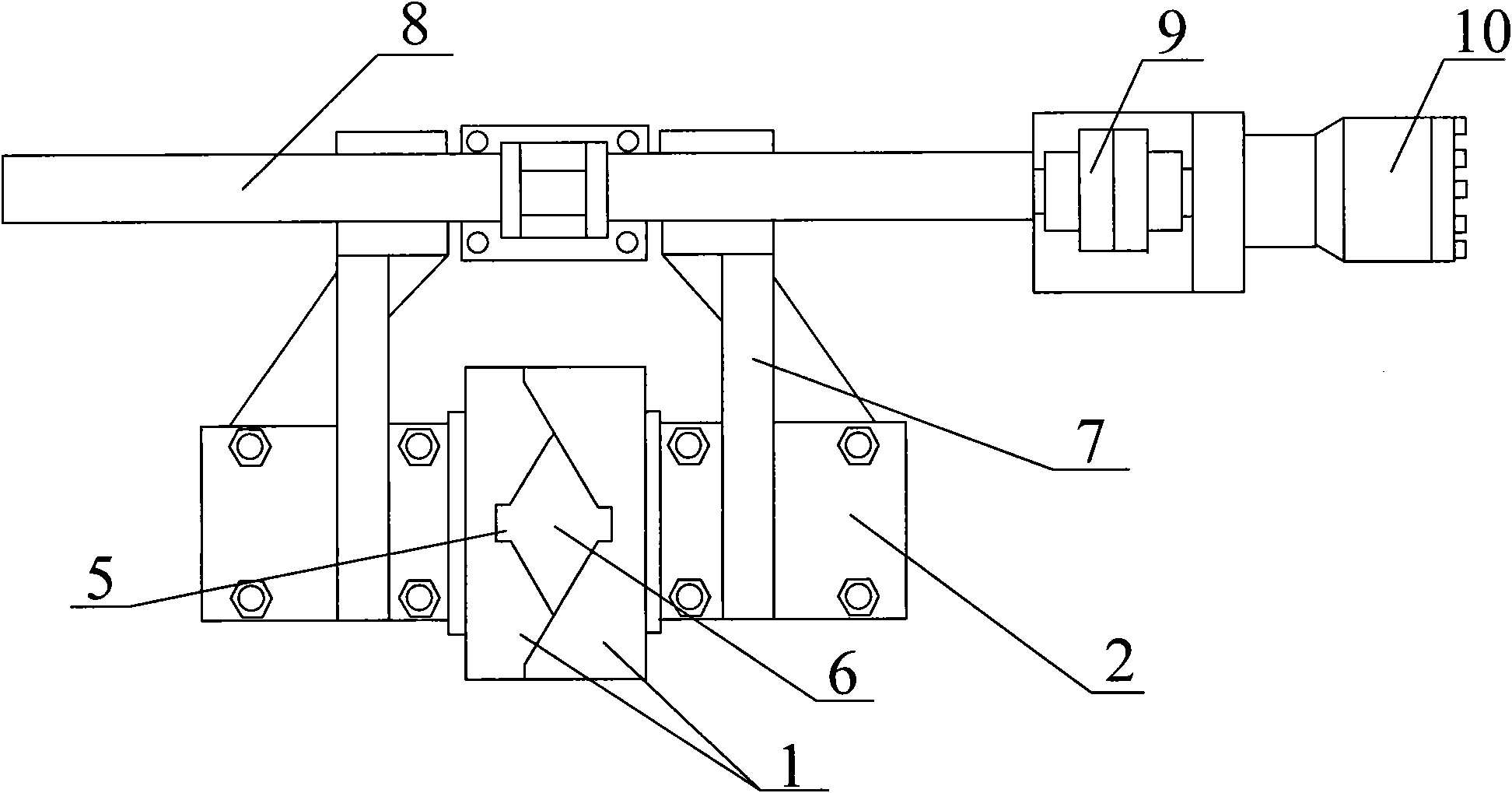

[0023] Such as figure 1 As shown, the centering device applied to a large hydraulic disassembly machine is mainly composed of a claw 1 and a fixing part 2 connected with the claw 1; the number of the claw 1 is two, and they are all installed in a horizontal direction; on the said fixture 2, a lead screw nut support 7 is also arranged, and the said lead screw nut support 7 is in the vertical direction; The threaded screw 8 is fixed on two screw nut supports 7; a shaft coupling 9 is also arranged at one end of the left and right threaded screws 8; the centering device also includes a hydraulic motor 10, and the hydraulic motor 10 is connected to the shaft coupling 9, and is on the same straight line as the left and right buckle screws 8 and the shaft coupling 9.

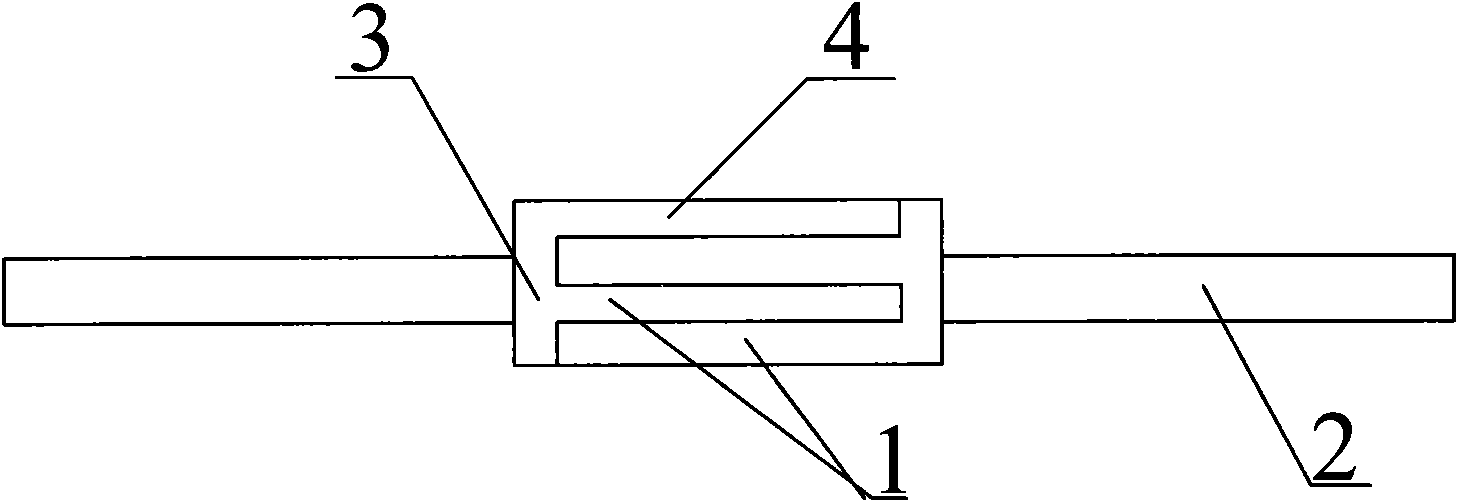

[0024] Such as figure 2 As shown, the claw 1 is composed of a base 3 and a plurality of protrusions 4 perpendicular to the base 3 arranged on the base 3, the protrusions 4 are parallel to each other, and the protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com