Preparation method of nuclear shell type CaCO3/SiO2 toothpaste abrasive

A core-shell type and abrasive technology, applied in dentistry, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as tooth wear, calcium carbonate abrasives and fluoride poor compatibility, and achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]Weigh 1g PSSS and dissolve it in 1000ml distilled water to prepare a PSSS solution with a concentration of 1g / L. At a stirring speed of 300 rev / min, 40 ml of sodium carbonate solution with a concentration of 0.5 mol / L was poured into the PSSS solution, and ammonia water was added to adjust the pH value of the solution to 10. Then, at a stirring speed of 300 rpm, 40 ml of calcium chloride solution with a concentration of 0.5 mol / L was added again; the solution was continuously stirred for 10 min, and then left to stand at room temperature for 48 h. Take out the precipitate, filter, use distilled water 3-5 times, and dry at 90-100°C for 1-2 hours to obtain spherical calcium carbonate particles with an average particle size of 13.5 μm.

[0028] Take by weighing above-mentioned spherical calcium carbonate particle 6g, join in the dehydrated alcohol of 80ml, and add concentration simultaneously and be 5% dodecyltrimethylammonium bromide (CTAB) aqueous solution 20ml, ultrasoni...

Embodiment 2

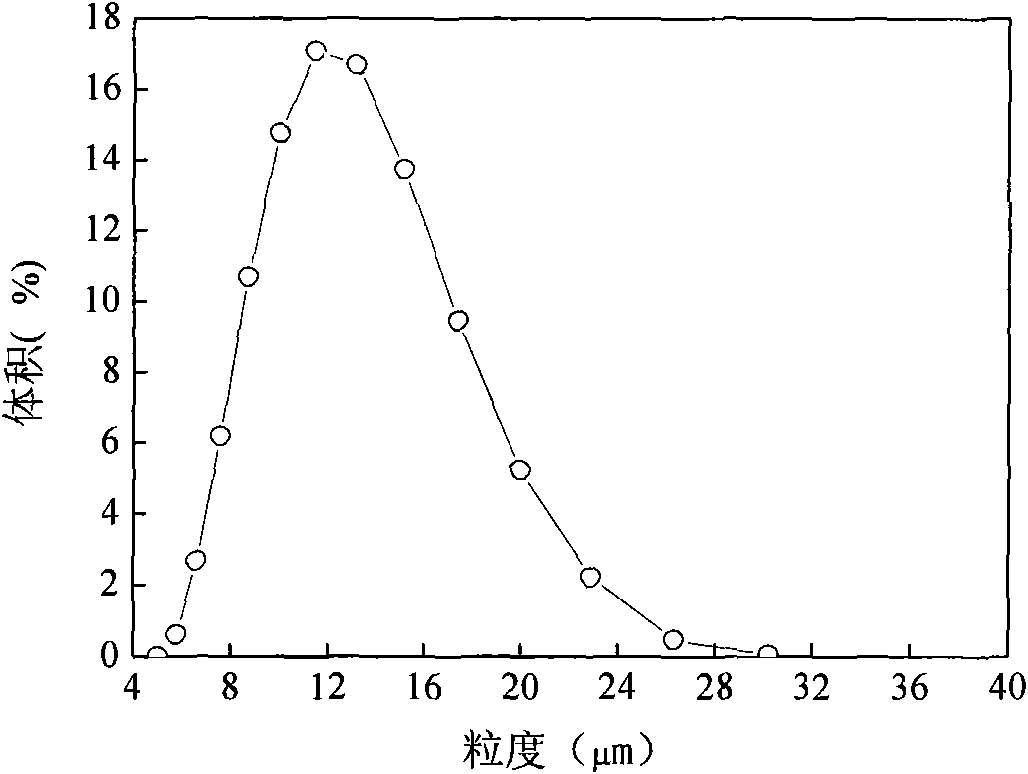

[0030] Weigh 2g PSSS and dissolve it in 1000ml distilled water to prepare a PSSS solution with a concentration of 2g / L. At a stirring speed of 500 rev / min, 25 ml of sodium carbonate solution with a concentration of 0.5 mol / L was poured into the PSSS solution, and ammonia water was added to adjust the pH value of the solution to 10. Then, at a stirring speed of 500 rpm, 25 ml of calcium chloride solution with a concentration of 0.5 mol / L was added again; the solution was continuously stirred for 10 min, and then left to stand at room temperature for 24 h. Take out the precipitate, filter, use distilled water 3 to 5 times, and dry at 90 to 100°C for 1 to 2 hours to obtain spherical calcium carbonate particles with an average particle size of 11.2 μm ( figure 1 ).

[0031] Take by weighing above-mentioned spherical calcium carbonate particle 2g, join in the dehydrated alcohol of 30ml, and add concentration simultaneously and be 5% dodecyltrimethylammonium bromide (CTAB) aqueous ...

Embodiment 3

[0033] Weigh 4g PSSS and dissolve it in 1000ml distilled water to prepare a PSSS solution with a concentration of 4g / L. At a stirring speed of 200 rpm, pour 30 ml of a sodium carbonate solution with a concentration of 0.5 mol / L into the PSSS solution, and add ammonia water to adjust the pH value of the solution to 10. Then, at a stirring speed of 200 rpm, 30 ml of calcium chloride solution with a concentration of 0.5 mol / L was added again; the solution was continuously stirred for 10 min, and then left to stand at room temperature for 24 h. Take out the precipitate, filter, use distilled water 3-5 times, and dry at 90-100°C for 1-2 hours to obtain spherical calcium carbonate particles with an average particle size of 5.5 μm.

[0034] Take by weighing above-mentioned spherical calcium carbonate particle 2g, join in the dehydrated alcohol of 30ml, and add concentration simultaneously and be 5% dodecyltrimethylammonium bromide (CTAB) aqueous solution 10ml, ultrasonic dispersion 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com