Three-dimensional heat source

A heat source, three-dimensional technology, applied in the direction of heating elements, heating element materials, ohmic resistance heating parts, etc., can solve the problems of uneven radiation, low strength of carbon fiber paper, short radiation distance, etc., and achieve high electrothermal conversion efficiency and uniform thickness And resistance, heat exchange speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The three-dimensional heat source of the present invention will be described in detail below with reference to the accompanying drawings.

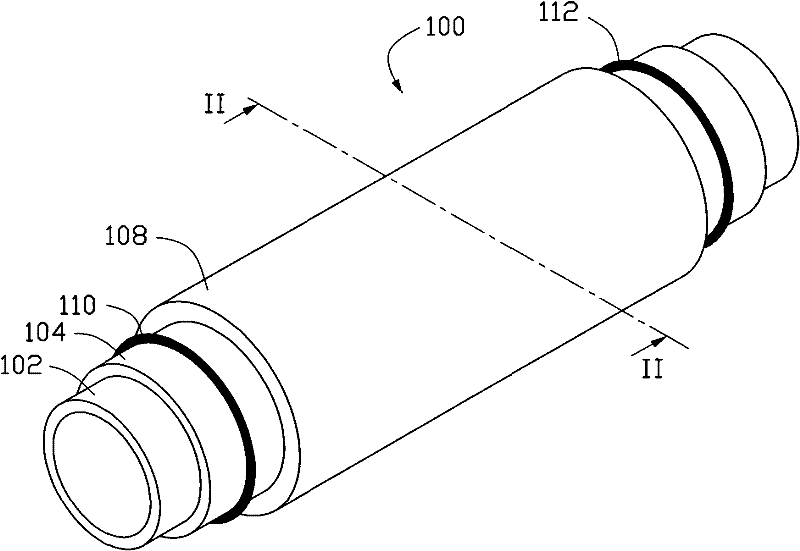

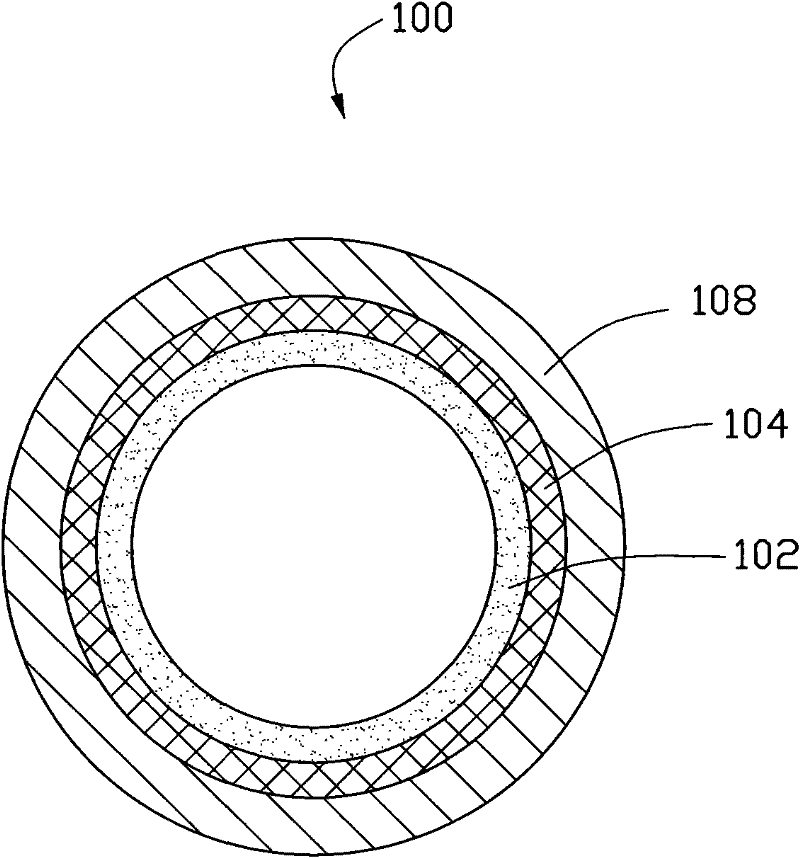

[0018] see figure 1 and figure 2 , to provide a three-dimensional heat source 100 according to the first embodiment of the present invention. The three-dimensional heat source 100 includes a hollow three-dimensional support structure 102 , a heating element 104 , a first electrode 110 and a second electrode 112 . The heating element 104 is disposed on the outer surface of the hollow three-dimensional support structure 102 . The first electrode 110 and the second electrode 112 are respectively electrically connected to the heating element 104 for electrically connecting the heating element 104 to a power source.

[0019] The hollow three-dimensional support structure 102 is used to support the heating element 104, so that the heating element 104 forms a three-dimensional structure, and the three-dimensional structure defines a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com