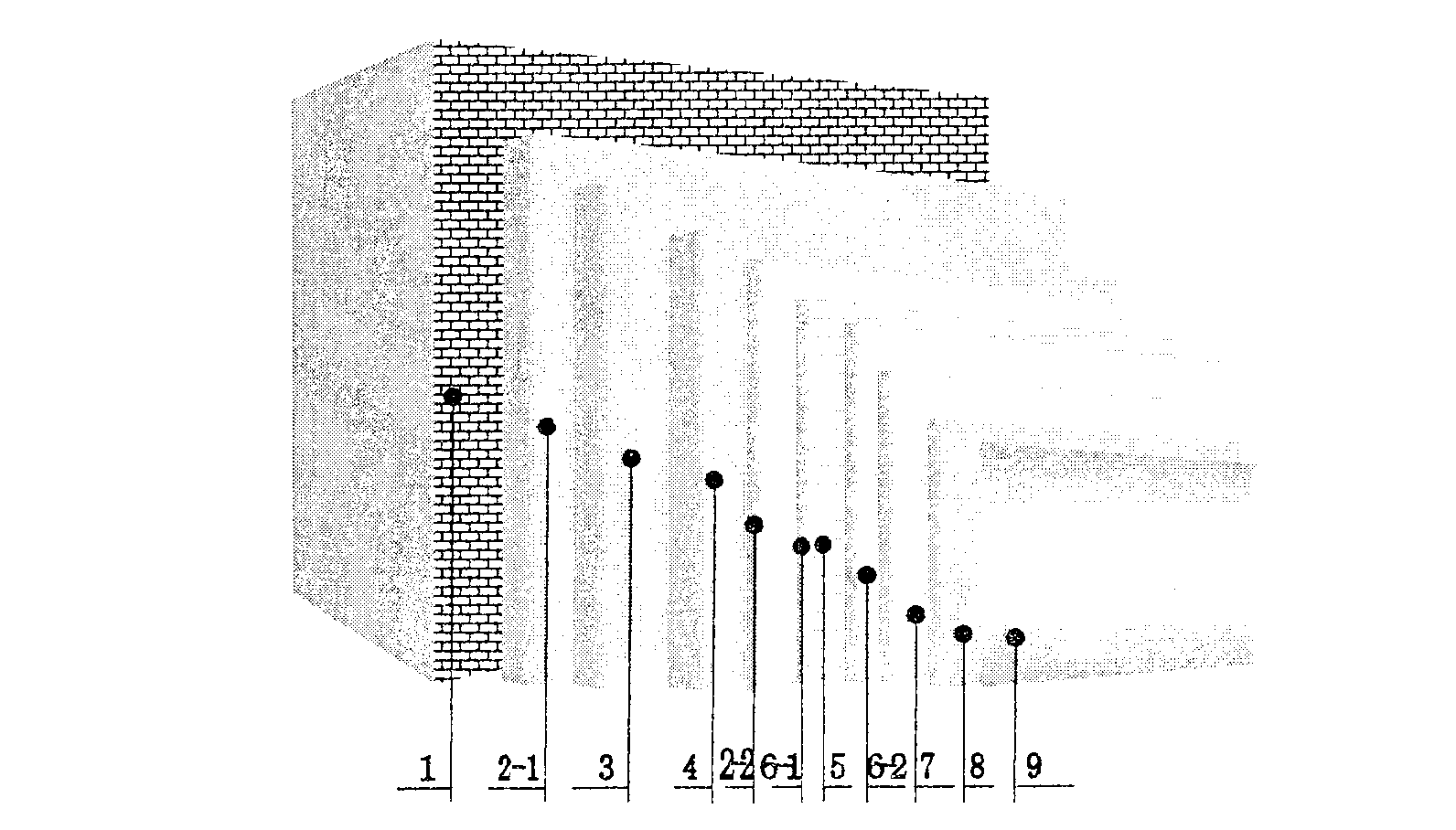

Outer heat-insulation system of outer wall

A technology of external thermal insulation and thermal insulation putty for external walls, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of loss of decoration and protection, falling off of external thermal insulation system, decrease of bond strength of polystyrene board, etc., and achieve excellent thermal insulation effect, high solar heat reflectance, and low thermal conductivity of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the examples, but not limited thereto.

[0023] Various raw materials used in the examples are commercially available industrial products. The tools and equipment used to practice the invention are those commonly used in the paint and construction industries.

[0024] Embodiment Carry out external wall thermal insulation to a civil building with the external wall thermal insulation system of the present invention

[0025] (1) To prepare raw materials, the percentages in the following raw material dosages are all percentages by weight

[0026] ① Preparation of interface agent: 30% of acrylic emulsion, 0.5% of cellulose, 0.05% of silicone antifoaming agent, 0.1% of heterocyclic preservative, and the balance is water, weigh the raw materials and mix them evenly, and set aside;

[0027] The grade of the acrylic emulsion is SN-01, which is produced by CNOOC Changzhou Paint Chemical Research...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com