Method for manufacturing wearable coating composite board

A technology of wear-resistant coating and manufacturing method, which is applied in the field of manufacturing of wear-resistant coated composite boards, can solve problems such as poor wear resistance, impact resistance and high temperature resistance, uneven product performance, and affecting production progress. Achieve high corrosion resistance and high temperature red hardness, wide practicability and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

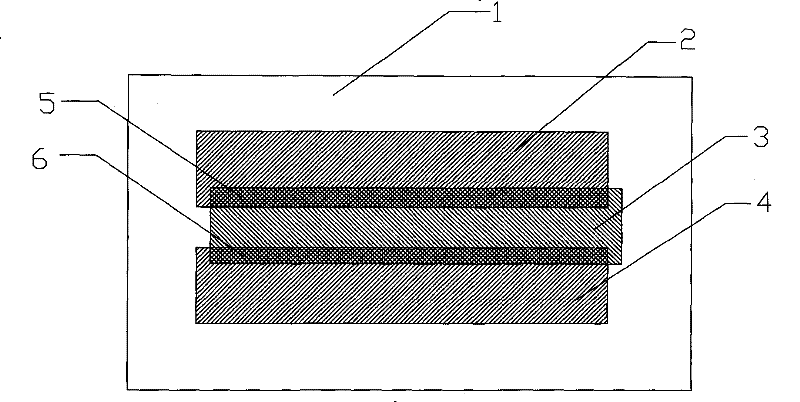

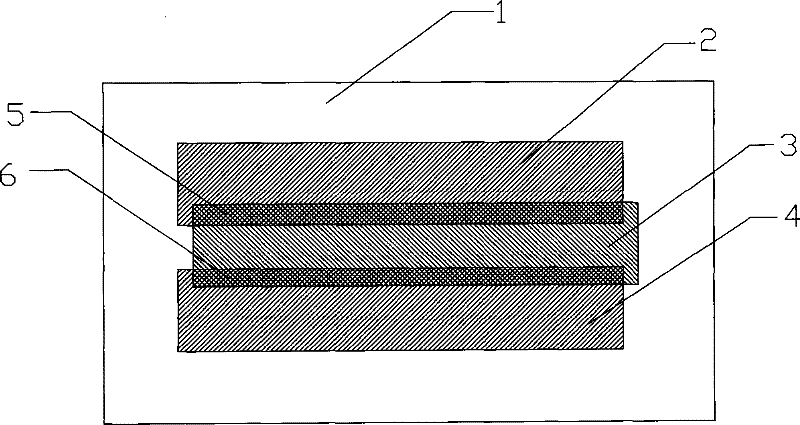

[0018] Put the base material 1 on a clean platform and put it upright and firm, and press it firmly with a wide pressure plate at a distance of no more than 300mm around the base material 1. The wear-resistant coating of high chromium cast iron is selected with a chromium content of more than 12 % of high chromium cast iron, the flux used is HJ130 which has been dried, and after checking the sensitivity and reliability of each start switch, adjustment knob, and operating part of the equipment, the coating is carried out by segmental method. High-chromium cast iron 2, and then surfacing the same strip-shaped high-chromium cast iron 4 to the base material at intervals, and then surfacing the same strip-shaped high-chromium cast iron 3 in parallel to the interval, and there is a 5mm gap with the original coating At junctions 5 and 6, the entire base material is surfacing in turn.

[0019] The coating thickness is 2mm, the wire diameter is ∮3.2mm, the voltage is 38V, the current i...

specific Embodiment 2

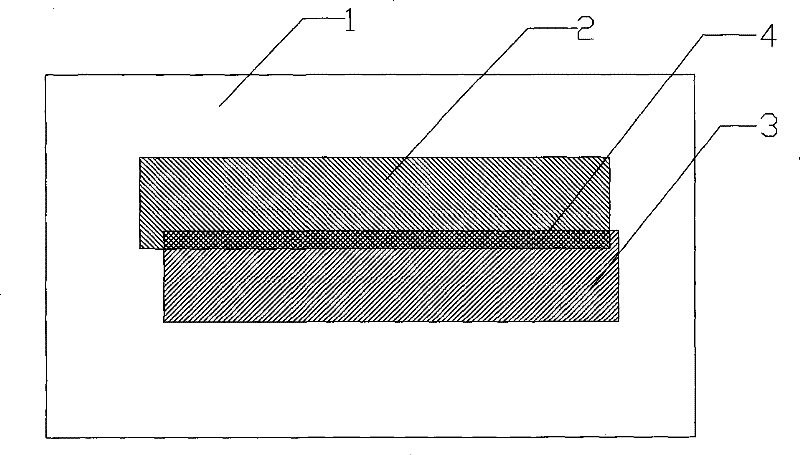

[0020] Put the base material 1 on a clean platform and put it upright and firm, and press it firmly with a wide pressure plate at a distance of no more than 300mm around the base material 1. The wear-resistant coating of high chromium cast iron is selected with a chromium content of more than 12 % high chromium cast iron, the flux is dried HJ130, after checking the sensitivity and reliability of each start switch, adjustment knob, and operating part of the equipment, use the lamination method to coat. High-chromium cast iron 2, and then surfacing welding of the same strip-shaped high-chromium cast iron 3 on the substrate, and a 5mm junction 4 with the original high-chromium cast iron coating, and surfacing and welding the entire substrate in turn.

[0021] The coating thickness is 4mm, the wire diameter is ∮3.2mm, the voltage is 40V, the current is 450A, the powder feeding ratio is 1:4, and the welding speed is 0.4m / min. The slag must be removed before surfacing of adjacent co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com