Integration hydraulic brake system of wind generating set

A technology for wind turbines and integrated hydraulics, which is applied in the control of wind turbines, wind turbines, and wind power generation. It can solve the problems of complex structure, inconvenient operation, poor safety and reliability, etc. Small, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

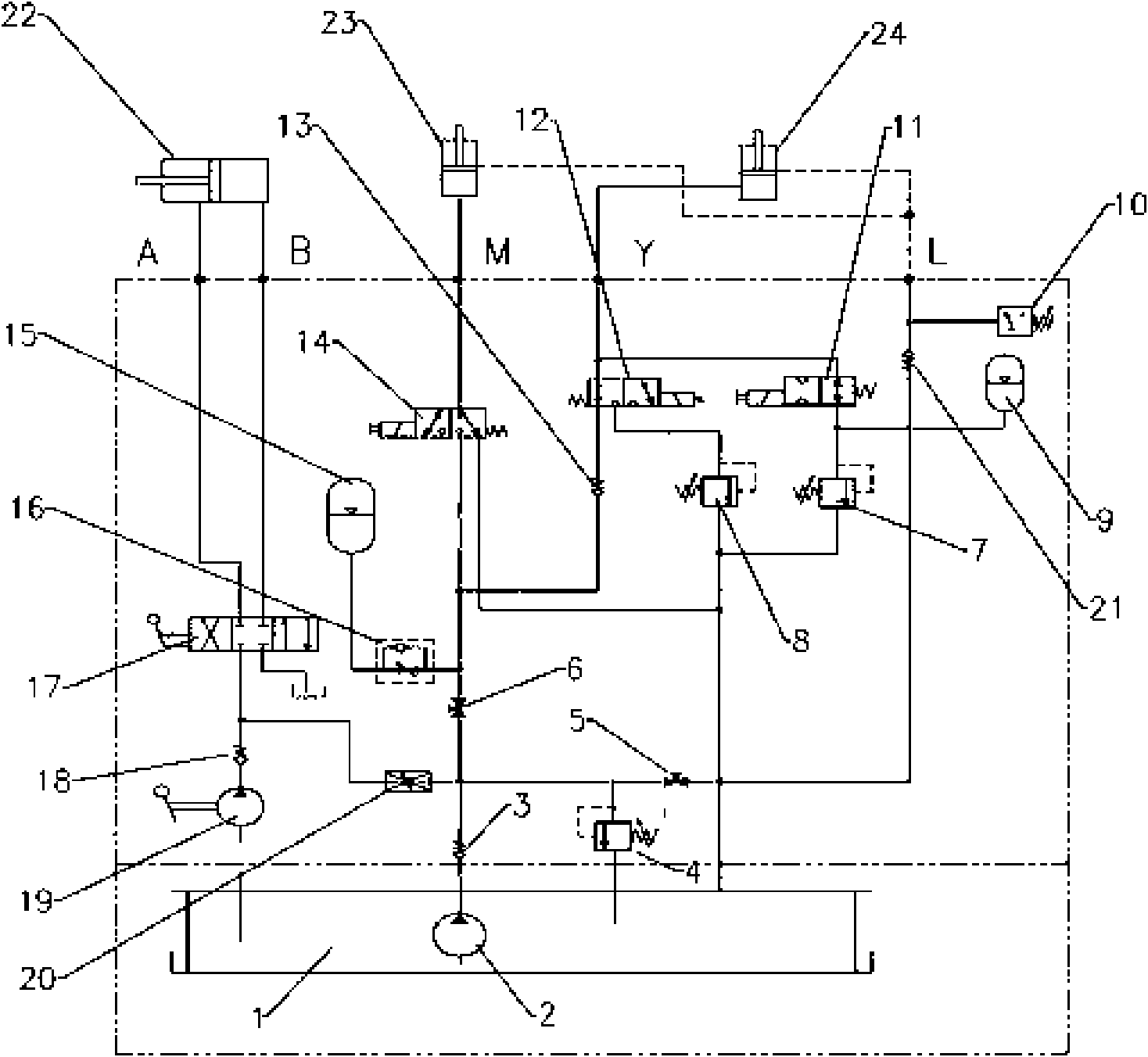

[0014] refer to figure 1 , this embodiment includes a main bearing brake cylinder 23 with a spindle brake function, a yaw brake cylinder 24 with a yaw brake function, a lock cylinder 22 with a lock brake function, and an integrated hydraulic brake moving device ( figure 1 The part of the integrated hydraulic braking device is inside the line drawn at the midpoint), the main bearing brake cylinder 23 is connected to the electromagnetic reversing valve III14 with manual operation function through the M oil port of the integrated hydraulic braking device, and the electromagnetic reversing valve III14 passes through the cut-off Valve II 6 and one-way valve I 3 are connected to the electric hydraulic pump 2, and the accumulator II 15 is connected between the electromagnetic reversing valve III 14 and the shut-off valve II 6 through the one-way throttle valve 16, and the oil out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com