Nano conductive adhesive and preparation method thereof

A nano-conductive and conductive adhesive technology, applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of complex reaction conditions, low output, long reaction time, etc., and achieve simple preparation, uniform particle size, and conductive good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

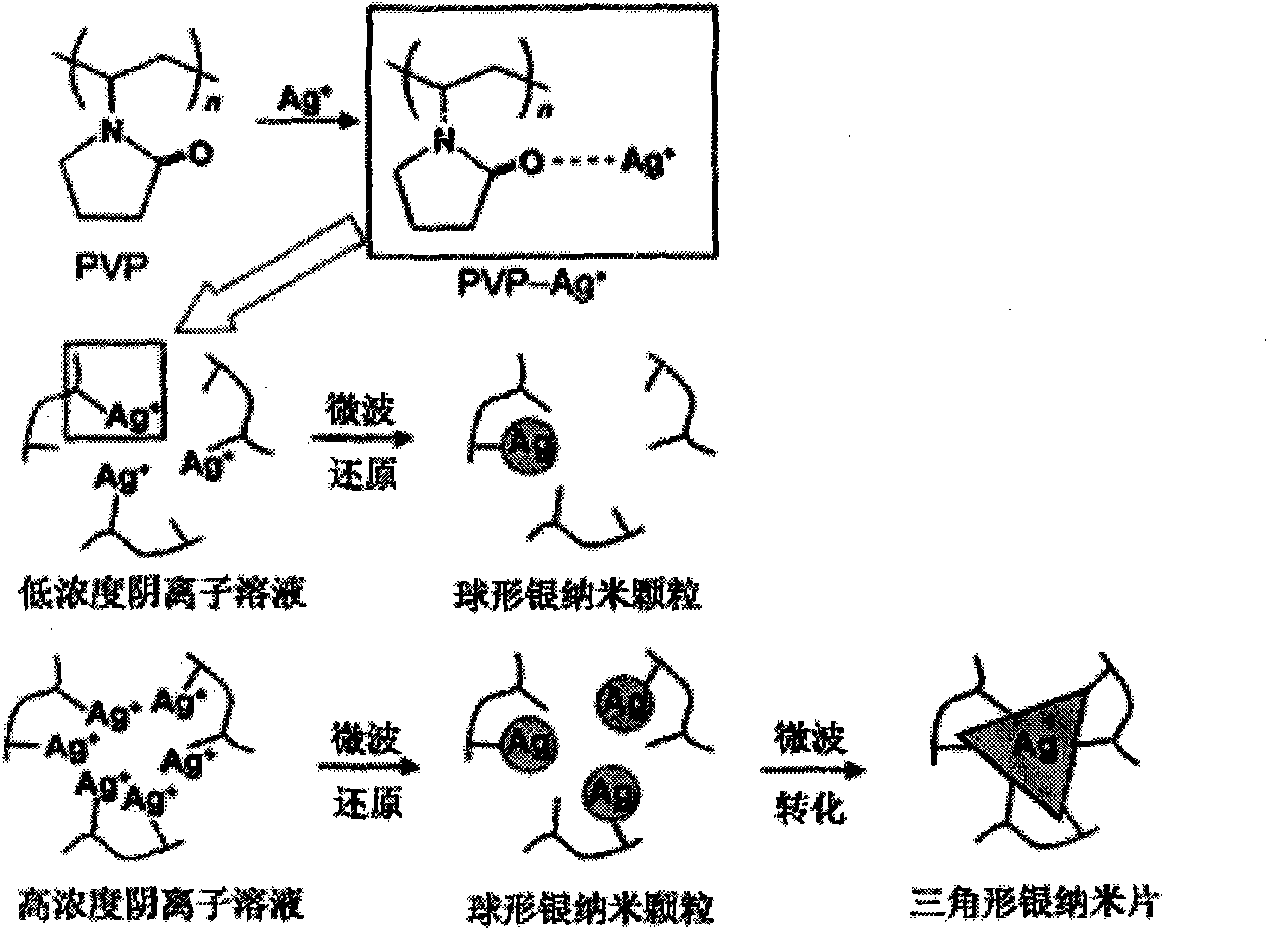

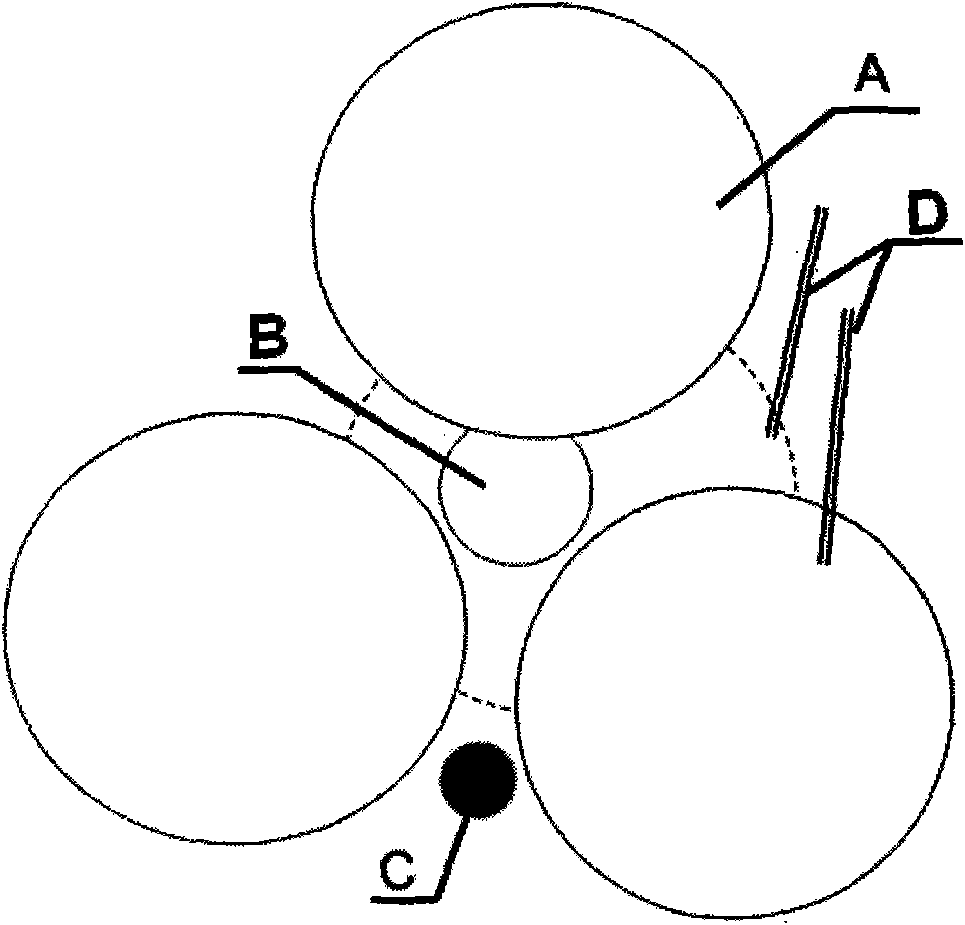

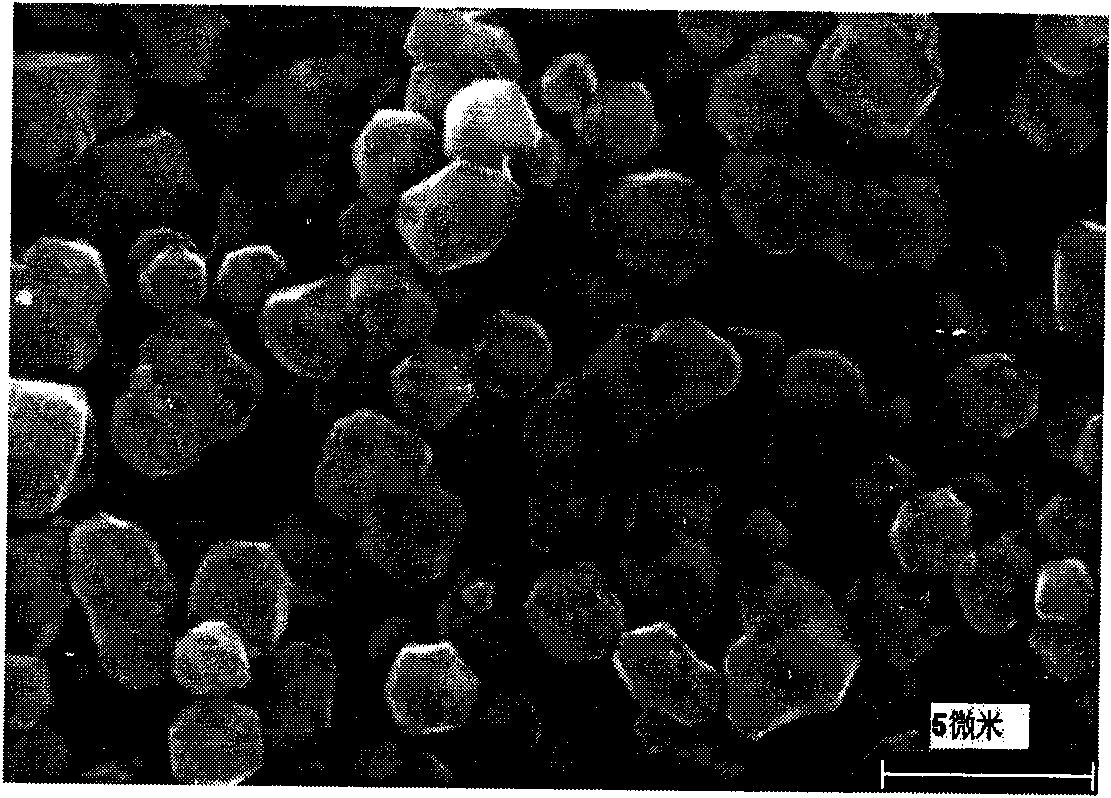

[0051] The present invention also provides a preparation method of the above-mentioned nano-conductive adhesive. The preparation method is to control the reaction conditions through a microwave method to selectively prepare micron-sized, sub-micron-sized and nano-sized conductive particles. Mix silver powders and wires of different sizes in a specific particle size range and ratio to obtain an optimal compact packing. The above-mentioned conductive particles and polymer materials are mixed according to a predetermined ratio through a mixer, and a conductive adhesive with high conductivity and high rheology can be prepared.

[0052] The preparation of the present invention is divided into two steps:

[0053] (1) Prepare silver conductive particles by microwave heating.

[0054] (2) Select specific micron to nanometer-scale silver powder and silver wire particle size and proportion, and mix the above-mentioned conductive particles with polymer materials, solvents, curing agents...

Embodiment 1

[0110] The above-mentioned conductive particles of silver prepared by microwave heating are mixed in the following proportions:

[0111] Micron silver powder (A): submicron silver powder (B): nano silver powder (C): nano silver wire (D) = 30:6:1:1; then mixed with epoxy resin, solvent, curing agent, etc. to obtain conductive Glue, the mass ratio of each substance is:

[0112] Mixed conductive particles: 70%

[0113] Epoxy: 25%

[0114] Solvent: 2.5%

[0115] Curing agent: 2.5%.

[0116] The obtained conductive adhesive has more excellent conductivity than common conductive adhesives.

Embodiment 2

[0118] The above-mentioned conductive particles of silver prepared by microwave heating are mixed in the following proportions:

[0119] Micron silver powder (A): submicron silver powder (B): nano silver powder (C): nano silver wire (D) = 30:6:1:1; then mixed with epoxy resin, solvent, curing agent, etc. to obtain conductive Glue, the mass ratio of each substance is:

[0120] Mixed conductive particles: 65%

[0121] Epoxy resin: 30%

[0122] Solvent: 2%

[0123] Curing agent: 3%.

[0124] The obtained conductive adhesive has good mechanical properties in addition to excellent electrical conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com