Method for synthesizing diphenyl carbonate through ester exchange reaction of dimethyl carbonate and phenylethyl acetate

A technology of dimethyl carbonate and transesterification, which is applied in the field of synthesizing diphenyl carbonate by transesterification of dimethyl carbonate and phenyl acetate, can solve the problems of low catalyst activity, unstable performance and the like, and achieves high catalyst activity, The effect of stable performance, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

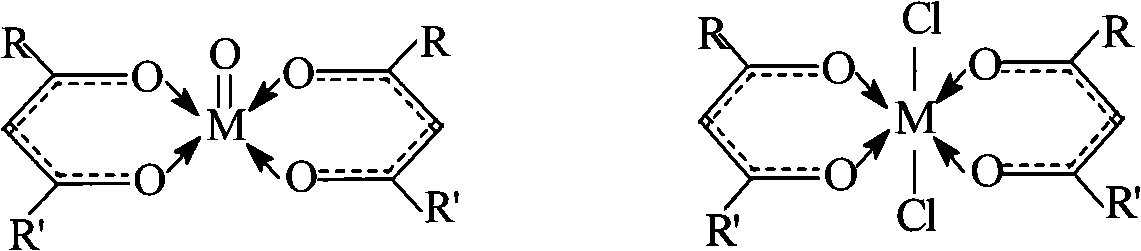

Method used

Image

Examples

Embodiment 1

[0020] Weigh 80.0 grams of phenyl acetate (about 0.58mol), 53.0 grams of dimethyl carbonate (about 0.58mol), and 1.2 grams of titanyl acetylacetonate (about 0.0055mol) into a 250ml autoclave with an intelligent constant temperature controller. Seal with fasteners, and then use nitrogen to confirm the airtightness of the high-pressure airtight reactor. Under normal pressure, stir and heat up to keep the reaction temperature between 150 ° C. After 4 hours of reaction, stop heating. Stir and cool down to room temperature naturally, open the reaction kettle, discharge the liquid material in the kettle, and analyze the liquid material with a gas chromatograph. The conversion rate of dimethyl carbonate is 30.0%, and the selectivity of the catalyst to methyl phenyl carbonate (MPC) and diphenyl carbonate (DPC) is 65.0% and 25.0%, respectively.

Embodiment 2

[0022] Weigh 110.0 grams of phenyl acetate (about 0.80 mol), 36.0 grams of dimethyl carbonate (about 0.40 mol), and 1.5 grams of titanium acetylacetonate (about 0.006 mol) into a 250 ml high-pressure reactor with an intelligent constant temperature controller. Seal with fasteners, and then use nitrogen to confirm the airtightness of the high-pressure airtight reactor. Under normal pressure, stir and heat up to keep the reaction temperature between 175 ° C. After 4.5 hours, the reaction is over and the heating is stopped. Stir and cool down to room temperature naturally, open the reaction kettle, discharge the liquid material in the kettle, and analyze the liquid material with a gas chromatograph. The conversion rate of dimethyl carbonate is 74.0%, and the selectivity of the catalyst to methyl phenyl carbonate (MPC) and diphenyl carbonate (DPC) is 58.0% and 38.0% respectively.

Embodiment 3

[0024] Weigh 110.0 grams of phenyl acetate (about 0.80 mol), 20.0 grams of dimethyl carbonate (about 0.22 mol), and 1.2 grams of titanyl acetylacetonate (about 0.0055 mol) into a 250 ml high-pressure reactor with an intelligent thermostat controller, Seal it with fasteners, and then use nitrogen to confirm the airtightness of the high-pressure airtight reactor. Under normal pressure, stir and heat up to keep the reaction temperature between 180 ° C. After 5 hours of reaction, stop heating. Stir and cool down to room temperature naturally, open the reaction kettle, discharge the liquid material in the kettle, and analyze the liquid material with a gas chromatograph. The conversion rate of dimethyl carbonate was 80.0%, and the selectivity of the catalyst to methylphenyl carbonate (MPC) and diphenyl carbonate (DPC) were 60.0% and 38.0%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com