Composite packing material and manufacturing method thereof

A composite packaging material and a production method technology, applied in the field of composite packaging materials of pearl cotton composite bubble cloth, can solve the problems of insufficient cushioning performance, insufficient appearance, etc., to improve the cushioning performance, enhance the appearance and cushioning performance, and ensure the safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

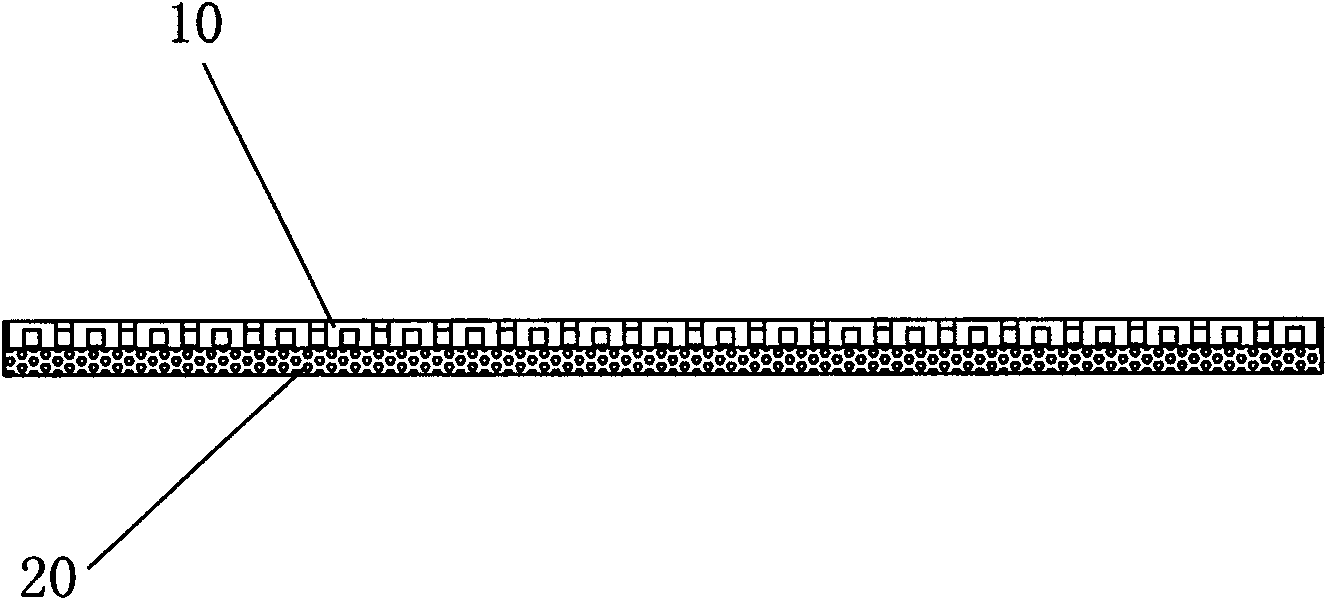

[0025] refer to Figure 1 to Figure 2 , the present invention is implemented like this:

[0026] A composite packaging material, comprising a matrix, the matrix is pearl cotton 20, and an air bubble cloth 10 is adhered to the outer side of the pearl cotton 20, and the air bubble cloth 10 and the pearl cotton 20 are melted on a high-temperature surface and then extruded together Adhesion.

[0027] The preparation method of above-mentioned composite packaging material comprises the following steps:

[0028] 1. First adjust the temperature of the heating oil inside the laminating machine. The oil temperature adjustment range is 120-170°C. The inside of the laminating machine is heating oil. By changing the load resistance, adjust the current of the heating laminating machine to control the oil temperature;

[0029] 2. By controlling the oil temperature and then controlling the temperature of the roller between 110°C and 165°C, pass the pearl cotton and bubble cloth through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com