Organic-inorganic compound mesoporous membrane and preparation method and application thereof

A composite mesoporous membrane and inorganic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor membrane flexibility, easy cracking, and high cost of porous alumina membranes, and achieve good flexibility, Good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

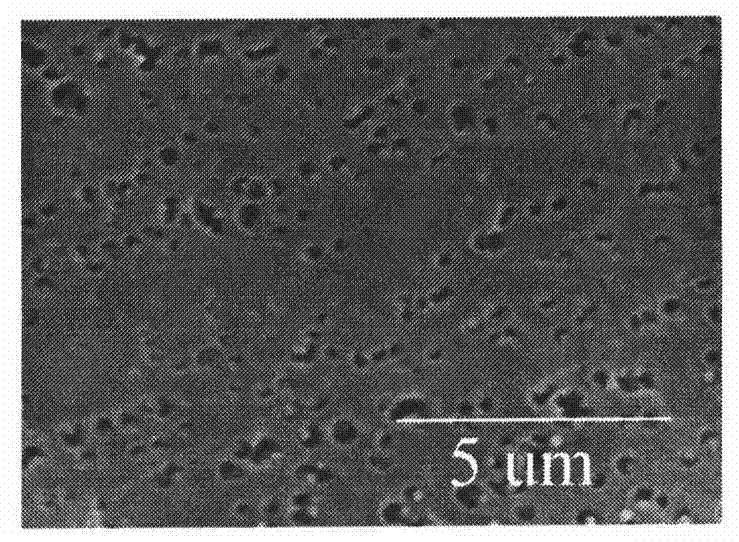

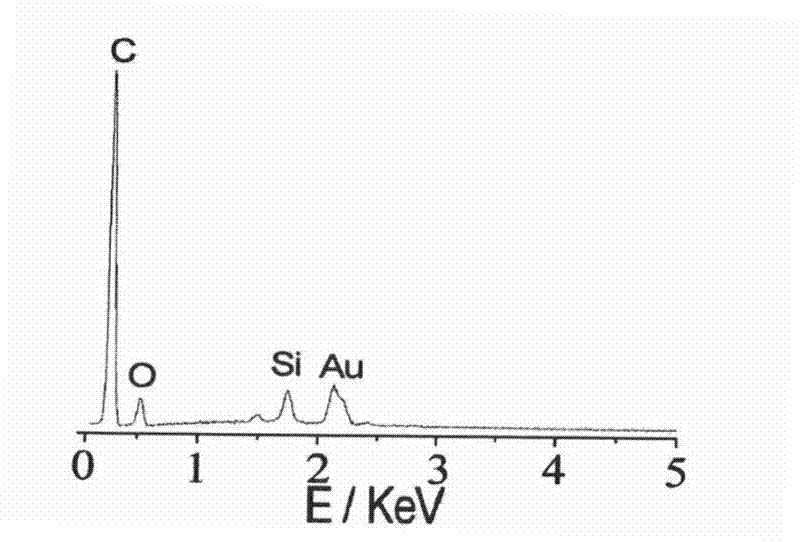

[0033] Preparation of organic-inorganic composite mesoporous membrane assembled with mesoporous materials with a pore diameter of 3.0 nm

[0034] Mix 7.68g of absolute ethanol, 11.57g of tetraethyl orthosilicate and 1ml of hydrochloric acid (2.8mmol / L), stir slowly and evenly, condense and reflux for 90min in a water bath at 60°C; then add 15g of absolute ethanol, 1.52 g cetyltrimethylammonium bromide (CTAB), 4ml of hydrochloric acid (55mmol / L) after the mixed solution, stirring reaction at room temperature 25 ℃ for 30min, cooled to room temperature 25 ℃ to obtain the precursor containing CTAB liquid. Using a suction filter pump (produced by Shanghai Mosu Scientific Equipment Co., Ltd., HPD-25 type oil-free suction filter pump) and a standing suction filter device (1000ml suction filter bottle) in the laboratory, the precursor solution of 6ml (containing CTAB) was divided into three times ( 2ml each time) was filtered through a porous polycarbonate membrane (produced by Whatm...

Embodiment 2

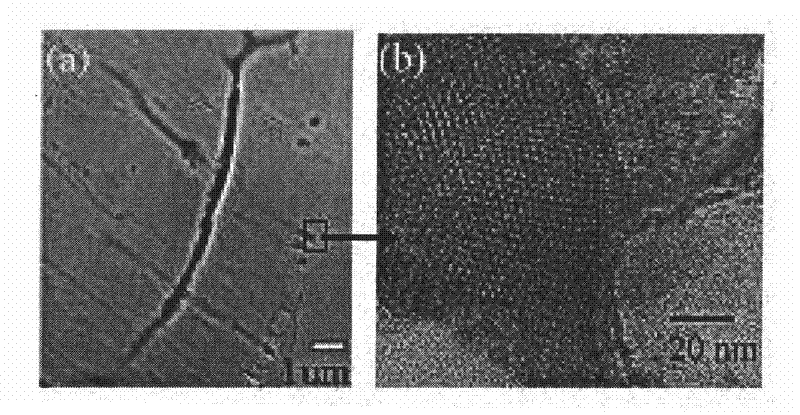

[0042] Preparation of organic-inorganic composite mesoporous membrane assembled with mesoporous materials with a pore diameter of 8.0 nm

[0043] 15g of absolute ethanol, 0.10g of hydrochloric acid (12mol / L) and 2.0g of deionized water were mixed uniformly and placed in a three-necked flask, then, under slow stirring, 1.0g of surfactant P123 was added to the mixed solution until P123 was completely dissolved, and the three-necked flask containing the mixed solution was placed in an oil bath, and at a temperature of 60°C, after slowly stirring for 1 h, 2.13 g of tetraethyl orthosilicate was gradually added dropwise, and at 60 ℃ oil bath temperature for 12h with stirring and aging, and then cooled to room temperature to obtain the precursor solution containing P123. Using a suction filtration pump (manufactured by Shanghai Mosu Scientific Equipment Co., Ltd., HPD-25 oil-free suction filtration pump) and a standing suction filtration device (1000 ml suction filtration bottle) in ...

Embodiment 3

[0051] The rhodamine B aqueous solution of 0.04mg / ml and the aqueous solution of 0.04mg / ml horseradish peroxidase were respectively placed in as attached Figure 7-8 Molecular transfer device shown. Investigation of rhodamine B dye molecules (molecular size3.0nm) in organic-inorganic composite mesoporous materials assembled with 3.0nm pore diameter mesoporous materials by ultraviolet-visible spectroscopy Size-selective transfer on membranes.

[0052] by attaching Figure 7 It can be observed that the rhodamine B dye molecule can be transferred through the membrane because its molecular size is smaller than the mesoporous aperture of the mesoporous material in the organic-inorganic composite mesoporous membrane;

[0053] by attaching Figure 8 It was observed that the molecular size of horseradish peroxidase was larger than the mesoporous pore diameter of the mesoporous material in the organic-inorganic composite mesoporous membrane, so the molecule could not be transferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com