Multilevel telescopic cylindrical type nozzle color mixing mechanism

A cylinder and nozzle technology is applied in the field of multi-stage cylinder-type nozzle color mixing mechanism, which can solve the problems of reduced efficiency, inaccurate measurement, inaccurate control of product accuracy, etc., and achieve accurate control of product accuracy, easy temperature control, and color mixing effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

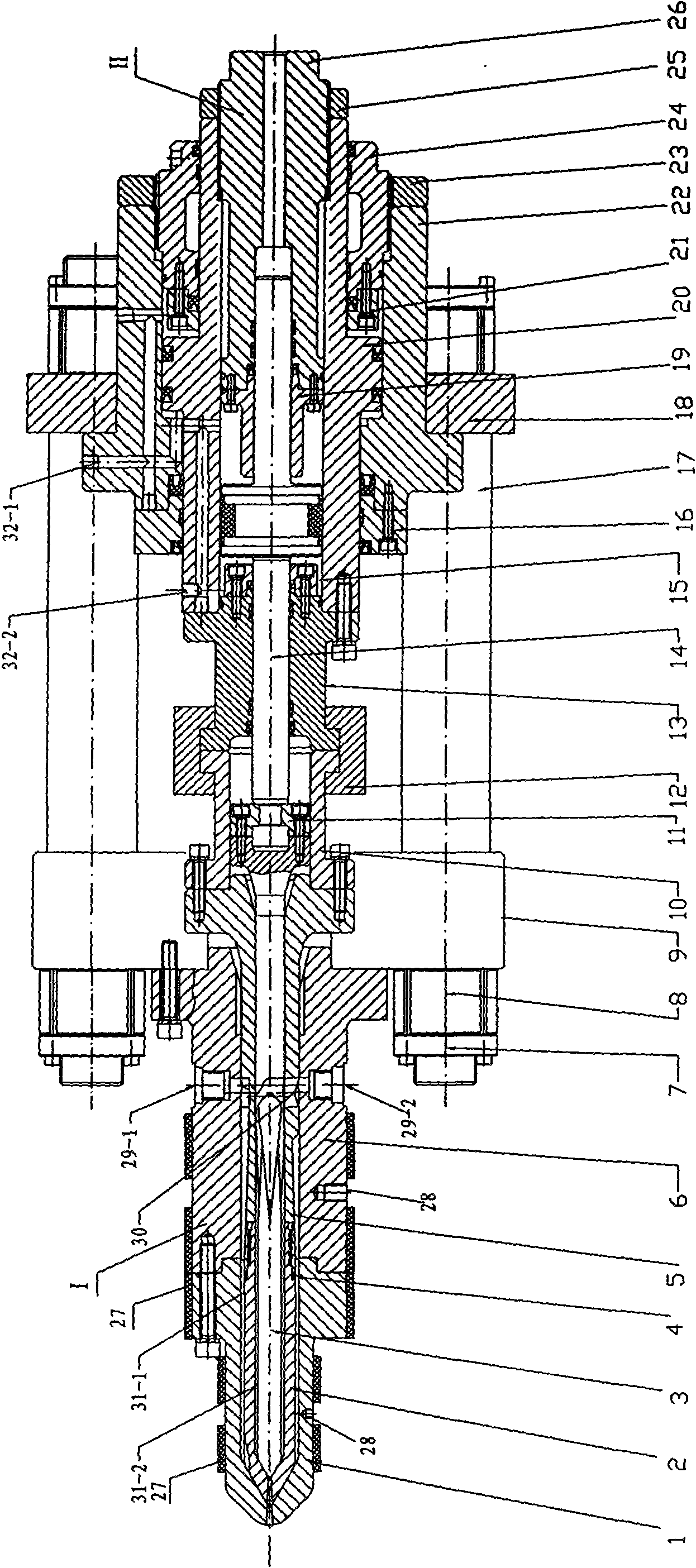

[0015] see figure 1 , the present invention comprises a spool type nozzle device I and a multistage cylinder assembly II, the spool type nozzle device I and the multistage cylinder assembly II are respectively fixed on the front support plate 9 and the rear support plate 18, the front support plate 9, Rear support plate 18 is relatively fixed on four positioning rods 17 with round nut 8, because the two ends of positioning rod 17 are provided with steps, so after front and rear support plates are fixed by round nut 8, front support plate 9 and rear support plate 18 The relative position between them has been determined. In order to prevent the loosening of the nut 8, a round nut 7 is provided and tightened with a loosening screw. Spool type nozzle device 1 comprises: nozzle 1, material distribution body 2, thimble 3, washer 4, material plug body 5, transition seat 6, heating ring 27, thermocouple 28. Wherein the transition seat 6 is fixed on the middle position of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com