Production method of hot-rolled structural steel for clad layer with yield strength of 460MPa

A technology of yield strength and production method, applied in the field of steel plate manufacturing, can solve problems such as ineffective effect, complicated galvanizing process, and increased galvanizing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

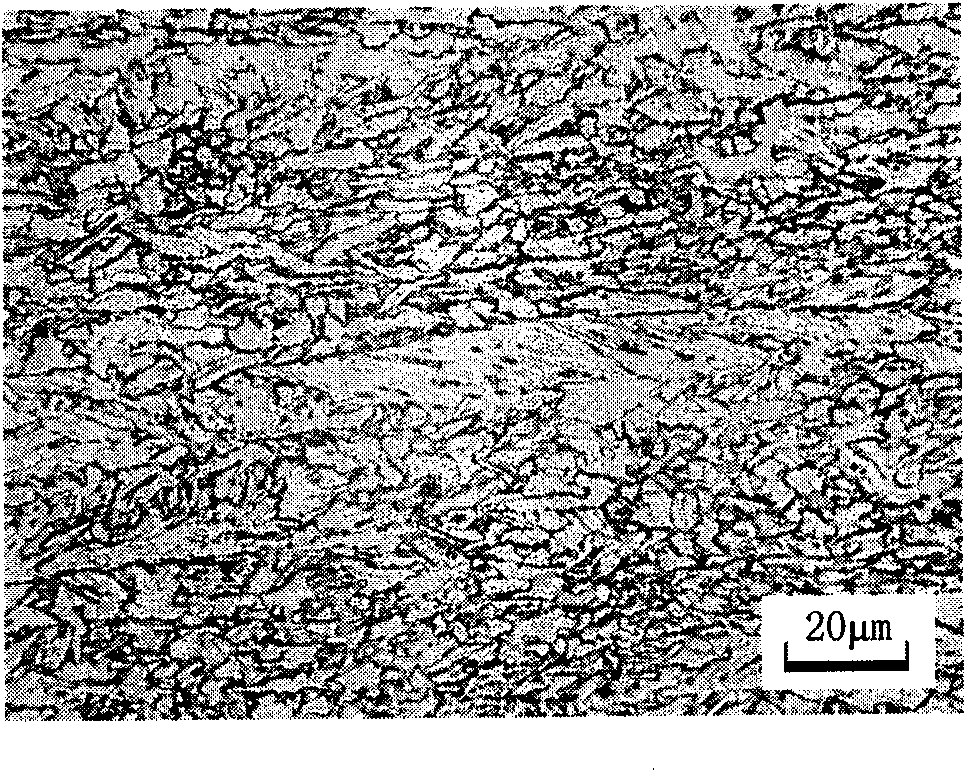

Image

Examples

Embodiment 1

[0070] Steel plate thickness: 5mm

[0071] (1) Steelmaking

[0072] The weight percentage of chemical composition is: C: 0.05%; Si: 0.04%; Mn: 1.42%; P: 0.014%; S: 0.005%; ALs: 0.047%; Nb: 0.051%; .

[0073] Indexes to measure weldability: carbon equivalent Ceq of steel = 0.327, grain sensitivity coefficient Pcm = 0.162.

[0074] (2) Hot rolling

[0075] Slab heating temperature: 1200°C

[0076] Rough rolling exit temperature: 1080°C

[0077] Finishing temperature: 850°C

[0078] Coiling temperature: 600°C

[0079] The product has high strength and good toughness. Yield strength: 520MPa; tensile strength: 575MPa; elongation: 23%; 180 ° cold bending d = 2a intact.

[0080] Galvanizing performance: After the steel plate is hot-dip galvanized, the coating is bright, the color is uniform, and it does not turn black.

Embodiment 2

[0082] Steel plate thickness: 7mm

[0083] (1) Steelmaking

[0084] The weight percentage of chemical composition is: C: 0.10%; Si 0.014%; Mn: 1.30%; P: 0.015%; S: 0.004%; ALs: 0.045%; Nb: 0.035%;

[0085] Indexes to measure weldability: carbon equivalent Ceq of steel = 0.306%; crack sensitivity coefficient Pcm = 0.140.

[0086] (2) Hot rolling

[0087] Slab heating temperature: 1240°C

[0088] Rough rolling exit temperature: 1080°C

[0089] Finishing temperature: 840°C

[0090] Coiling temperature: 540°C

[0091] The product has high strength and good toughness. Yield strength: 510MPa; tensile strength: 595MPa; elongation: 25%; 180 ° cold bending d = 2a intact.

[0092] Galvanizing performance: After the steel plate is hot-dip galvanized, the coating is bright, the color is uniform, and it does not turn black.

Embodiment 3

[0094] Steel plate thickness: 10mm

[0095] (1) Steelmaking

[0096] The weight percentage of chemical composition is: C: 0.069%; Si 0.015%; Mn: 1.40%; P: 0.018%; S: 0.007%; ALs: 0.06%; Nb: 0.041%;

[0097] Indexes to measure weldability: carbon equivalent Ceq of steel = 0.302%; crack sensitivity coefficient Pcm = 0.140.

[0098] (2) Hot rolling

[0099] Slab heating temperature: 1220°C

[0100] Rough rolling exit temperature: 1060°C

[0101] Finishing temperature: 830°C

[0102] Coiling temperature: 600°C

[0103] The product has high strength and good toughness. Yield strength: 485MPa; Tensile strength: 555MPa; Elongation: 27%; -5°C impact energy Akv≥215J; 180°cold bending d=2a intact.

[0104]Galvanizing performance: After the steel plate is hot-dip galvanized, the coating is bright, the color is uniform, and it does not turn black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com