Method and mould arrangement for explosion forming

A technology of forming molds and explosive forming, applied in metal processing equipment and other directions, can solve problems such as expensive and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

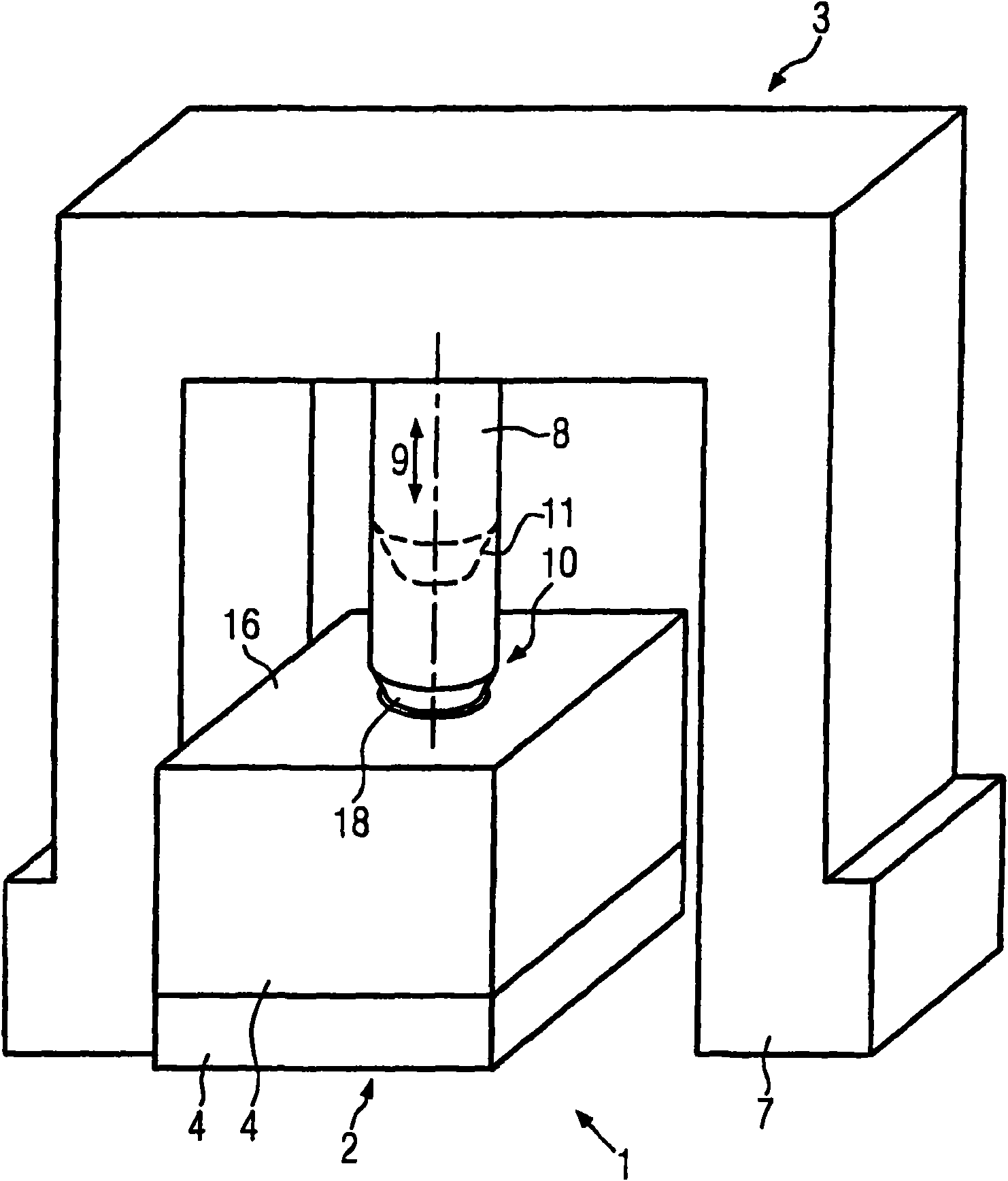

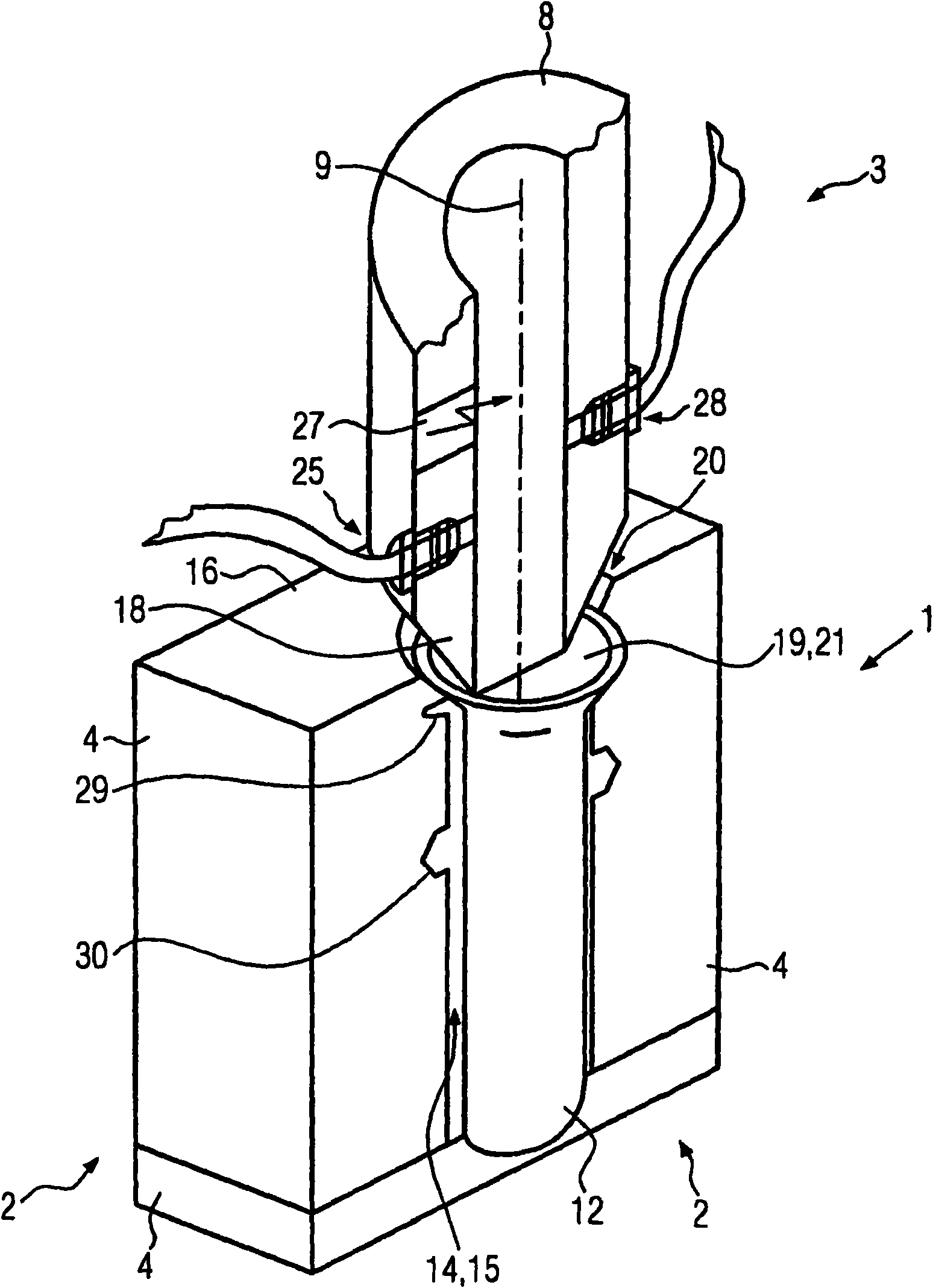

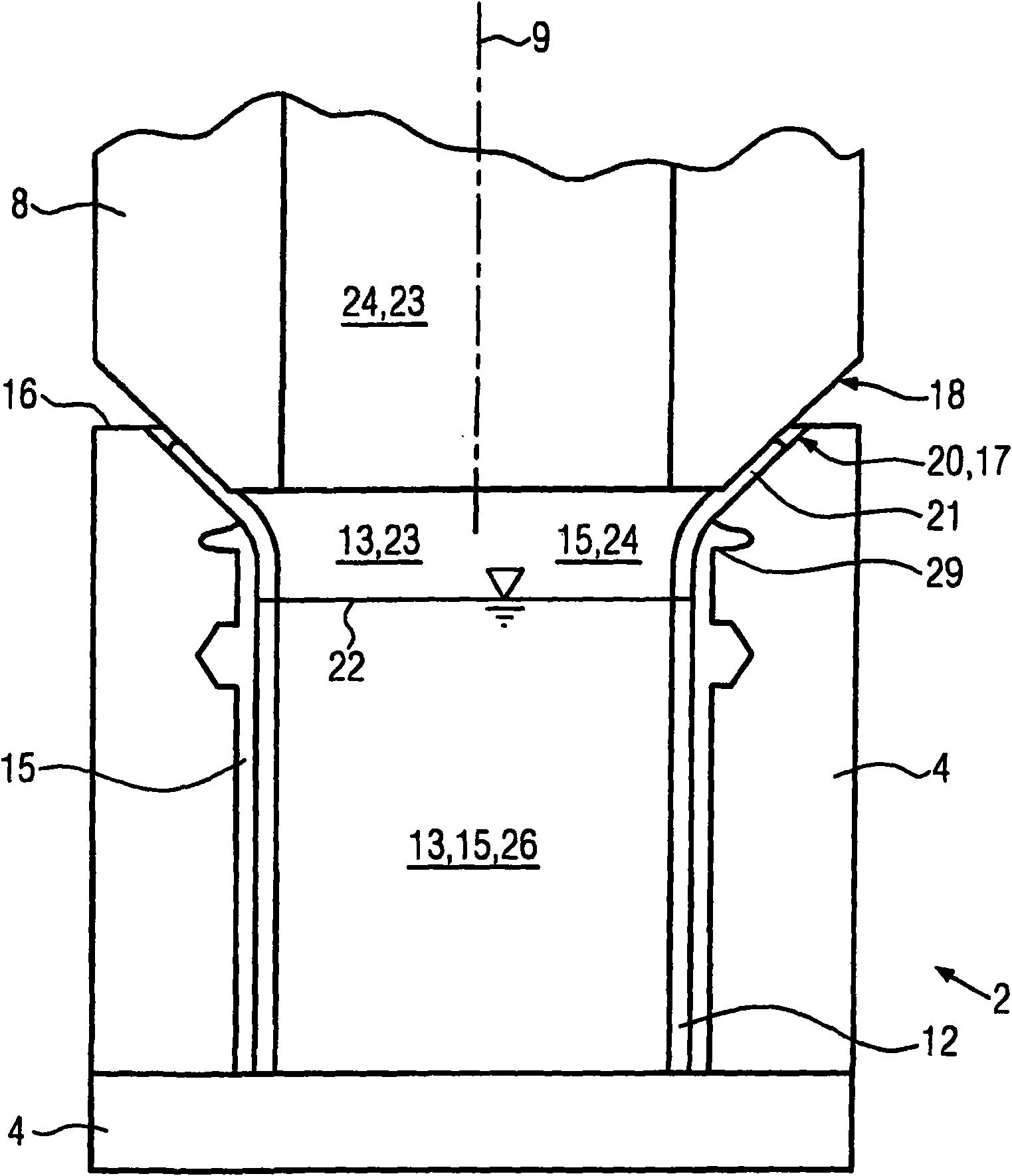

[0034] figure 1 Shown is a perspective view of a mold arrangement 1 according to a first embodiment of the invention. In this exemplary embodiment, the tool arrangement 1 has a shaping tool 2 and an ignition mechanism 3 .

[0035] The molding die 2 is composed of several parts. It consists of a plurality of mold blocks 4 which can be combined to form a forming mold 2 . In the closed state, that is to say when all the forming tool pieces 4 are combined, a tool cavity 14 is formed inside the forming tool 2 which shows the contour of the finished workpiece. In addition, in the contour of forming die 2, there may also be trimming or separating edge 29 and punching die 30, so that the workpiece is cut while explosively forming, as Figures 3 to 5 shown. The tool cavity 14 is at the same time a receiving space 15 for the forming tool 2 . According to the invention the receiving space 15 is at least partially filled with a liquid, as described below Figure 3 to Figure 5 descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com