Technology for improving welding disk circuit of flexible circuit board of back light source

A flexible circuit board and backlight technology, which is applied to printed circuit components, electrical connection printed components, etc., can solve the problems of great impact on consistency, large size error of cover film, and large impact on dimensional accuracy, so as to ensure effective Connecting, preventing pad peeling, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

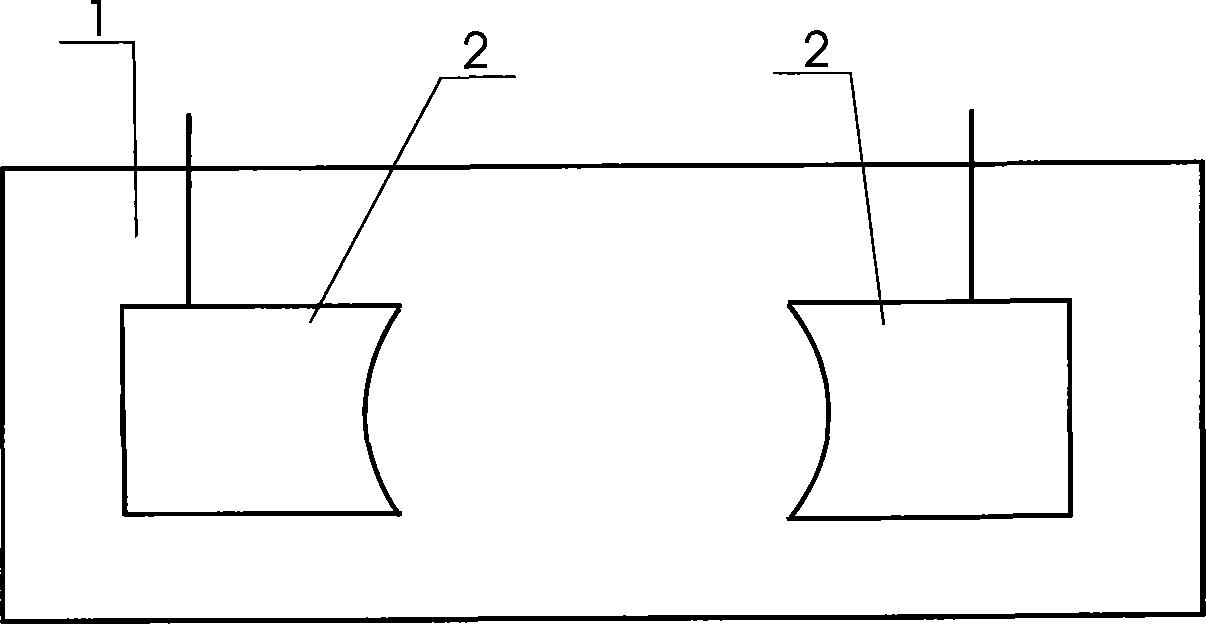

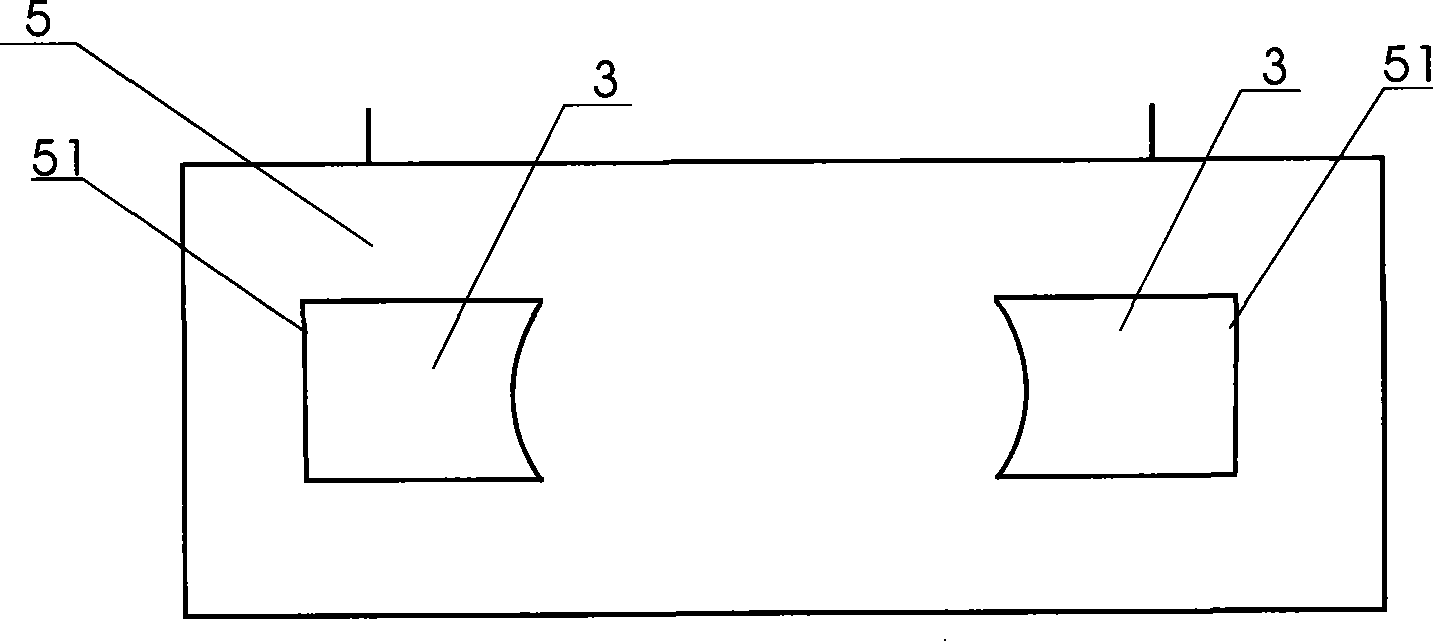

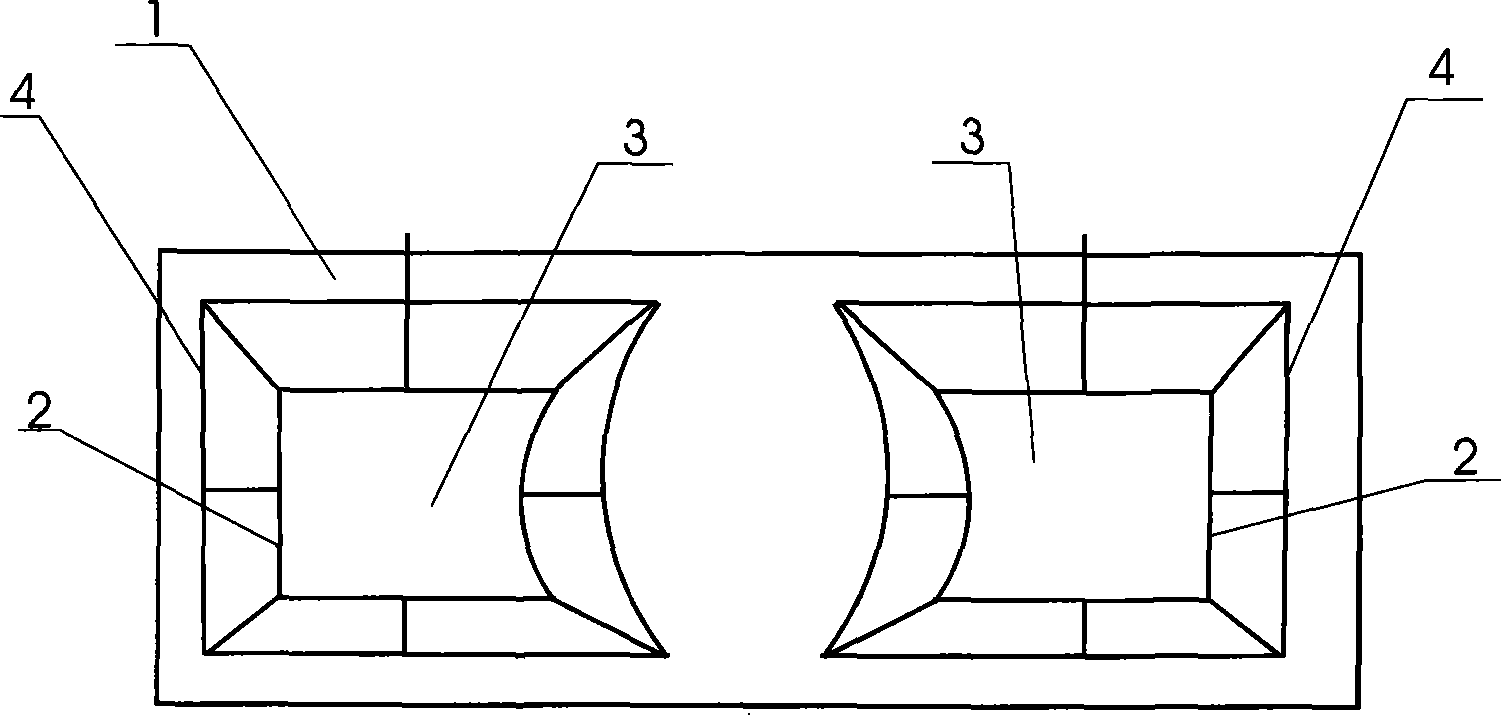

[0016] The pad circuit improvement process of the backlight flexible circuit board is characterized in that the area of the copper skin (2) at the pad of the flexible circuit board (1) is the same size as the pad (3), and a spider web ring circuit is formed around it ( 4), and connected to the pad (3), the window (51) of the cover film (5) is slightly larger than the pad (3), slightly smaller than the periphery of the spider web ring circuit (4), and completely The pad (3) is exposed, and at the same time, the spider web ring circuit (4) around the pad (3) is pressed, the area of the copper skin (2) has been determined, and the copper skin (2) is surrounded by a cover film (5) , can not be soldered, no matter how large the area of the window (51) of the cover film (5) is, the size of the pad (3) will not change, that is, the area of the pad (3) will not change, because the copper skin (2) The area is etched, and the tolerance can be guaranteed to be in the range of + / -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com