Method for designing crowbar resistor for passing through low voltage of double-fed type wind generator system

A technology of wind power generation system and low-voltage ride-through, which is applied in wind power generation, single-network parallel feeding arrangement, etc. It can solve the problems that the crowbar circuit design cannot achieve the expected effect, and the theoretical basis analysis of crowbar resistance parameter design is insufficient. Achieve the effect of small overcurrent and ensure safety

Inactive Publication Date: 2011-05-11

TSINGHUA UNIV +1

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

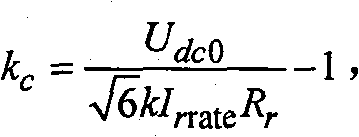

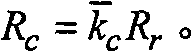

The invention relates to a method for designing a crowbar resistor for passing through the low voltage of a double-fed type wind generator system, belonging to the technical field of wind power generation and comprising the following steps: firstly, acquiring the rotor turns ratio, the rotor resistance, the rotor rated current and the rotor current upper limit of a double-fed generator of the wind generator system; computing current overload multiples according to the rotor rated current and the rotor current upper limit; acquiring the DC bus voltage of the wind generator system; computing a per-unit parameter kc of the crowbar resistor according to the DC bus voltage, the current overload multiples, the rotor rated current and the rotor resistance; obtaining a modified per-unit parameter kc after properly increasing the per-unit parameter kc; and finally, designing the resistance value of the crowbar resistor to be Rc=kcRr. The method designs the crowbar resistor according to a principle of the LVRT process of a DFIG system, adopts the clamping effect of a DC bus in the LVRT process, ensures the LVRT property while having less current and ensures the safety of a fly-wheel diode of a rotor current transformer.

Description

technical field The invention relates to a crowbar resistance design method for low-voltage ride-through of a doubly-fed wind power generation system, belonging to the technical field of wind power generation. Background technique For a grid-connected wind power generation system using a doubly-fed generator (hereinafter referred to as DFIG), when the grid voltage drops due to a short-circuit fault, it will cause a DC component in the flux linkage of the generator stator and rotor, and then induce a relatively high voltage on the generator rotor side. Large induced electromotive force. When the induced electromotive force on the rotor side exceeds the voltage control capability of the rotor-side converter, a large short-circuit current will appear on the rotor side, which may cause damage to the rotor-side converter and generator in severe cases. Therefore, during a grid short circuit, the wind power generation system will take some necessary protection measures to ensure i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02J3/38

CPCY02E10/76

Inventor 周宏林杨耕刘军金继军路春英

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com