Thin film solar cell component and encapsulation method thereof

A solar cell and packaging method technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of shortening the service life of components, poor moisture resistance, and easy corrosion of components, and achieves improved impact resistance and good resistance. The effect of mechanical damage ability and good adaptability to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The accompanying drawings illustrate exemplary embodiments of the invention, reference is made in order to gain a full understanding of the invention, its advantages and objects achieved by its practice. Hereinafter, the present invention will be described in detail by explaining exemplary embodiments of the invention with reference to the accompanying drawings. Similar or identical reference numerals in the drawings indicate similar or identical elements.

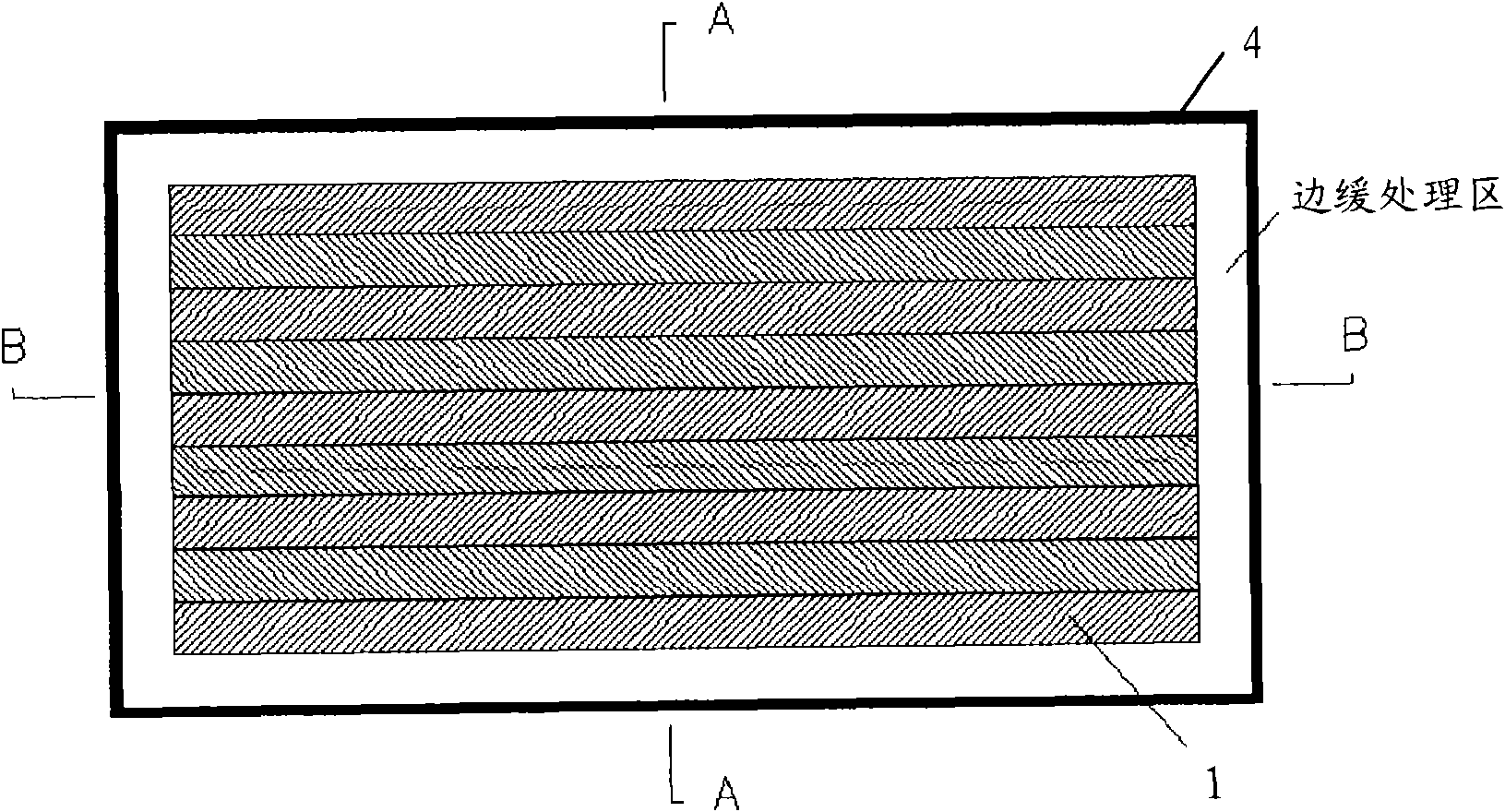

[0022] figure 1 It is the front top view of the solar cell module. exist figure 1 In , the solar cell module is shown in a rectangular surface appearance, but other shapes and sizes can be adopted according to actual needs. Looking down from the front of the solar cell module, the thin-film cells arranged in order can be seen through the light-receiving glass panel of the cell sheet. The area around the thin film battery is the edge treatment area.

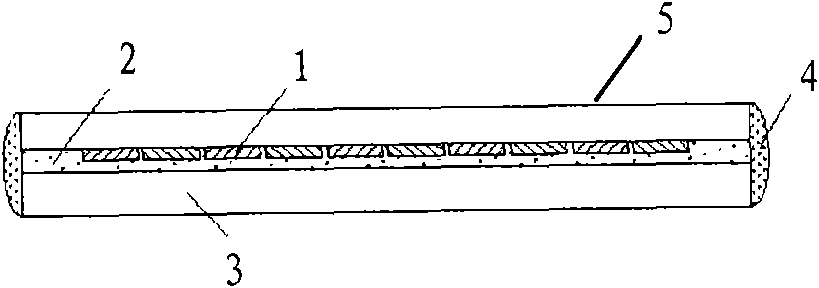

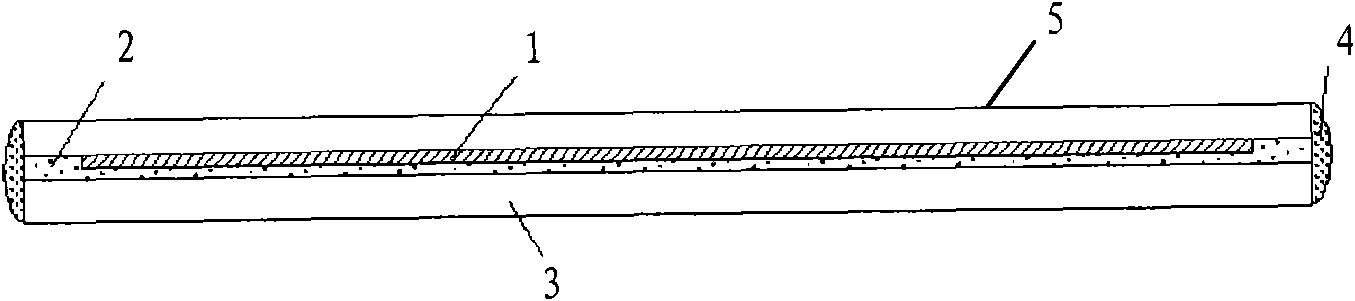

[0023] figure 2 yes figure 1 The cross-sectional view of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com