Radiating fins of crossflow cooling tower

A technology of cooling towers and heat sinks, which is applied to water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of splashing water droplets, wasting water resources, etc., and achieve good heat dissipation coefficient and sufficient heat exchange , Good water collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

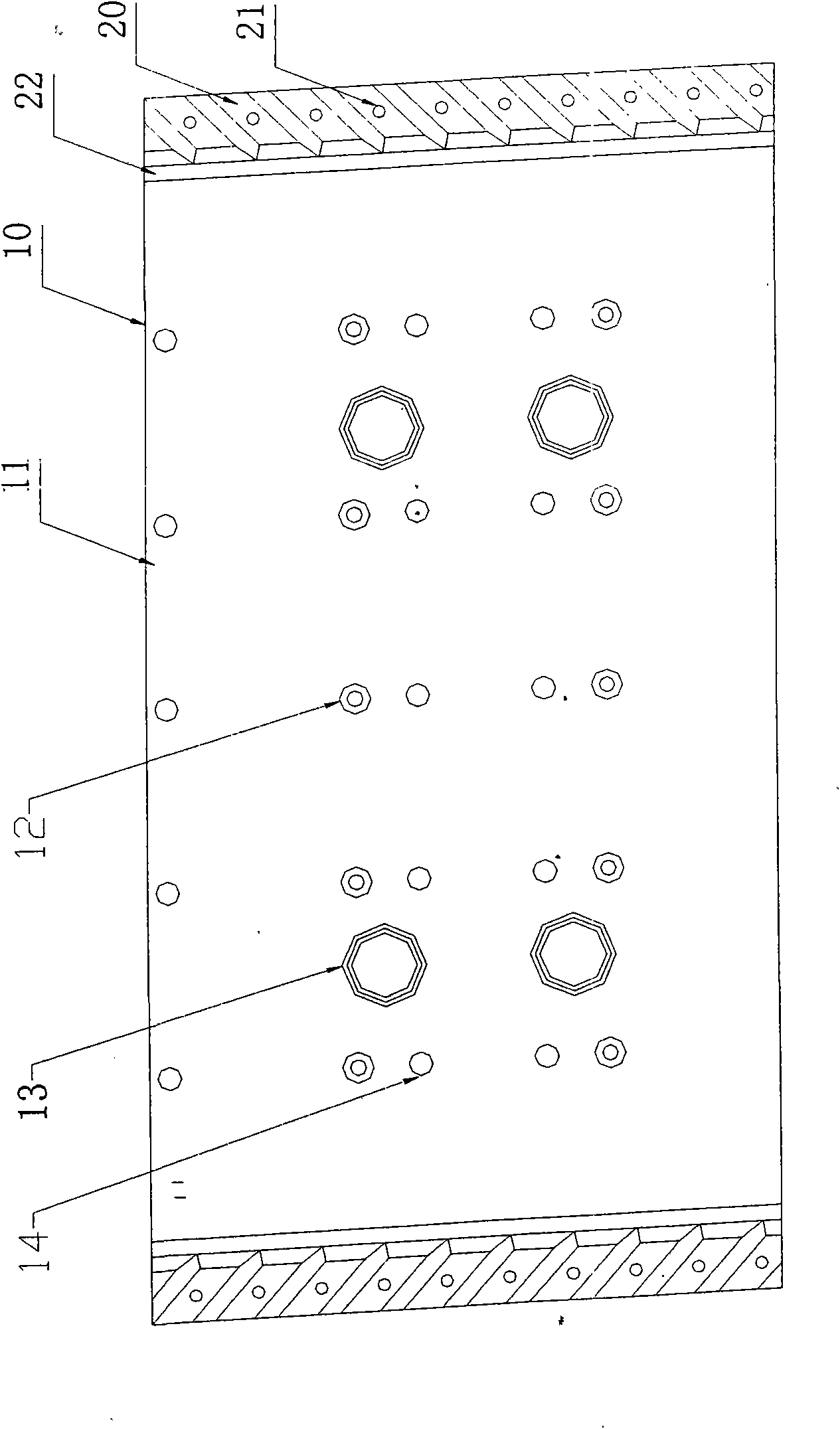

[0011] The present invention is a special heat dissipation sheet for a cross-flow cooling tower. The overall structure of the present invention can be seen from the figure. The main body 10 is designed with concave and convex hemispherical holes 11, and the staggered arrangement can greatly increase the number of sheets. At the same time, there is a stamping hole 13 designed on the main sheet 10, and a reasonable structure design is adopted to facilitate the insertion of the steel pipe and at the same time to ensure that each radiating fin passing through maintains the same height. The material main body 10 is also provided with a certain number of protruding nodes 12, and the nodes 12 maintain a certain height, which can ensure that each heat sink is at a certain distance, so that each heat sink has constant wind resistance and small resistance under a certain distance. . A die point 14 is also designed on the main body 10 of the sheet material, which facilitates the combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com