Preshrinking device for warp-beam preshrinking coiler

A rolling machine and pre-shrinking technology, which is applied in the field of textile machinery, can solve the problems of large energy consumption and environmental pollution, and achieve the effect of low energy consumption and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

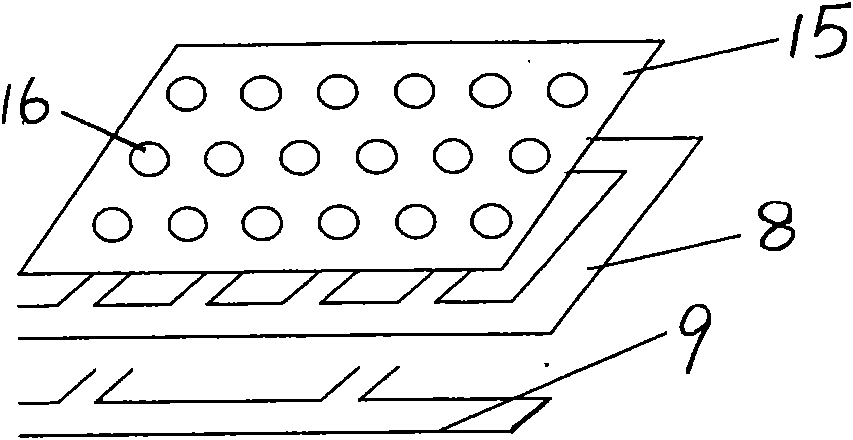

[0009] The present invention mainly includes a casing 1 and a frame 2 arranged in the casing. The difference between it and the prior art is that the frame is provided with three groups of pre-shrinking rollers 3 arranged in parallel, and a heating chamber 4 is arranged below the pre-shrinking rollers. The top of the pre-shrinking roll is provided with a steam suction exhaust device 5, and the steam suction exhaust device is formed by connecting a suction hood 6. with an exhaust pipe 7 connected to the suction hood. The heating chamber is provided with 4 transmission rods, the bottom of the heating chamber is provided with a steel plate 15, and a thermal oil pipe 8 and a steam pipe 9 are laid below the steel plate. Evenly distributed steam holes 16 are arranged on the steel plate, 2-8 thermal oil pipes and 1-4 steam pipes are arranged below the steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com