Degradable composite spunlaced nonwovens and manufacturing method thereof

A technology of non-woven fabrics and spunlace, applied in the direction of non-woven fabrics, textiles and papermaking, chemical instruments and methods, etc., can solve the problems of rising cost of viscose fiber, high product cost, non-degradable and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

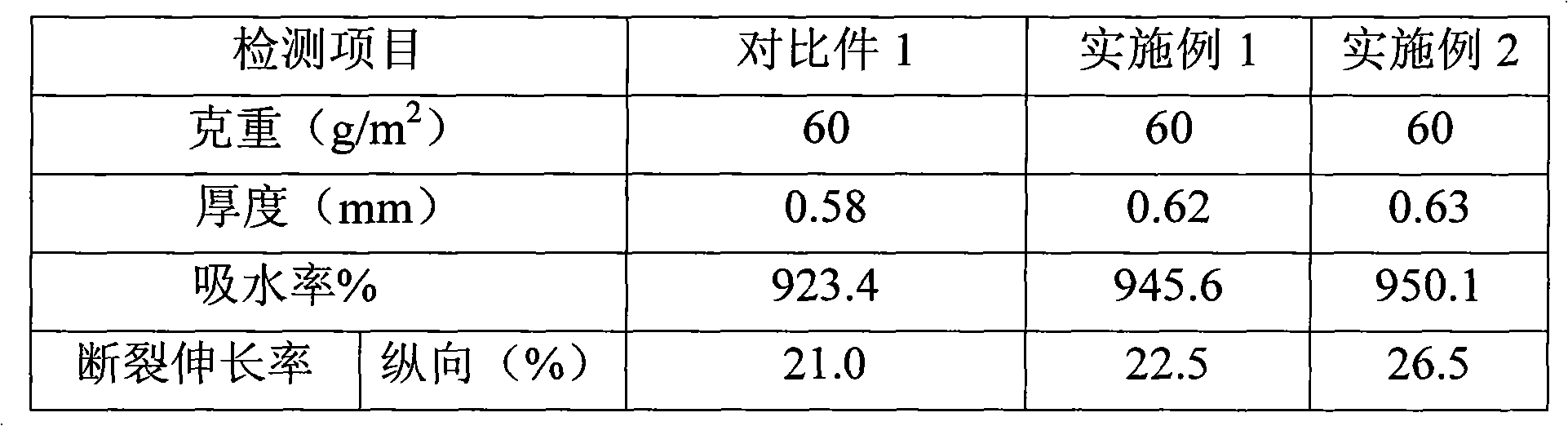

[0016] The upper layer of the embodiment of the present invention is carded into a web, the easily degradable fiber of embodiment 1 is 100% viscose, the easily degradable fiber of embodiment 2 is 100% tencel, and the lower layer of embodiment 1 and 2 is polylactic acid nonwoven fabric, Air-laid with wood pulp fibers in the middle, processed and entangled by unwinding on-line or off-line by spunlace.

[0017] The concrete production method of embodiment 1,2 is:

[0018] a. Through the existing air-laid equipment (the model is A.CELLI WINGFORMER, such as imported equipment from Italy), the wood pulp cardboard is broken into wood pulp fibers and spread into a uniform network, that is, to form wood pulp fiber air-laid. In order to ensure that the crushed wood pulp fiber does not form a ball in the conveying pipeline, the flow velocity in the pipeline must be controlled at 17-25m / s, and the efficiency of the conveying fan is 110%. The efficiency of the primary suction fan is 110%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com