A kind of manufacturing method of four-layer composite spunlaced nonwoven fabric

A technology of non-woven fabrics and manufacturing methods, applied in the direction of non-woven fabrics, textiles, papermaking, thorn patterns, etc., can solve the problems of use effect and hand feeling, easy to fall off, easy to deform, etc., to achieve soft and thick hand feeling, low production cost Reduce and enhance the effect of vertical and horizontal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

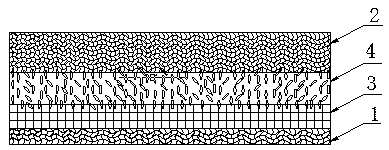

[0025] Such as figure 1 As shown, a four-layer composite spunlaced nonwoven fabric includes a short fiber layer 1 obtained by opening and carding a short fiber material into a web process, and a carded fiber layer 2 made by an air carding process, wherein the short fiber Layer 1 is used as the bottom layer, and its grammage is 11-30g / m 2 ; The carded fiber layer 2 is used as the top layer, and the grammage is 12-100g / m 2 , the staple fiber layer 1 is successively laid with a filament fiber layer 3, a water-absorbing fiber web layer 4 and a carded fiber layer 2, and after 7 passes of high-pressure water needle spunlace, the staple fiber layer 1, the filament fiber layer 3, and the water-absorbing fiber layer The net layer 4 and the carded fiber layer 2 are entangled with each other and solidified into a net to form a composite, and then dehydrated in an oven to obtain high strength, high water absorption, good uniformity, and a soft and thick feel. The grammage is 40-150g / m 2...

Embodiment 2

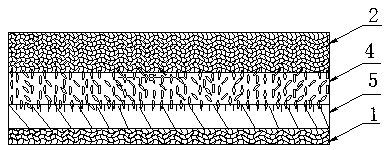

[0028] Such as figure 2 As shown, the hot-rolled cloth layer 5 is used to replace the filament fiber layer 3 in Example 1: a four-layer composite spunlaced nonwoven fabric, including short fiber obtained by opening and carding the short fiber material. Layer 1, a carded fiber layer 2 made by an air carding process, wherein the short fiber layer 1 is used as the bottom layer, and its grammage is 11-30g / m 2 ; The carded fiber layer 2 is used as the top layer, and the grammage is 12-100g / m 2 , the short fiber layer 1 is successively laid with a hot-rolled cloth layer 5, a water-absorbent fiber web layer 4 and a carded fiber layer 2, and after 7 passes of high-pressure water needle spunlace, the short-fiber layer 1, hot-rolled cloth layer 5, water-absorbent fiber layer The net layer 4 and the carded fiber layer 2 are entangled with each other and solidified into a net to form a composite, and then dehydrated in an oven to obtain high strength, high water absorption, good uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com