Drawable gas permeable brick

A technology of air-permeable bricks and air chambers, which is applied in the manufacture of converters, charge manipulation, lighting and heating equipment, etc. It can solve the problems that the successful extraction of the air-permeable brick core cannot be fully guaranteed, the structure of the air-permeable brick core body is complex, and the production process is cumbersome. , to achieve the effect of uncomplicated production, improve the success rate of drawing, and avoid weld cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

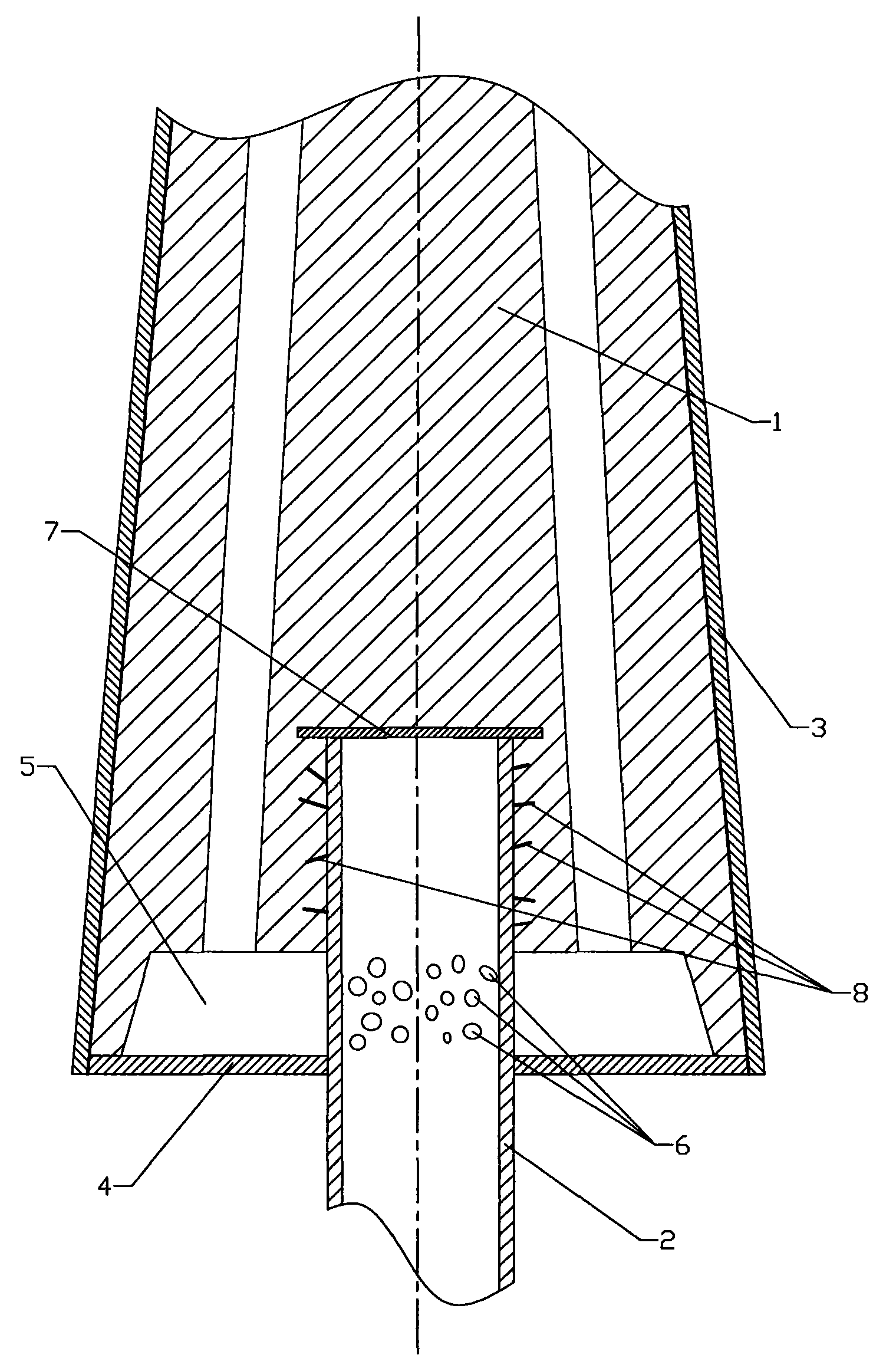

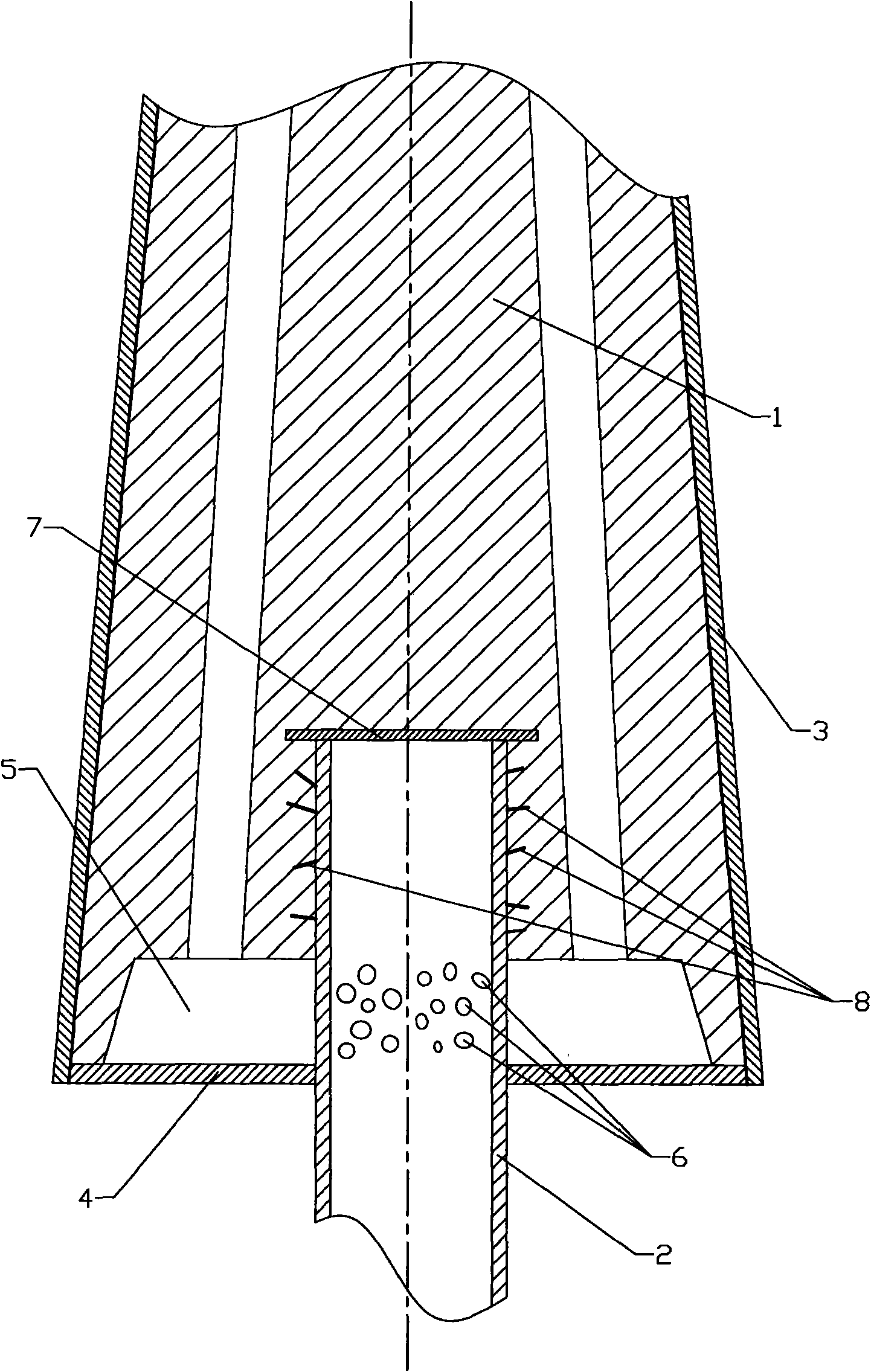

[0028] As shown in FIG. 1 , it is a preferred embodiment of the drawable breathable brick of the present invention, and the drawable breathable brick includes a breathable brick body 1 and an air supply pipe 2 . The breathable brick body 1 is made of refractory material, and its exterior is wrapped with a steel shell 3. The lower end of the steel shell 3 is welded with a bottom plate 4, and the bottom plate 4 has a certain thickness. The bottom surface of the breathable brick body 1 and the An air chamber 5 is formed between the bottom plates 4 . The outer surface of the breathable brick body 1 has a certain taper. In the working state, the breathable brick body 1 is installed in the installation hole of the seat brick, and the inner surface of the installation hole is taper to the outer surface of the breathable brick body 1. match. The air supply pipe 2 is sealed and connected with the bottom plate 4, the upper end of the air supply pipe 2 passes through the air chamber 5 a...

Embodiment 2

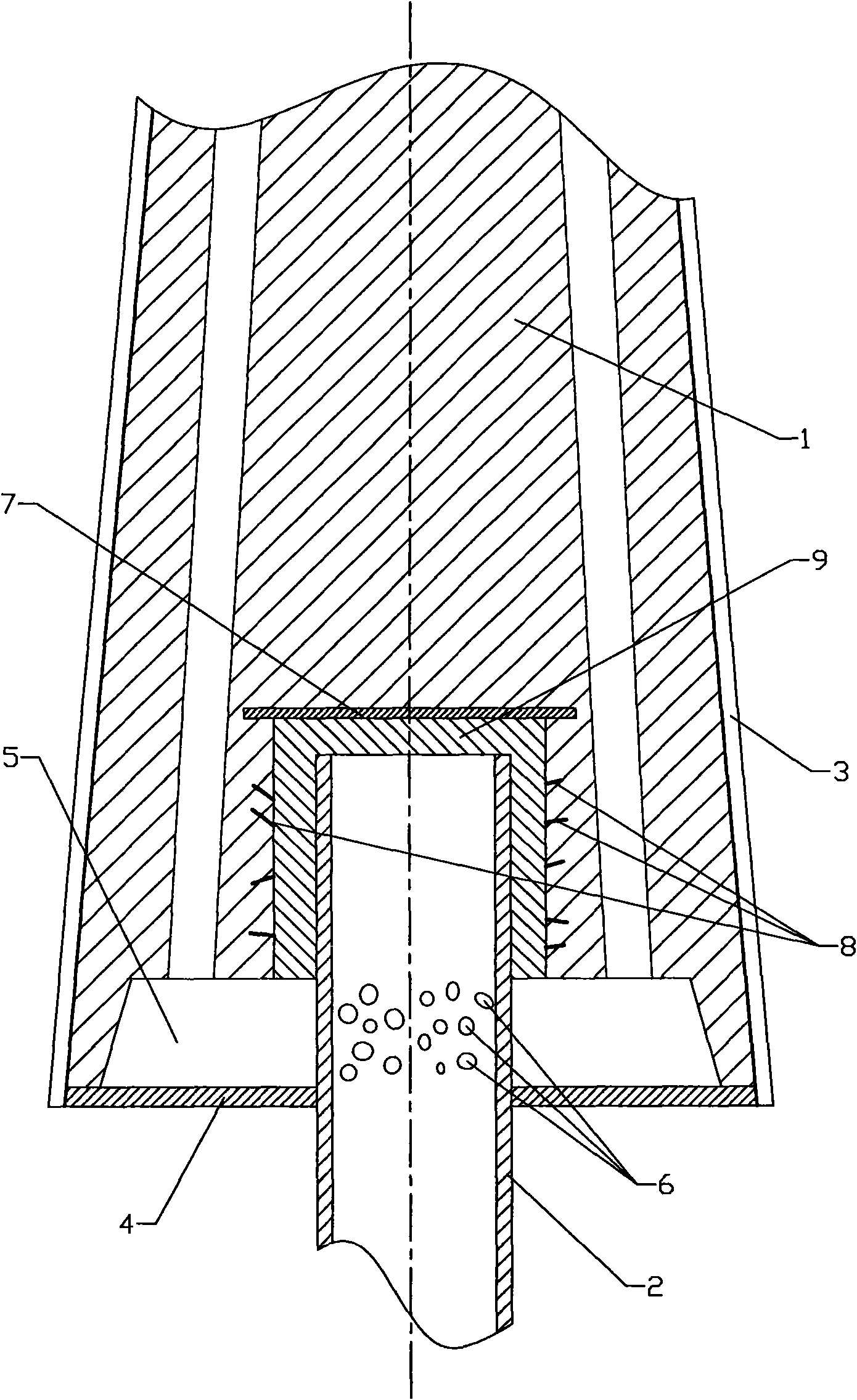

[0032]As shown in Figure 2, it is another embodiment of the drawable air permeable brick of the present invention. Its basic structure is similar to that of the drawable air permeable brick described in Embodiment 1. The sleeve 9 inside the air brick body 1 with the opening downward, the anchor plate 7 fixedly connected to the top end of the sleeve 9 , and the anchor piece 8 fixedly connected to the outer wall of the sleeve 9 . In this embodiment, the sleeve 9 is cylindrical, and the sleeve 9 is detachably connected to the part where the air supply pipe 2 enters the air brick body 1. In this embodiment, the sleeve The inner diameter of the sleeve 9 matches the outer diameter of the air supply pipe 2, the inner wall of the sleeve 9 is formed with an internal thread, the outer wall of the air supply pipe 2 is formed with an external thread that matches the internal thread, and through the internal Through the cooperation of the thread and the external thread, the sleeve 9 is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com