Method for adding a denitriding sequencing batch reactor activated sludge reaction carbon source

A serial intermittent, activated sludge technology, applied in the field of real-time control, can solve problems such as denitrification cannot be carried out smoothly, and achieve the effect of optimizing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

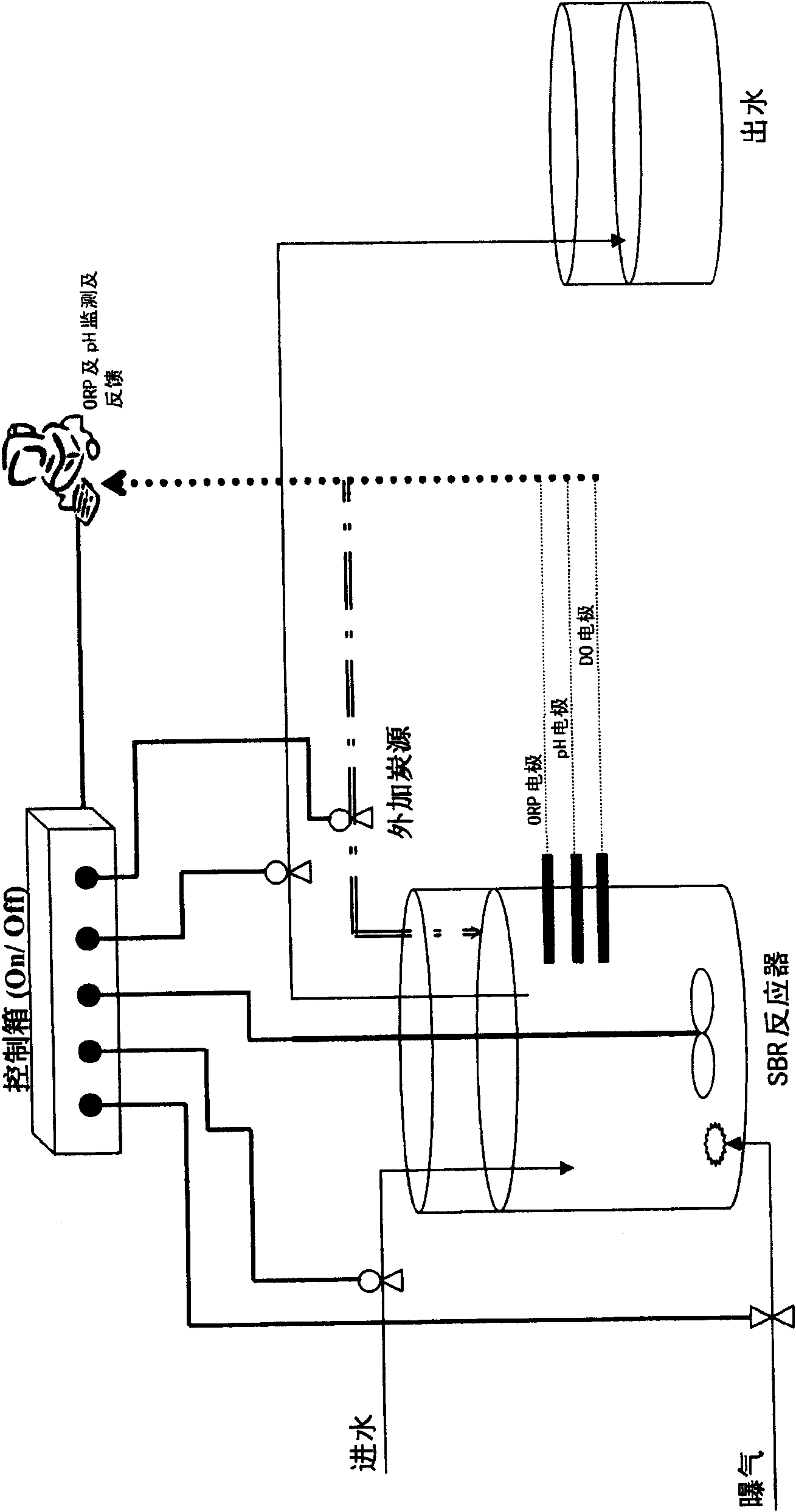

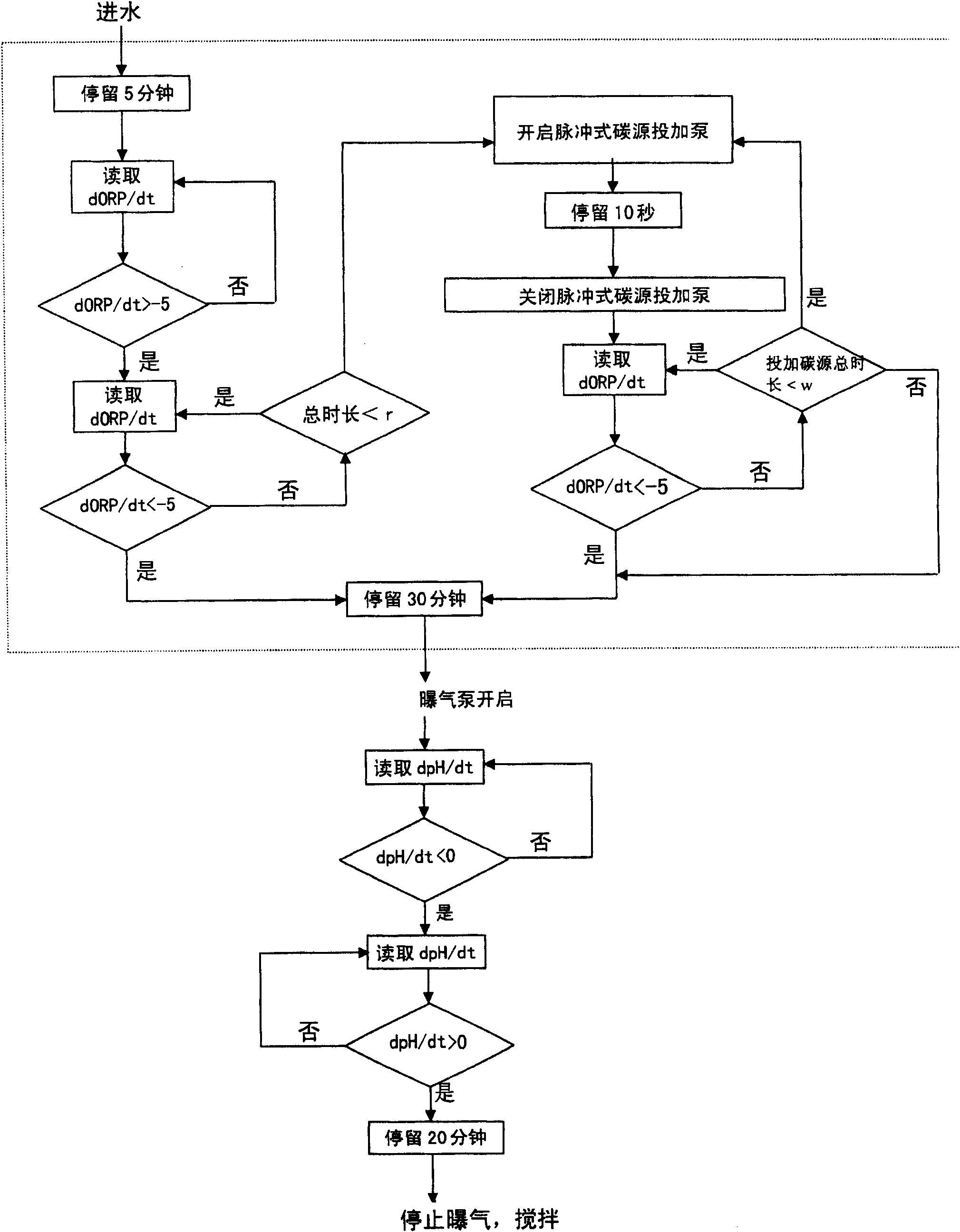

Method used

Image

Examples

Embodiment 1

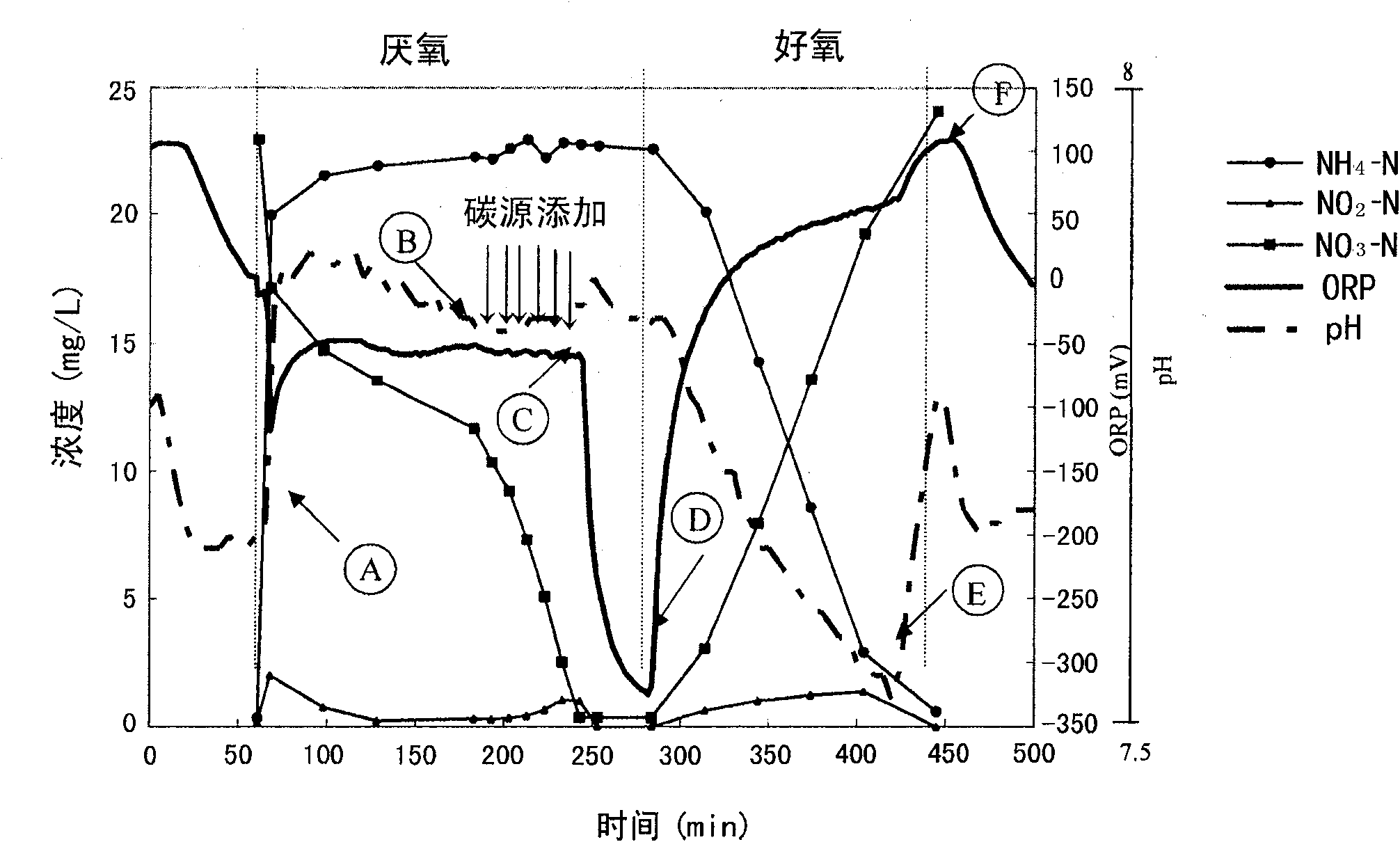

[0019] Example 1: In a certain intensive pig raising wastewater treatment, when the total organic carbon / total nitrogen (TOC / TN) in the influent was 0.69, due to the obvious lack of carbon source in the influent, livestock and poultry manure was used as the Additional carbon source. The tracer analysis that adopts the system processing of the present invention such as figure 2 shown. A is the start of anaerobic (anoxic) after water ingress. With the wastewater entering the system and the nitrate produced in the aerobic process of the previous cycle, the carbon source in the influent is used for denitrification reaction. Due to the lack of carbon source in the influent, the livestock and poultry manure diluted from point B is 10 grams per pulse. Adding to the system, after the first addition, the nitrate concentration only slowly dropped from 12mg / L to 10mg / L, and the second addition started because the denitrification did not reach complete. This cycle to the sixth dosing,...

Embodiment 2

[0021] Implementation 2: In the landfill leachate treatment process, under the condition of low C / N ratio influent, in this embodiment, methanol is used as an additional carbon source, and the trace analysis of the system treatment of the present invention is as follows: Figure 4 shown. Due to the lack of carbon source in the influent, methanol diluted from point B was added to the system at 10 ml per pulse. After the first addition, the nitrate concentration was only slowly reduced from 12 mg / L to 10 mg / L. Nitrification, the second dosing begins. This cycle until the third dosing, the nitrate concentration is close to zero, and at the same time, there is a significant slope change on the ORP curve, and point C is the denitrification control point. Exogenous nutrient addition ceases at point C. Point D is the starting point of aeration, and the ORP rises rapidly. As the nitrification proceeds, the concentration of ammoniacal nitrogen drops rapidly, and at point E, the nitr...

Embodiment 3

[0022] Embodiment 3: Due to management methods and seasonal changes, the water quality of livestock wastewater varies greatly, especially the ammoniacal nitrogen content in the wastewater is very high, Figure 5 Because the present invention is used for ORP and pH curves with a TOC / TN ratio of 0.5-1.6 in a wide range, in the range of TOC / TN ratio of 1.3-1.6, the carbon source provided by the influent can ensure the smooth progress of denitrification. The denitrification point and nitrification point in the oxygen (anoxic) and aerobic stages are obvious. In the range of TOC / TN ratio of 0.5-0.8, it is necessary to add an external carbon source to achieve complete denitrification. Here, the changing HRT is inversely proportional to the C / N ratio, ie a higher C / N ratio corresponds to a shorter HRT. In the two ranges of C / N ratios, the HRT was 6.3 days and 10 days, respectively. This is due to the fact that under low C / N ratio influent conditions, the system needs to judge whether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com