A method for controlling surface color difference of hot-rolled pickled sheet

A control method, hot-rolled pickling technology, which is applied in metal rolling, roll speed control, temperature control, etc., can solve the problems that the product qualification rate is greatly affected, and the product cannot meet the user's requirements for surface quality, so as to improve the surface quality , Eliminate the effect of water mark color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for controlling the surface color difference of a hot-rolled pickled plate. When producing a hot-rolled substrate, the following measures are taken:

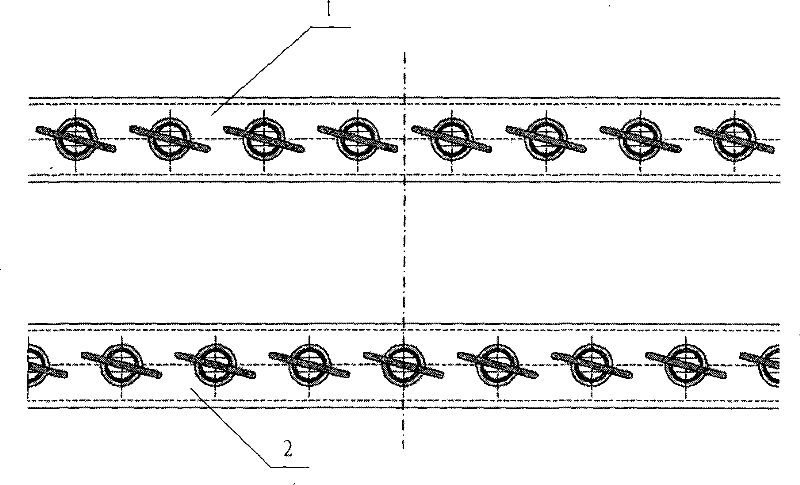

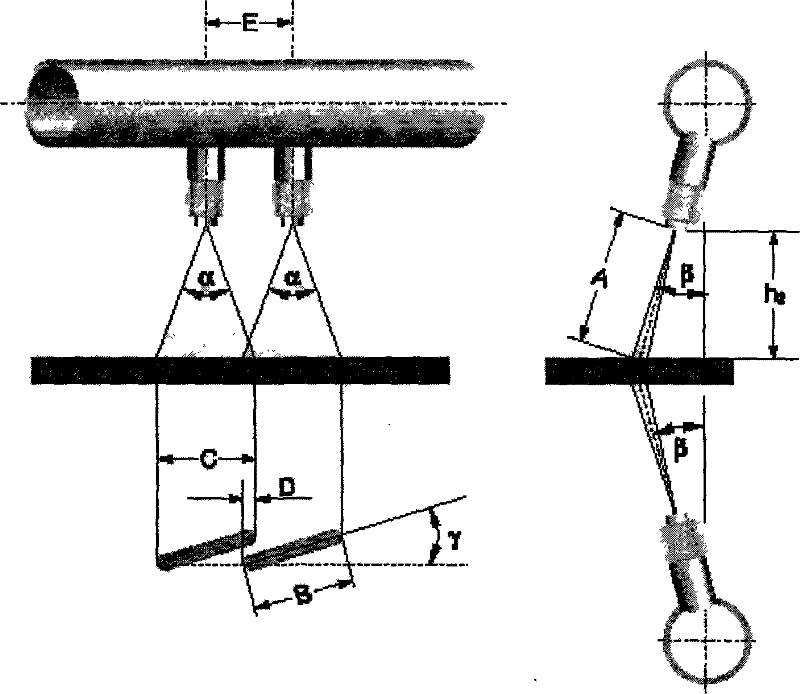

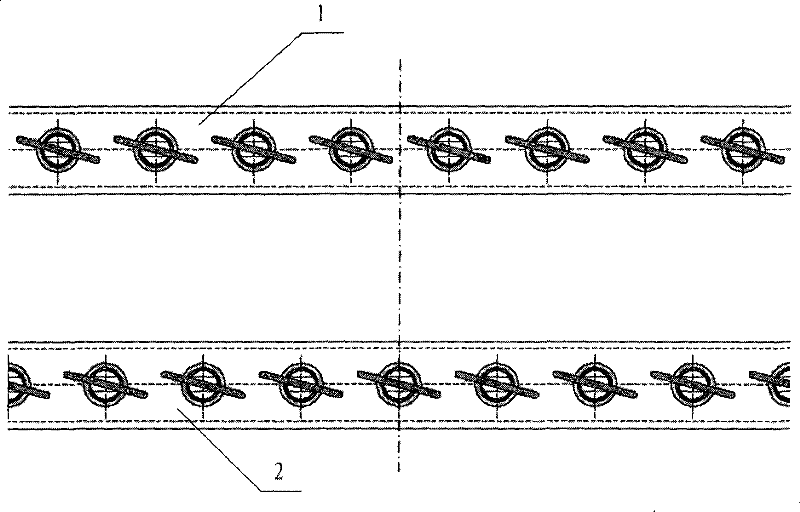

[0025] 1) High-pressure water descaling nozzles are used on both sides of the roughing mill for descaling, and the descaling header nozzle 1 on the roughing mill inlet side and the descaling header nozzle 2 on the roughing mill outlet side are arranged in a staggered manner; the overlapping amount (D )7~10mm, vertical nozzle height (h2)150~250mm, descaling water pressure 15~25MPa;

[0026] 2) The four-roll reversible roughing mill adopts 3 to 5 passes for rolling. The high-pressure water descaling at the entrance side of the pass, the entrance side of the roughing mill is the position where the billet enters the rolling mill, and the high-pressure water descaling between the stands of the finishing rolling mill; 1st, 4th, and 5th pass high-pressure water descaling at the entrance side (high-pressure water descal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com