Linear heat source

A wire heat source, wire-shaped technology, applied in the direction of electric heating device, heating element material, heating element shape, etc., can solve the problems of low strength of carbon fiber paper, high density of carbon fiber paper, large thickness of carbon fiber paper, etc., to achieve high electrothermal conversion efficiency, The effect of fast heat exchange and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The linear heat source of the technical solution will be described in detail below in conjunction with the accompanying drawings.

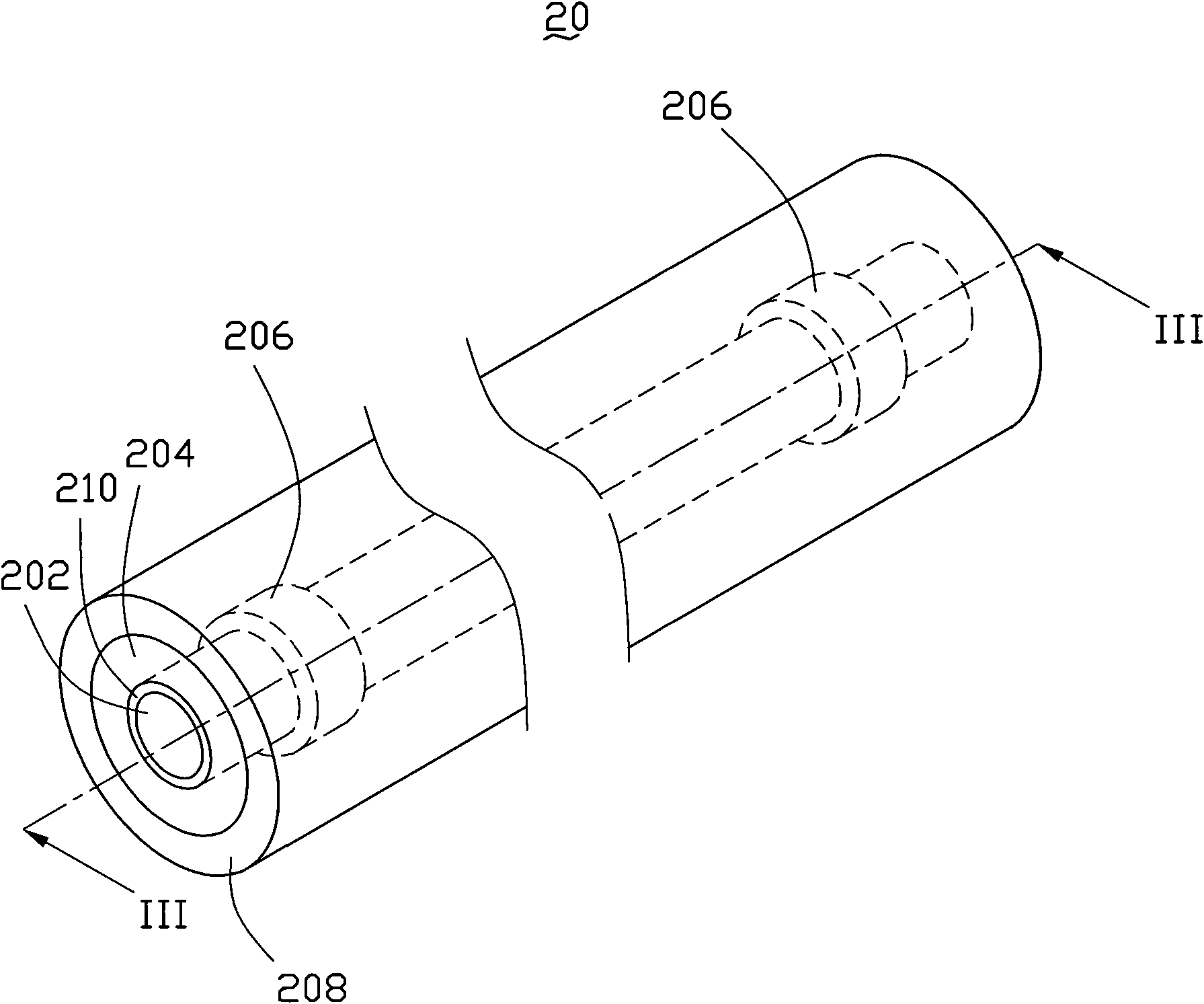

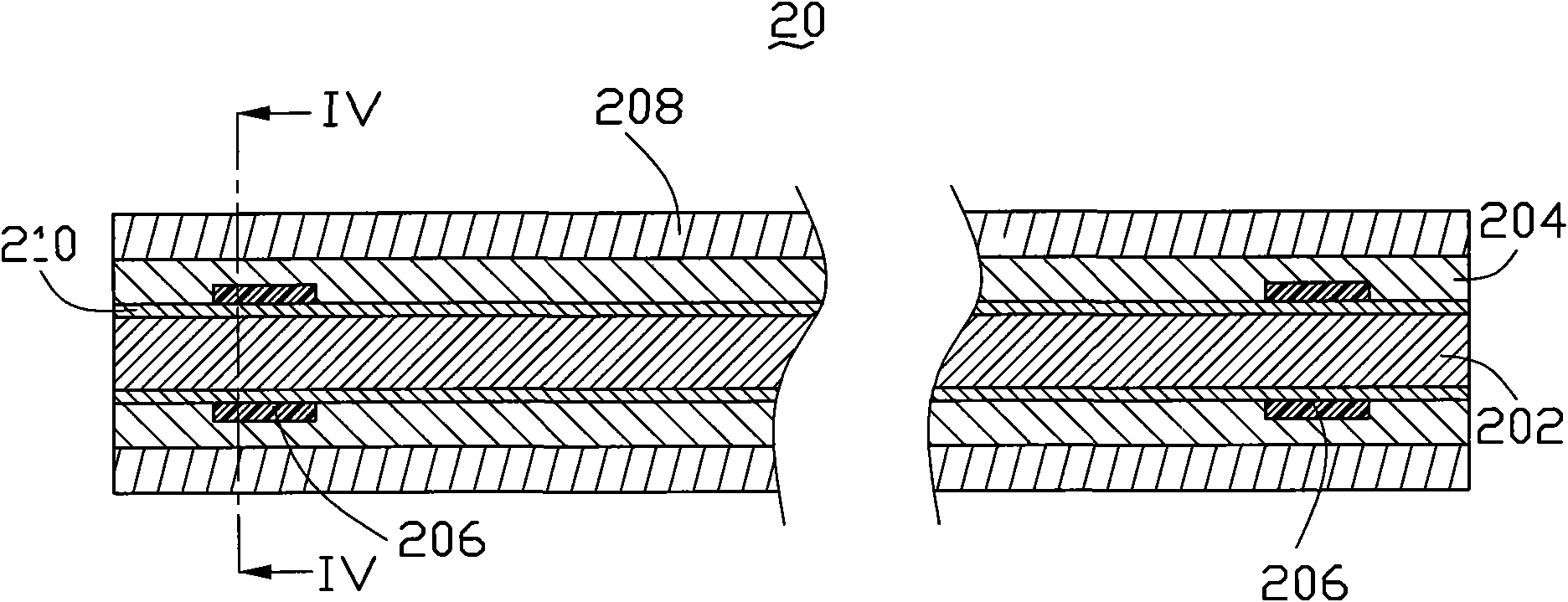

[0015] see Figure 2 to Figure 4 The embodiment of the technical solution provides a linear heat source 20, the linear heat source 20 includes a linear base 202; a reflective layer 210 is disposed on the surface of the linear base 202; a heating layer 204 is disposed on the surface of the reflective layer 210; Two electrodes 206 are spaced apart on the surface of the heating layer 204 and electrically connected to the heating layer 204 ; and an insulating protection layer 208 is disposed on the surface of the heating layer 204 . The length of the linear heat source 20 is not limited, and the diameter is 0.1 micron to 1.5 cm. The diameter of the linear heat source 20 in this embodiment is preferably 1.1 millimeters to 1.1 centimeters.

[0016] The linear base 202 plays a supporting role, and its material can be hard materials, such as cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com