Fast hydrogen making device capable of automatically starting in power-down condition

An automatic start and fast technology, applied in hydrogen production, circuits, fuel cells, etc., can solve the problems of low hydrogen purity, pollution, troublesome operation, etc., and achieve the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

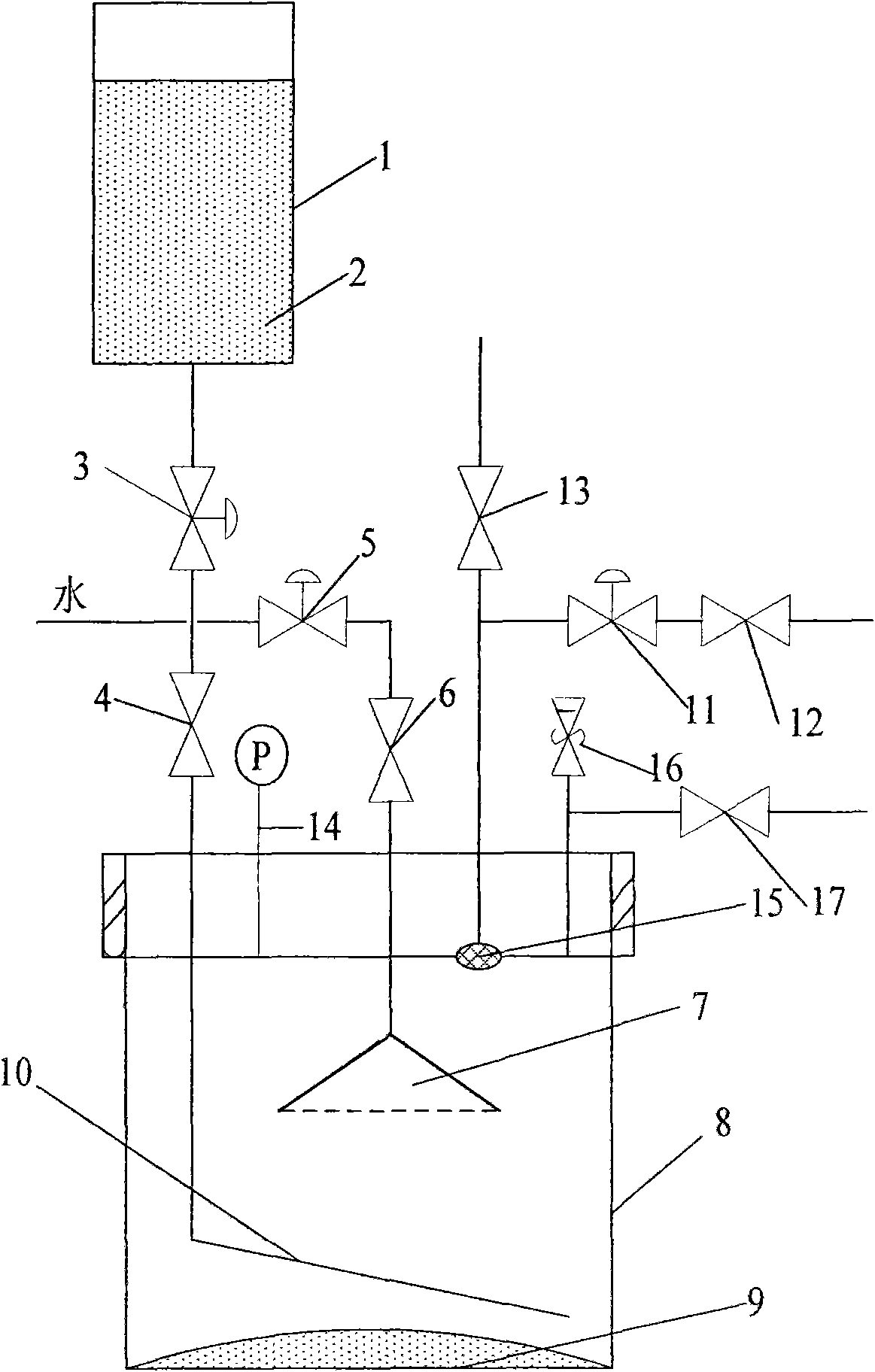

[0044] Add 368g of aluminum powder into the aluminum powder container, adjust the opening of the first flow control valve 4 to control the flow of aluminum powder to about 6.2g / min, and the opening of the second flow control valve 6 to make the flow of water about 12.3ml / min min, adjust the opening degree of the third flow control valve 12 so that the flow rate of hydrogen is about 7.6 L / min. When the monitored power system is powered off, the first solenoid valve 3, the second solenoid valve 5 and the third solenoid valve 11 are automatically opened due to the monitored power interruption, and aluminum powder and water enter the reactor to produce hydrogen. Hydrogen flows to the negative electrode of the fuel cell through the third solenoid valve 11 and the third flow control valve 12, and can supply hydrogen for a 500W fuel cell for about 1 hour.

Embodiment 2

[0046] Add 740g of aluminum powder into the aluminum powder container, adjust the opening of the first flow control valve 4 to control the flow of aluminum powder to about 12.3g / min, adjust the opening of the second flow control valve 6 to make the flow of water about 24.5ml / min, adjust the opening of the third flow control valve 12 so that the flow of hydrogen is about 15.2L / min. When the monitored power system is powered off, the first solenoid valve 3, the second solenoid valve 5 and the third solenoid valve 11 are automatically opened due to the monitored power interruption, and aluminum powder and water enter the reactor to produce hydrogen. Hydrogen flows to the negative electrode of the fuel cell through the third solenoid valve 11 and the third flow control valve 12, and can supply hydrogen for a 1000W fuel cell for about 1 hour.

Embodiment 3

[0048] Add 1.1kg of aluminum powder into the aluminum powder container, adjust the opening of the first flow control valve 4 to control the flow of aluminum powder to about 18.3g / min, adjust the opening of the second flow control valve 6 to make the water flow about 36.6ml / min, adjust the opening of the third flow control valve 12 to make the flow of hydrogen about 22.8L / min. When the monitored power system is powered off, the first solenoid valve 3, the second solenoid valve 5 and the third solenoid valve 11 are automatically opened due to the monitored power interruption, and aluminum powder and water enter the reactor to produce hydrogen. Hydrogen flows to the negative electrode of the fuel cell through the third solenoid valve 11 and the third flow control valve 12, and can supply hydrogen for a 1500W fuel cell for about 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com