Electronegative one-component developing agent

A one-component, developer technology, used in developer, electrography, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The weight percentage of each component is: polyester resin: 30%, magnetic powder: 55%, polypropylene wax: 8%, charge regulator: 3%, external additive: 4%. Among them, the polyester resin is composed of 20% polyester resin with a softening point of 160-180°C and 10% polyester resin with a softening point of 90-110°C; polypropylene wax is composed of 6% polyester resin with a softening point of 148°C. It is composed of propylene wax and 2% polypropylene wax with a softening point of 148°C; the external additive is composed of 0.67% of traditional external additive and 0.33% of ultra-fine titanium dioxide.

[0012] The preparation process is as follows: firstly weigh two kinds of resins, two kinds of polypropylene waxes, traditional additives and ultrafine titanium dioxide according to the above proportions, fully mix them in different containers respectively, and set them aside for later use. After weighing and mixing the resin mixture and magnetic powder, use special hi...

Embodiment 2

[0016] The weight percent of each component is: polyester resin: 65%, magnetic powder: 30%, polypropylene wax: 3%, charge regulator: 0.3%, external additive: 1.7%. Among them, the polyester resin is composed of 37% polyester resin with a softening point of 160-180°C and 28% polyester resin with a softening point of 90-110°C; polypropylene wax is composed of 2% polyester resin with a softening point of 148°C. It is composed of propylene wax and 1% polypropylene wax with a softening point of 148°C; the external additive is composed of 1.2% traditional external additive and 0.5% ultrafine titanium dioxide. Its preparation process is the same as embodiment one.

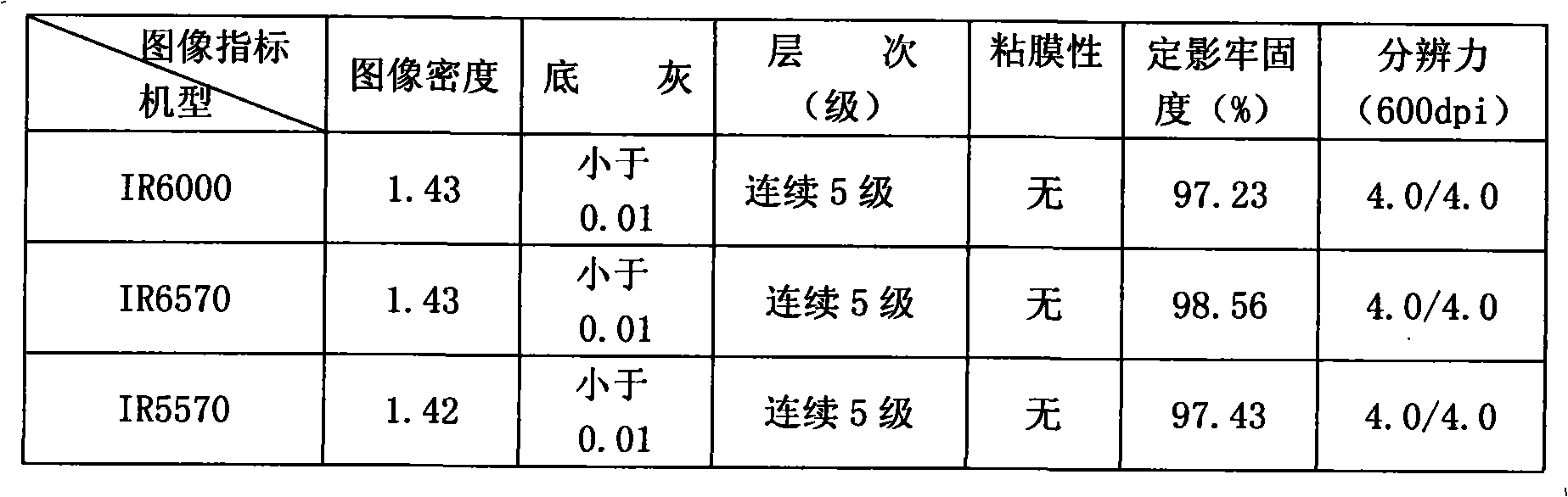

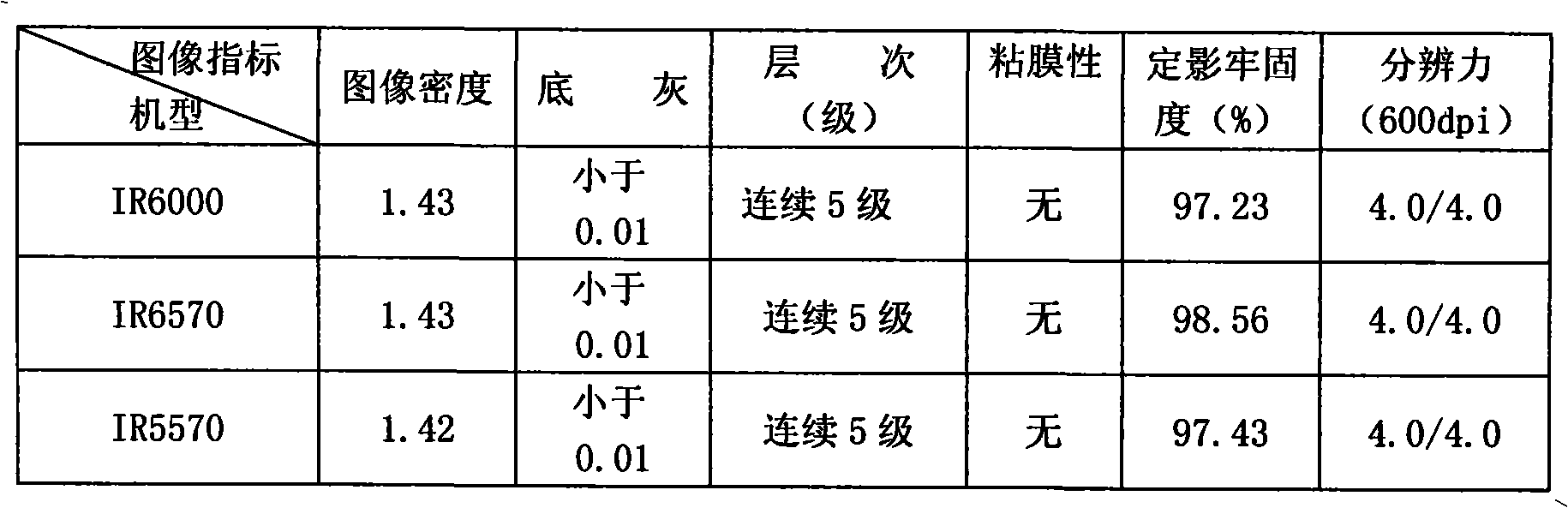

[0017] The charged amount of the produced negative one-component developer is -16.34 μc / g, and the degree of agglomeration is 23.78%. The application situation on the new high-speed digital copier is as follows:

[0018]

Embodiment 3

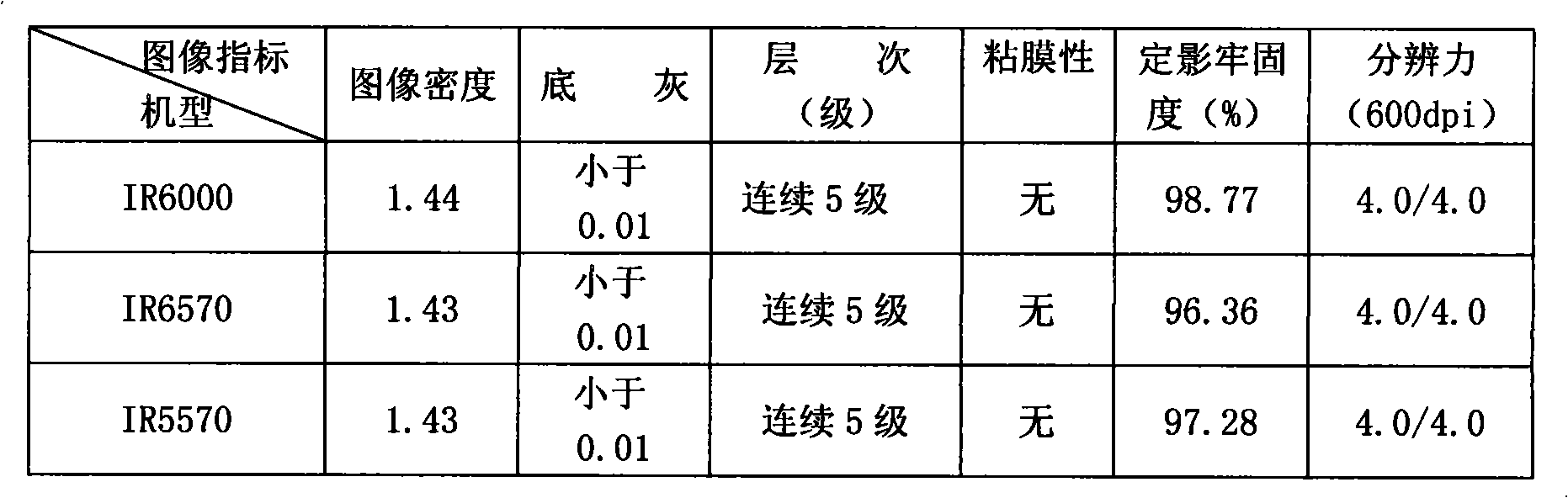

[0020] The weight percent of each component is: polyester resin: 46.5%, magnetic powder: 45%, polypropylene wax: 5%, charge regulator: 1.5%, external additive: 2%. Among them, the polyester resin is composed of 30% polyester resin with a softening point of 160-180°C and 16.5% polyester resin with a softening point of 90-110°C; polypropylene wax is composed of 3% polyester resin with a softening point of 148°C. It is composed of propylene wax and 2% polypropylene wax with a softening point of 148°C; the external additive is composed of 1.5% traditional external additive and 0.5% ultrafine titanium dioxide. Its preparation process is the same as embodiment one.

[0021] The weight percentage of each component is: (160~180) ℃ high softening point polyester resin 32%, (90~110) ℃ low softening point polyester resin 16%, magnetic powder: 45%, 148 ℃ softening point 2.5% polypropylene wax, 1.0% polypropylene wax with a softening point of 161°C, 2.3% charge regulator, 0.67% traditiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com