Coke oven raw gas rising pipe waste heat recovery device

A waste heat recovery device and raw gas technology, applied in the field of waste heat recovery device, coke oven waste gas riser waste heat recovery device, can solve the problems of safety accidents, steam drum water leakage, jacket water jacket leakage, etc., to ensure The effects of safe operation, increased steam production pressure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

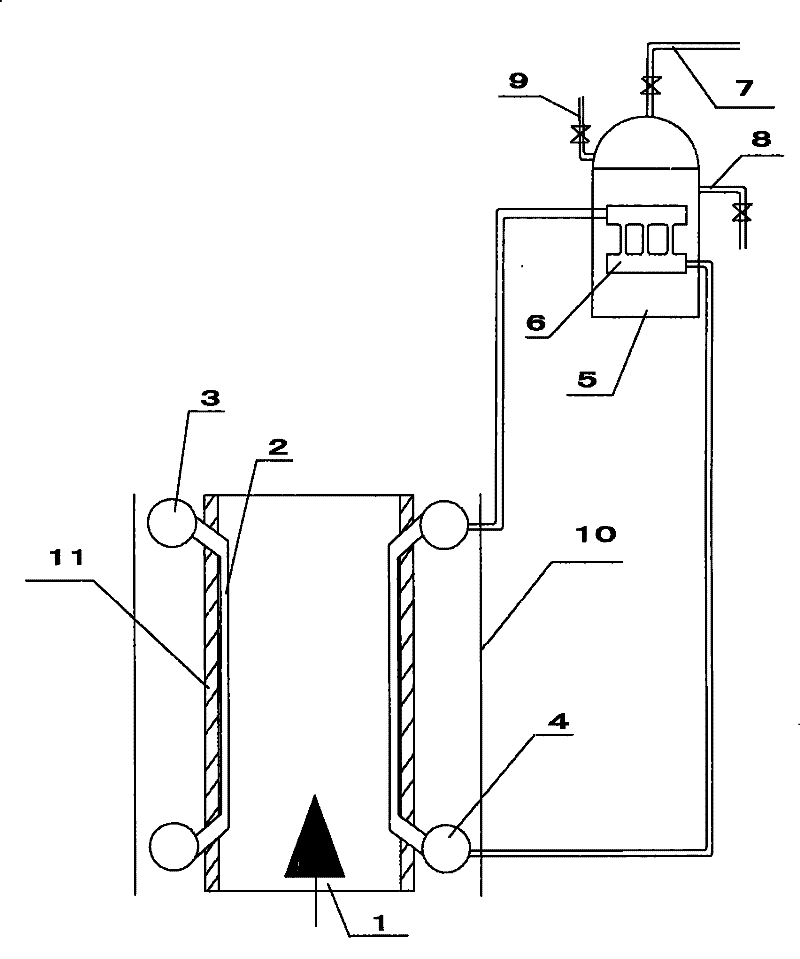

[0012] The coke oven raw gas rising pipe waste heat recovery device of this embodiment includes an upper header 3 and a lower header 4 surrounding the coke oven raw gas rising pipe 1 as the inner wall of the refractory brick layer 11 . The upper header 3 and the lower header 4 lead inwardly respectively a group of separate heat pipe heat-absorbing ends 2 connecting the upper and lower headers. The upper header 3 is connected, and the lower end is inclined downward through the inner wall of the coke oven raw gas riser pipe to communicate with the lower header 4, so that a smooth passage is formed between them. At the same time, the upper part of the upper header 3 and the lower part of the lower header 4 communicate upwards with the upper part and the lower part of the heat release end 6 of the separated heat pipe respectively through the connection pipeline of the outgoing riser shell 10, and the heat release end 6 of the separate heat pipe is located at Inside the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com