Full-automatic intelligent vacuum freeze dryer

A vacuum freeze-drying and intelligent technology, applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of inability to automatically provide, artificial calculation errors, and drug scrapping, etc., to save production costs and save Water consumption, ensure the effect of rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

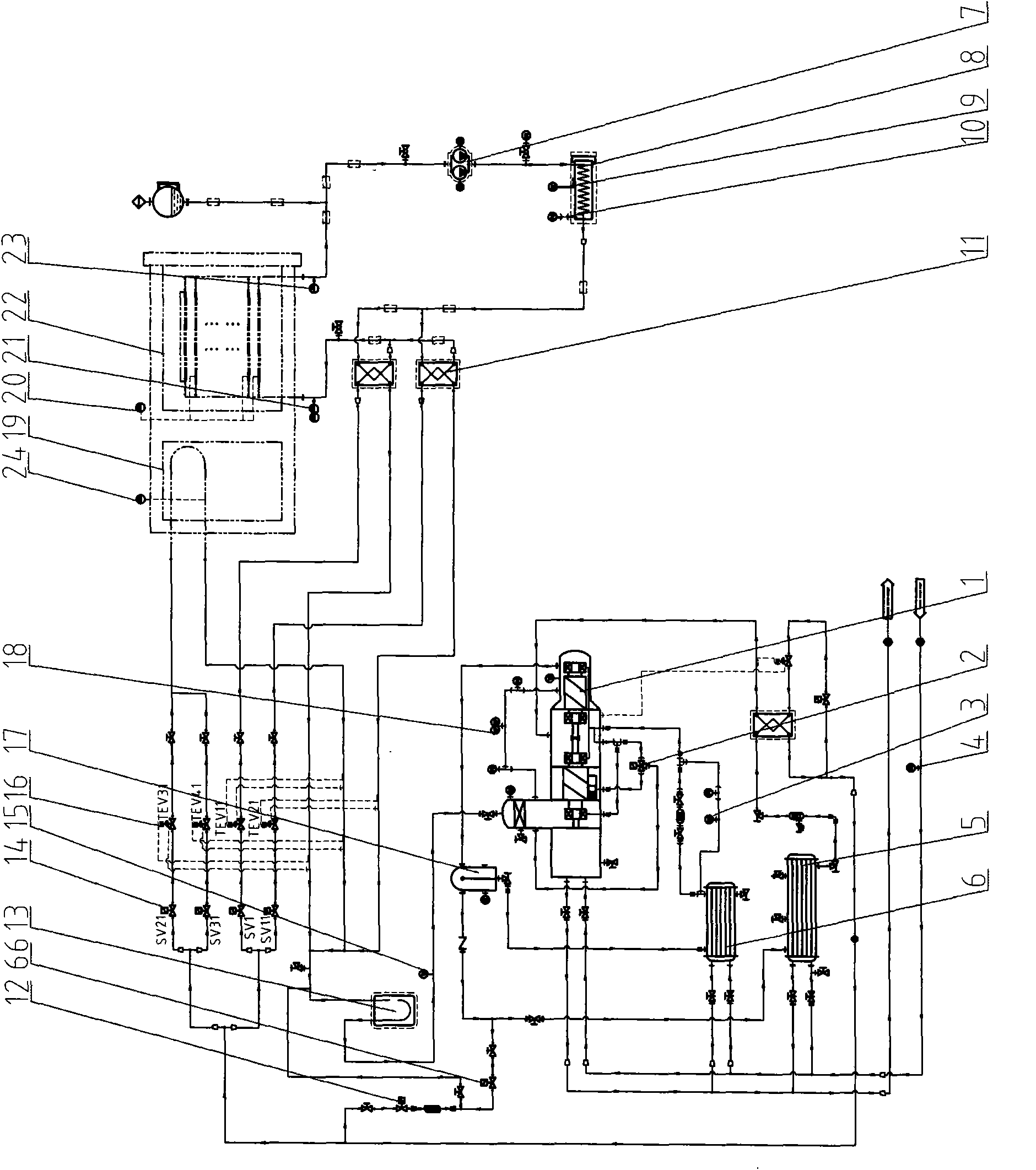

[0032] Such as figure 1 Shown is a schematic diagram of the vacuum freeze drying part of a fully automatic intelligent vacuum freeze dryer provided by the present invention, including a cold trap 19, a front box 22, and a compressor 1. The cold trap 19 and the front box 22 are respectively provided There are cold trap coil temperature probe 24 and product temperature probe 20. The heat conduction oil outlet temperature probe 23 and the heat conduction oil inlet temperature probe 21 are respectively provided on the heat conduction oil outlet end and heat conduction oil inlet end of the front box 22. The outlet end of the heat transfer oil is connected with the dual-motor circulating pump 7 and the electric heater 8. The electric heater 8 is provided with a temperature controller 9 and a pressure relay 10, and the outlet end of the electric heater 8 is connected with a plate heat exchanger 11, The outlet end of the plate heat exchanger 11 is connected to the heat transfer oil inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com