Non-equilibrium magnetron-sputtering rare-earth multivariate graphite composite film and preparation method thereof

A magnetron sputtering and multi-component compounding technology, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating technology, etc., can solve the problems of poor thermal stability and electrochemical corrosion resistance, and achieve electrochemical resistance Improved corrosion resistance and wear resistance, improved adhesion to base film, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

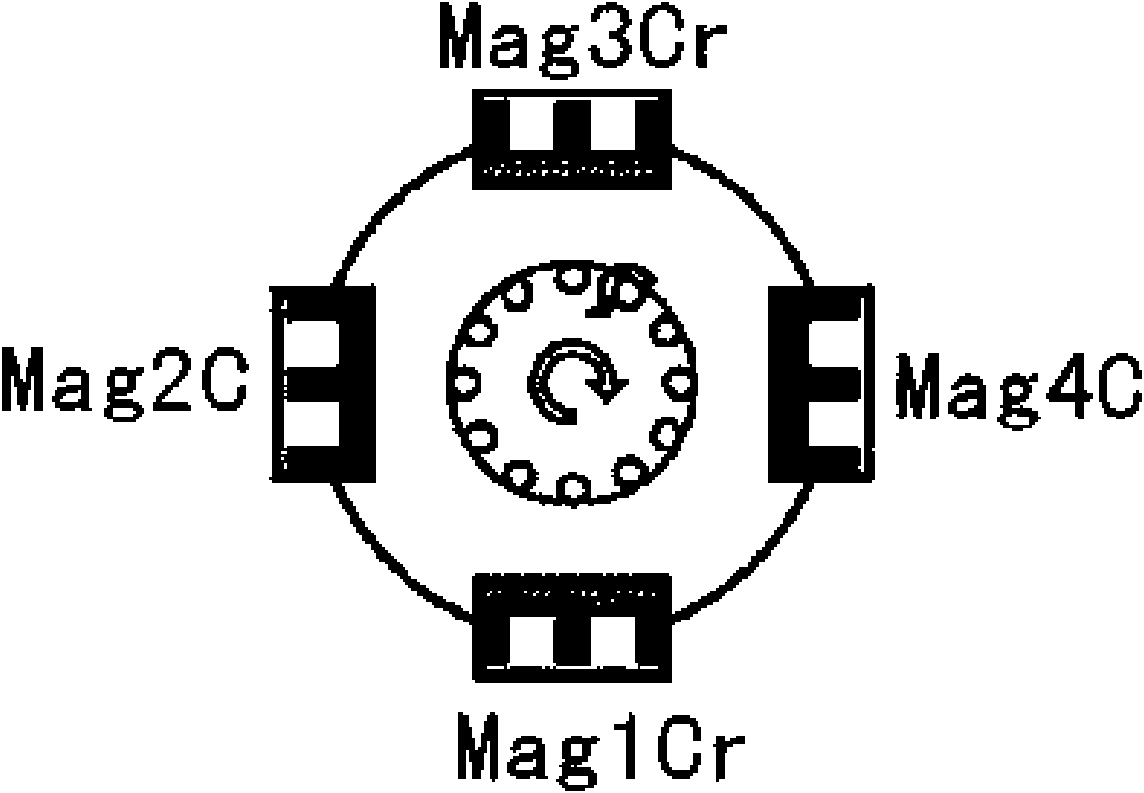

Method used

Image

Examples

Embodiment 1

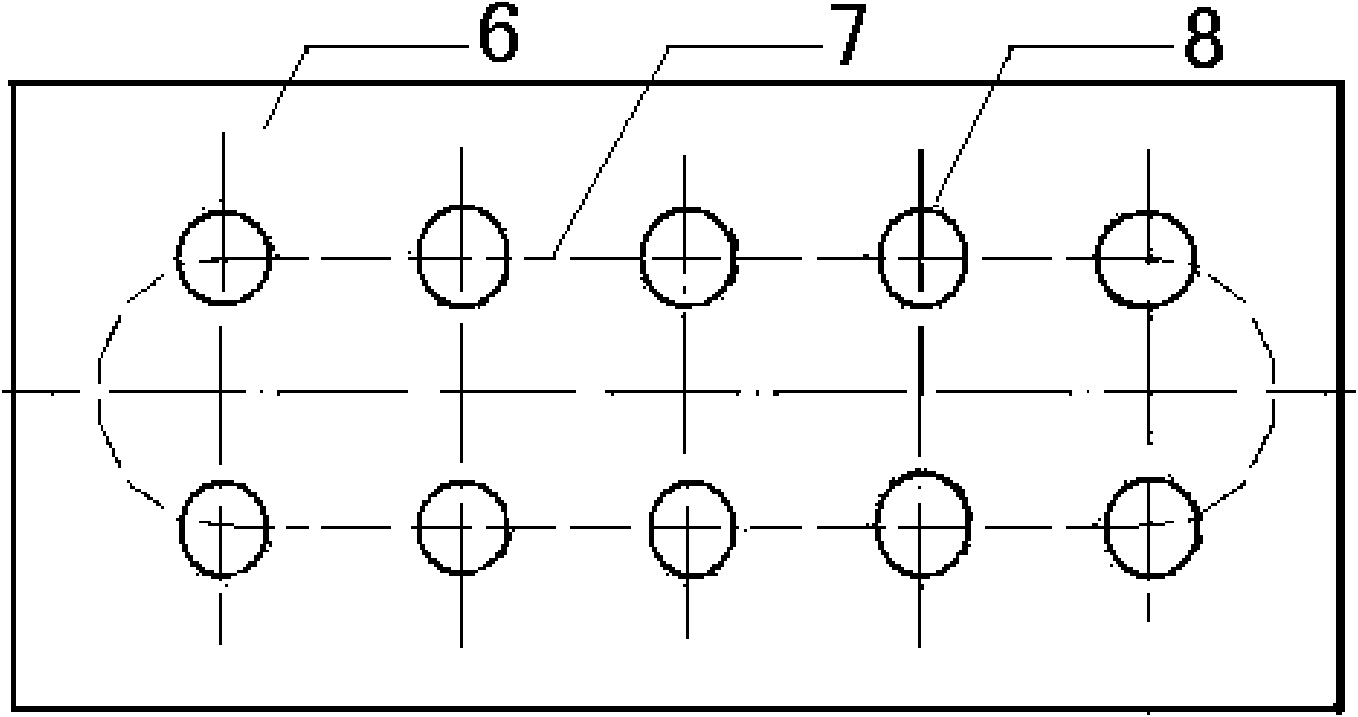

[0092] Determine the composition of the composite film, wherein the Cr / RE transition layer 3 is composed of: Ce: 0.1%, Cr: 99.9% according to the mass percentage, and the C / Cr-RE multi-component composite layer 5 is composed of Cr: 3% according to the mass percentage , Ce: 0.3%, Zr: 0.3%, C: 96.4%.

[0093] Calculate the number of rare earth Ce inserts embedded on the high-purity chromium target, known S = 650cm 2 , α Ce / Cr =0.51,β Ce / Cr = 0.95, γ Ce =99.9%, A=0.1%, get S by formula (1) 1 =1.34cm 2 , when the insert diameter is Φ10mm, S 2 =0.785cm 2 , get n from formula (2) 1 = S 1 / S 2 = 1.7, rounded to 2 Ce inserts;

[0094] Calculate the number of rare earth Ce inlays embedded on the high-purity carbon target, and it is known that S=650cm 2 , α Ce / C =5,β Ce / C = 2.99, gamma Ce =99.9%, A=0.3%, get S by formula (1) 1 =0.13cm 2 , when the insert diameter is Φ4mm S 2 =0.126cm 2 , get n from formula (2) 2 = S 1 / S 2 = 1.03, rounded to 1 Ce insert;

[0095] Cal...

Embodiment 2

[0099] Determine the composition of the composite film, wherein, the Cr / RE transition layer 3 is composed of: Ce: 0.5%, Cr: 99.5%, and the C / Cr-Ce multi-component composite layer 5 is composed of: Cr: 15% according to the mass percentage , Ce: 5%, :Ta: 5%, C: 75%.

[0100] Calculate the number of rare earth Ce inserts embedded on the high-purity chromium target, known S = 650cm 2 , α Ce / Cr =0.51,β Ce / Cr = 0.95, γ Ce =99.9%, A=0.5%, get S by formula (1) 1 =6.72cm 2 , when the insert diameter is Φ17mm, S 2 =2.27cm 2 , get n from formula (2) 1 = S 1 / S 2 =2.96, rounded to 3 Ce inserts;

[0101] Calculate the number of rare earth Ce inlays embedded on the high-purity carbon target, and it is known that S=650cm 2 , α Ce / C =5,β Ce / C = 2.99, gamma Ce =99.9%, A=5%, get S by formula (1) 1 =2.18cm 2 , when the insert diameter is Φ8mm, S 2 =0.50cm 2 , get n from formula (2) 2 = S 1 / S 2 =4.36, rounded to 4 Ce inserts;

[0102] Calculate the number of metal Zr insert...

Embodiment 3

[0106] Determine the composition of the composite film, wherein the Cr / RE transition layer 3 is composed of: Ce: 1%, Cr: 99% according to the mass percentage, and the C / Cr-Ce multi-component composite layer 5 is composed of: Cr: 10% according to the mass percentage , Ce: 10%, Zr: 10%, C: 70%.

[0107] Calculate the number of rare earth Ce inserts embedded on the high-purity chromium target, known S = 650cm 2 , gamma Ce = 99.9%, α Ce / Cr =0.51,β Ce / Cr =0.95, A=0.5%, get S by formula (1) 1 =13.43cm 2 , when the insert diameter is Φ17mm, S 2 =2.27cm 2 , get n from formula (2) 1 = S 1 / S 2 =5.92, rounded to 6 Ce inserts;

[0108] Calculate the number of rare earth Ce inlays embedded on the high-purity carbon target, and it is known that S=650cm 2 , gamma Ce = 99.9%, α Ce / C =5,β Ce / C =2.99, A=10%, get S by formula (1) 1 =4.35cm 2 , when the insert diameter is Φ8mm, S 2 =0.50cm 2 , get n from formula (2) 2 = S 1 / S 2 =8.70, rounded to 8 Ce inserts;

[0109] Calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com