Bacillus and application thereof

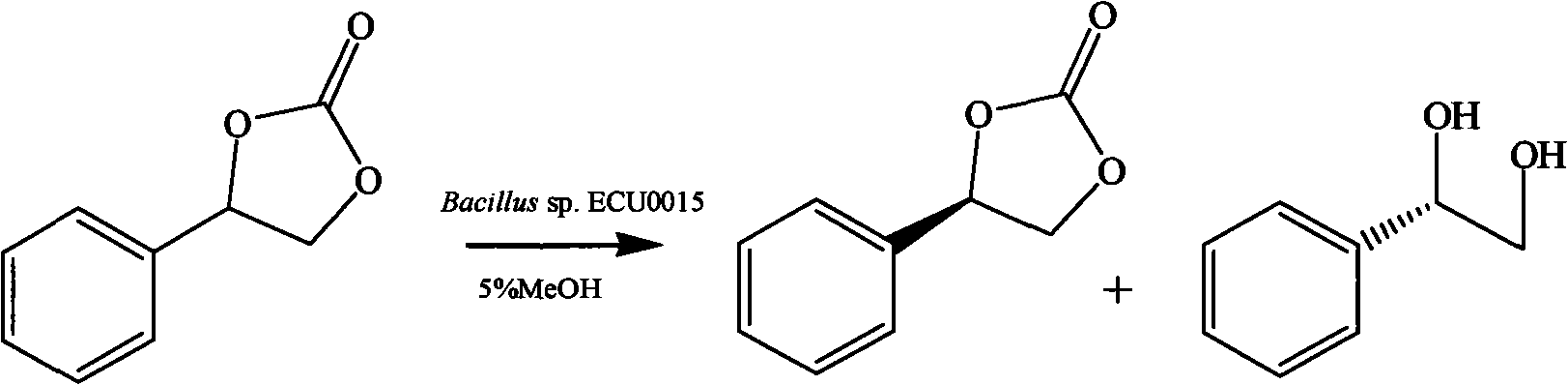

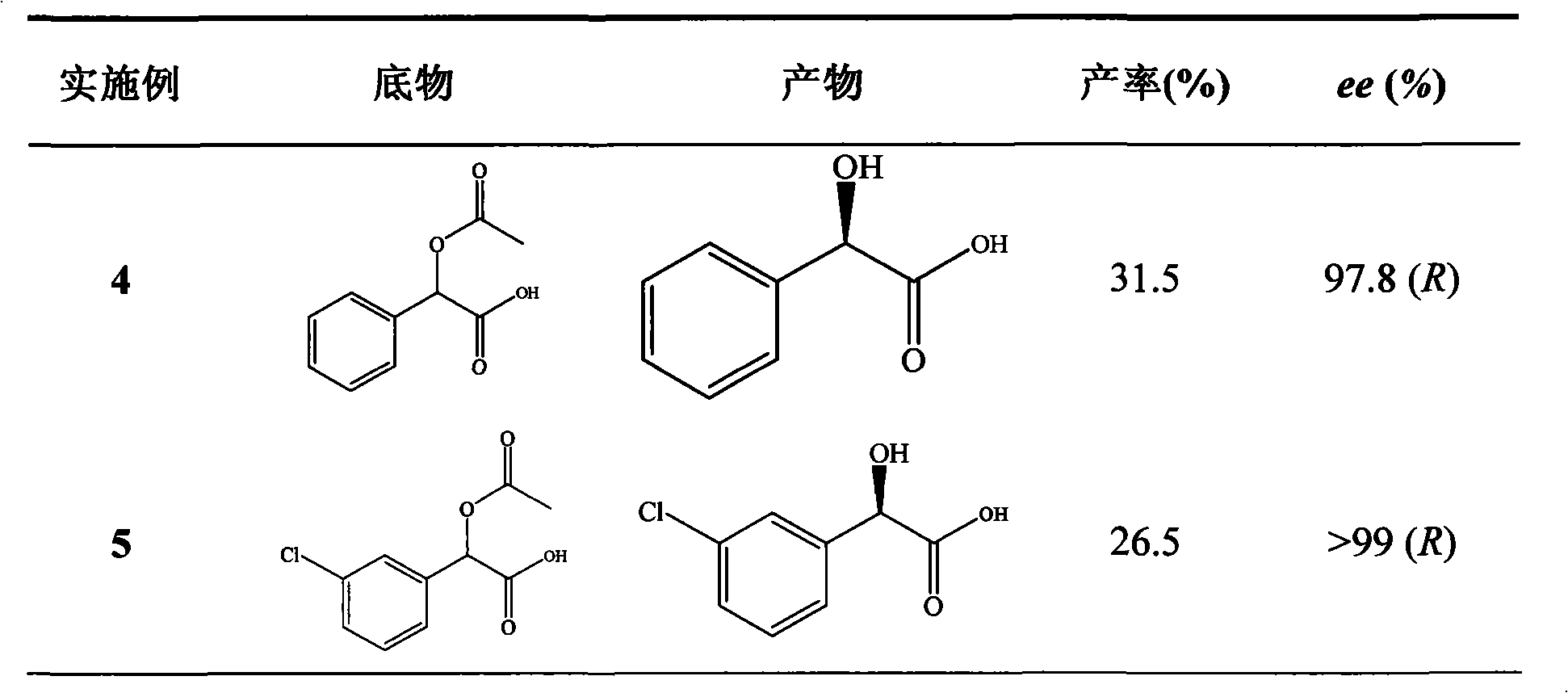

A technology of Bacillus and Bacillus, applied in the field of biochemical industry, can solve the problem of less hydrolysis and splitting of acetylmandelic acid, and achieve good industrial application development prospects, mild reaction conditions, and wide substrate adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Screening of bacterial strains

[0032] To determine the screening of microorganisms from soil and other environments, the enrichment medium is first prepared, and the composition of the medium is: (NH 4 ) 2 SO 4 1.0g / L, KH 2 PO 4 3.0g / L, K 2 HPO 4 6.0g / L, MgSO 4 0.5g / L, CaCl 2 0.05g / L; another rich medium was prepared, consisting of: glucose (or glycerol) 15g / L, beef extract 5g / L, peptone 5g / L, KH 2 PO 4 1.0g / L, Na 2 HPO 4 1.0g / L, MgSO 40.5g / L, pH 7.0. Take a small amount of soil samples from different sources and suspend them in 2ml enrichment medium, add phenylethylene glycol cyclocarbonate or diethyl carbonate (concentration: 0.2-1g / L) as the only carbon source, at 25-40℃ 1. Enrichment culture under 200rpm shaking condition for 1 to 2 days, transfer to fresh medium after the microorganisms grow up, and continue to culture for 1 to 2 days. After the enrichment culture, samples were taken for thin-plate chromatography, and the presence o...

Embodiment 2

[0034] Example 2 Culture of microorganisms

[0035] Medium formula: glycerol 15g / L, beef extract 8g / L, peptone 5g / L, KH 2 PO 4 1.0g / L, Na 2 HPO 4 1.0g / L, MgSO 4 0.5g / L, pH 7.0. High temperature sterilization at 121℃ for 20min.

[0036] Take the Bacillus slant preserved at 4°C, pick a ring and inoculate it into a 250ml shake flask containing 50ml of culture medium. At 30°C, cultured on a shaker at 160rpm for 12h, transferred to a 500ml shaker flask containing 100ml of medium at a 5% (v / v) inoculum size, continued to cultivate at 30°C and 160rpm for 36h, and harvested cells by centrifugation. The measured enzyme activity of the fermentation broth is about 5.08U / L, the cell concentration is about 25g (wet weight) / L, and the enzyme activity per wet cell is 0.20U / g wet cell.

[0037] The whole cell viability is defined as: under the conditions of 30°C, pH 7.3, and substrate concentration of 10 mM, the amount of enzyme required to catalyze phenylethylene glycol cyclocarbona...

Embodiment 3

[0038] Example 3 Preparation of (S)-(-)-phenylethylene glycol by resting cells

[0039] Suspend 12 g of the resting cells of Bacillus sp. ECU0015 obtained by centrifugation in 100 ml of phosphate buffer (100 mM, pH 7.3), add the substrate phenylethylene glycol cyclocarbonate to make the final concentration 10 mM, and incubate at 30 ° C and After shaking and reacting on a constant temperature shaker at 160 rpm for 24 hours, the reaction solution was centrifuged at 12,000×g for 10 minutes to remove cells. Add NaCl to the supernatant to saturation, extract with 50 ml of anhydrous ether, and repeat three times. The cells obtained by centrifugation were immersed in 20 ml of anhydrous ether, and repeated twice. The two parts of ether solutions were combined, and washed twice with saturated NaCl solution, 10 ml each time. The obtained diethyl ether extract was dried overnight with 10% (w / v) anhydrous sodium sulfate, and the diethyl ether was removed by rotary evaporation to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com