Wellbore Stabilizer

A wellbore stabilizer and stabilizer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as loss of enterprises and countries, difficulty in running casing, environmental pollution, etc., to reduce drilling costs and shorten the The drilling cycle and market prospects are promising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment.

[0017] The optimal weight percentage of each component of well wall stabilizer is:

[0018] Sodium bentonite 30%-50%

[0019] Hydrolyzed polyacrylonitrile ammonium salt 20%-40%

[0020] Activated graphite fine powder 20%-40%.

[0021] The bentonite is selected to comply with SY5490-93 sodium bentonite for drilling fluid.

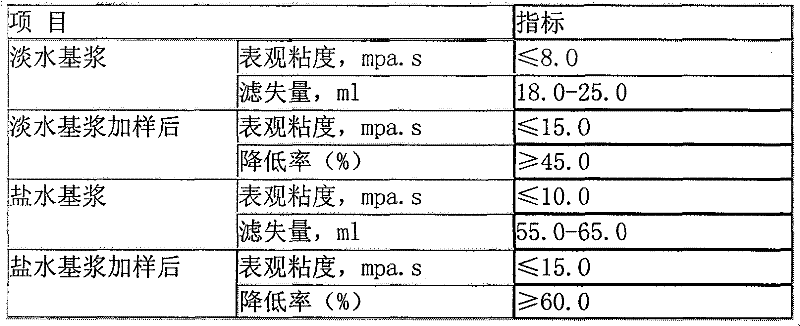

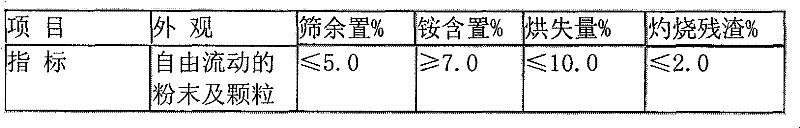

[0022] The quality inspection standard of sodium bentonite:

[0023] 1. Sensory properties: This product is a white or pink powder substance.

[0024] 2. Moisture: the moisture content shall not exceed 12.0%.

[0025] 3. Main ingredients: Bentonite contains 85-90% montmorillonite, 50-75% silicon oxide, 15-25% lead oxide, and a specific gravity of 2.4-2.8. In addition, it also contains P, KNa, Ca, Mg, Fe, Cu, Mn, Cr, Si, Ni, Ti, V and other constant and trace elements.

[0026] 4. The particle size is 100-120 mesh.

[0027] Hydrolyzed polyacrylonitrile ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com