Double-slip hydraulic anchoring sealing device for window sidetrack drilling

A technology of window sidetracking and isolation device, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well components, etc., and can solve the problems of difficult operation safety, low reliability, displacement of anchoring tools, etc. problems, to achieve the effect of improving operation efficiency, increasing production efficiency and shortening drilling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

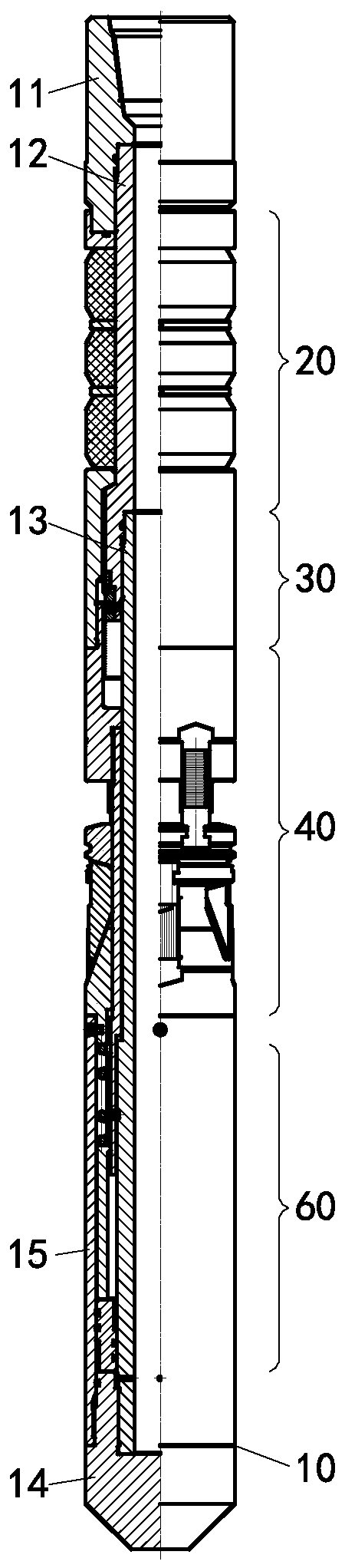

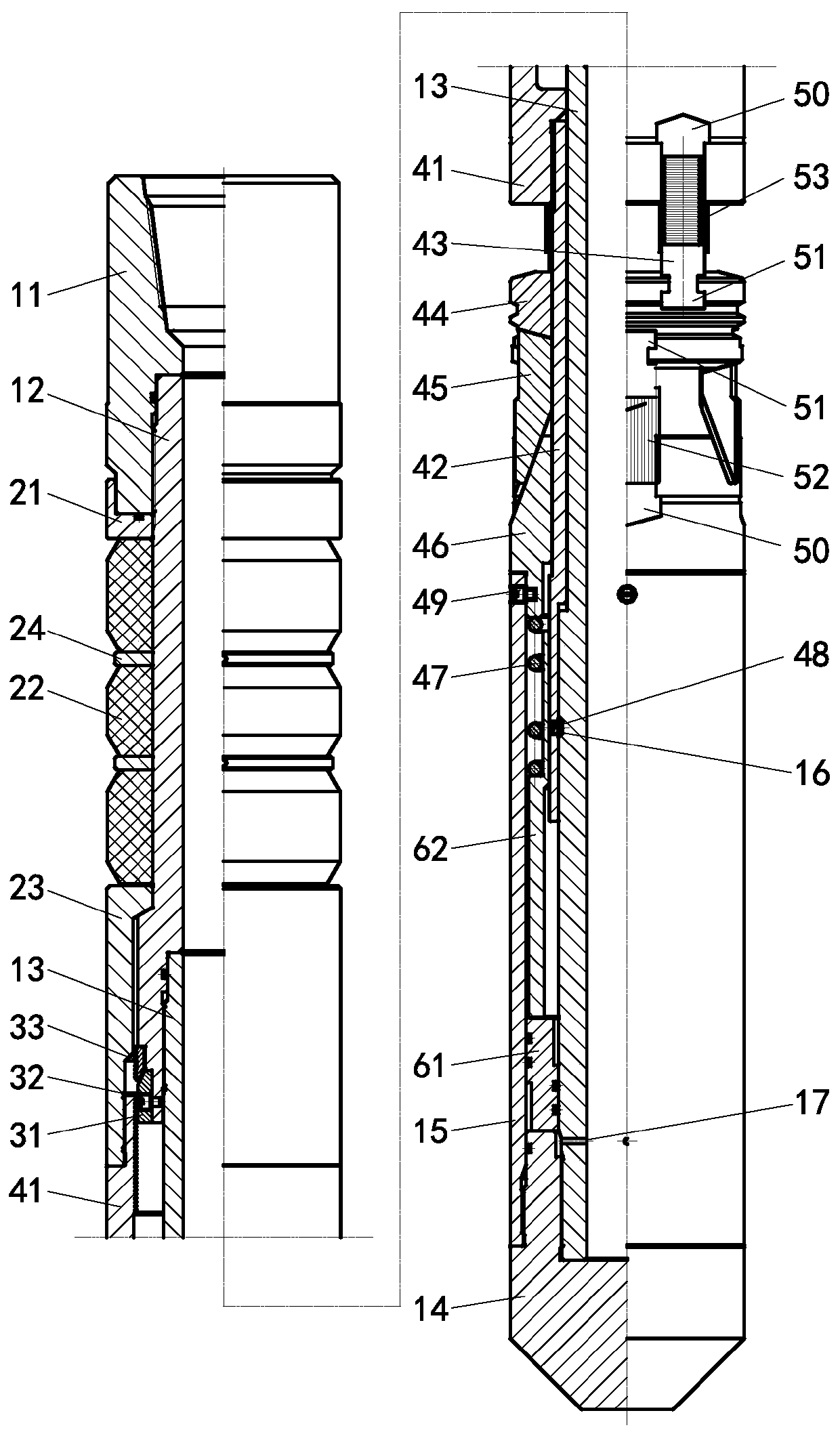

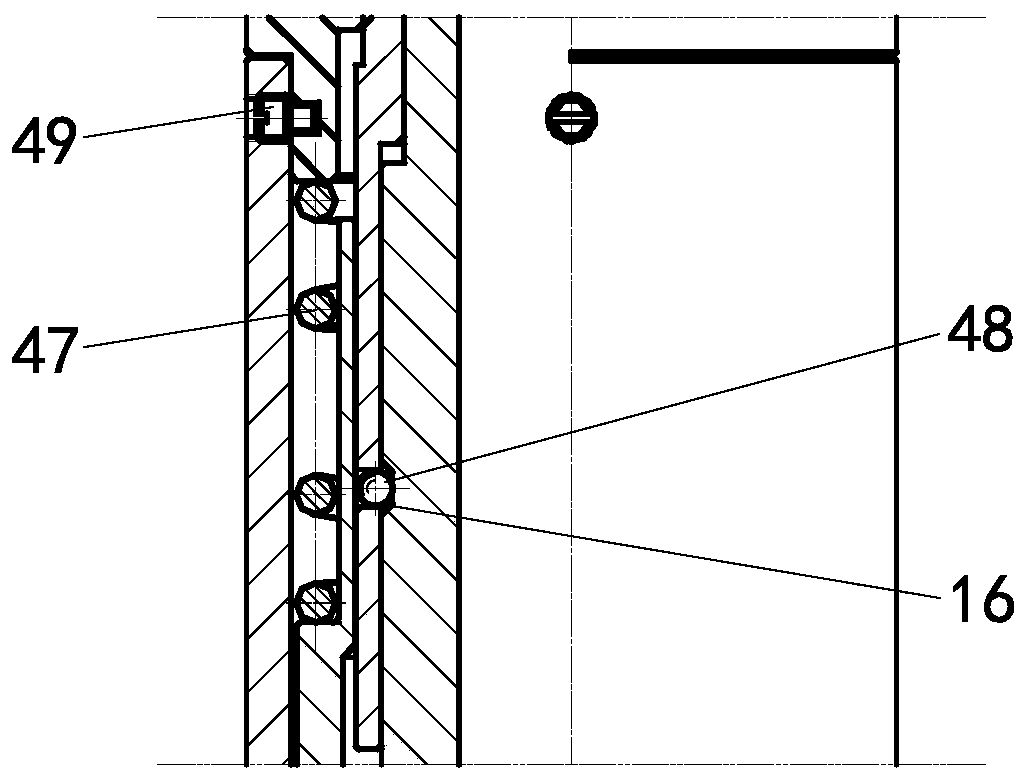

[0024] The device in this example consists of a suspension unit 10 , a sealing unit 20 , a locking and unsealing recovery unit 30 , a slip anchoring unit 40 , and a force transmission unit 60 . The suspension unit 10 includes an upper joint 11 , an upper core tube 12 , a lower core tube 13 , a lower joint 14 and a cylinder liner 15 . The sealing unit 20 is composed of a core tube lock cap 21 , a rubber tube 22 , a connecting sleeve 23 and a spacer ring 24 . The locking and unsealing recovery unit 30 includes a locking taper sleeve 31 , unsealing shears 32 and a locking ring 33 . The slip anchoring unit 40 includes an upper slip seat 41 , a locking sleeve 42 , an upper slip 43 , a slip base 44 , a lower slip 45 , a lower slip seat 46 and a spring 47 . The force transmission unit 60 is composed of a piston 61 and a slip pre-pushing sleeve 62 .

[0025] Eight steel balls 48 are installed along the circumference between the lower core tube 13 in the suspension unit 10 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com