Protective coating for aerogenerator vanes and preparation method thereof

A technology for wind turbines and protective coatings, applied in wind turbine components, wind engines, wind power generation, etc., to achieve the effects of outstanding acid and alkali resistance, salt spray resistance, excellent wear resistance, and low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

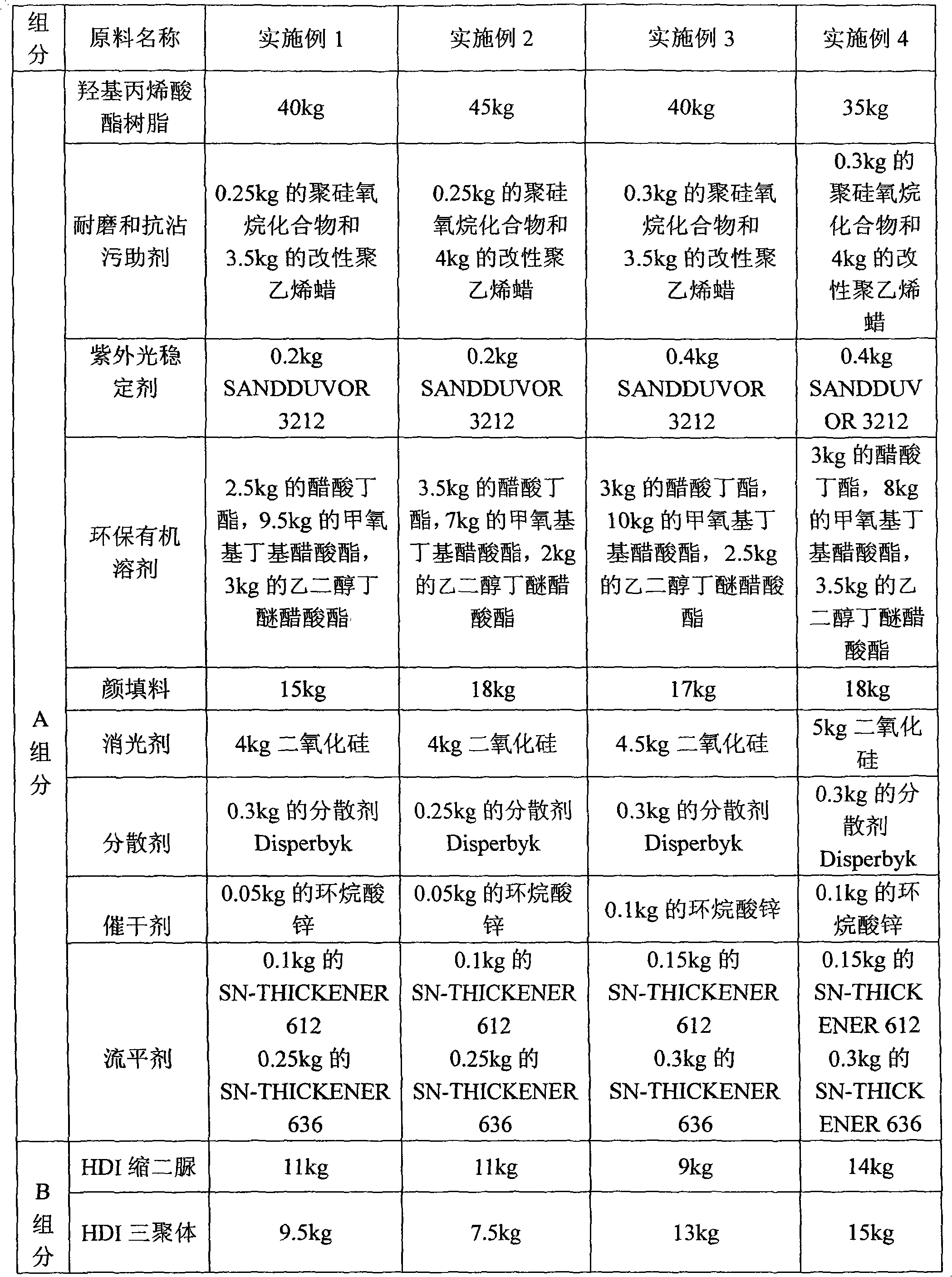

[0050] The wind power generator blade protective coating of the present embodiment comprises: described A component contains the hydroxyacrylate resin of 40kg, the polysiloxane compound of 0.25kg and the modified polyethylene wax composition of 3.5kg Contamination aid, 0.2kg Klein company's ultraviolet light stabilizer SANDDUVOR 3212 composed of a compound of aniline oxalic acid ultraviolet light absorber and hindered amine light stabilizer, composed of 2.5kg of butyl acetate, 9.5kg of Environmentally friendly organic solvent composed of methoxybutyl acetate and 3kg of ethylene glycol butyl ether acetate, 15kg of pigments and fillers, 4kg of silica matting agent, 0.3kg of polyamic acid and alkanolamine compound produced by German BYK chemical company Dispersing agent Disperbyk, 0.05kg of zinc naphthenate as drier, 0.1kg of polyurethane modified polyether SN-THICKENER 612 produced by Japan Nopco and 0.25kg of modified polyether produced by Japan Nopco A leveling agent made by m...

Embodiment 2~ Embodiment 4

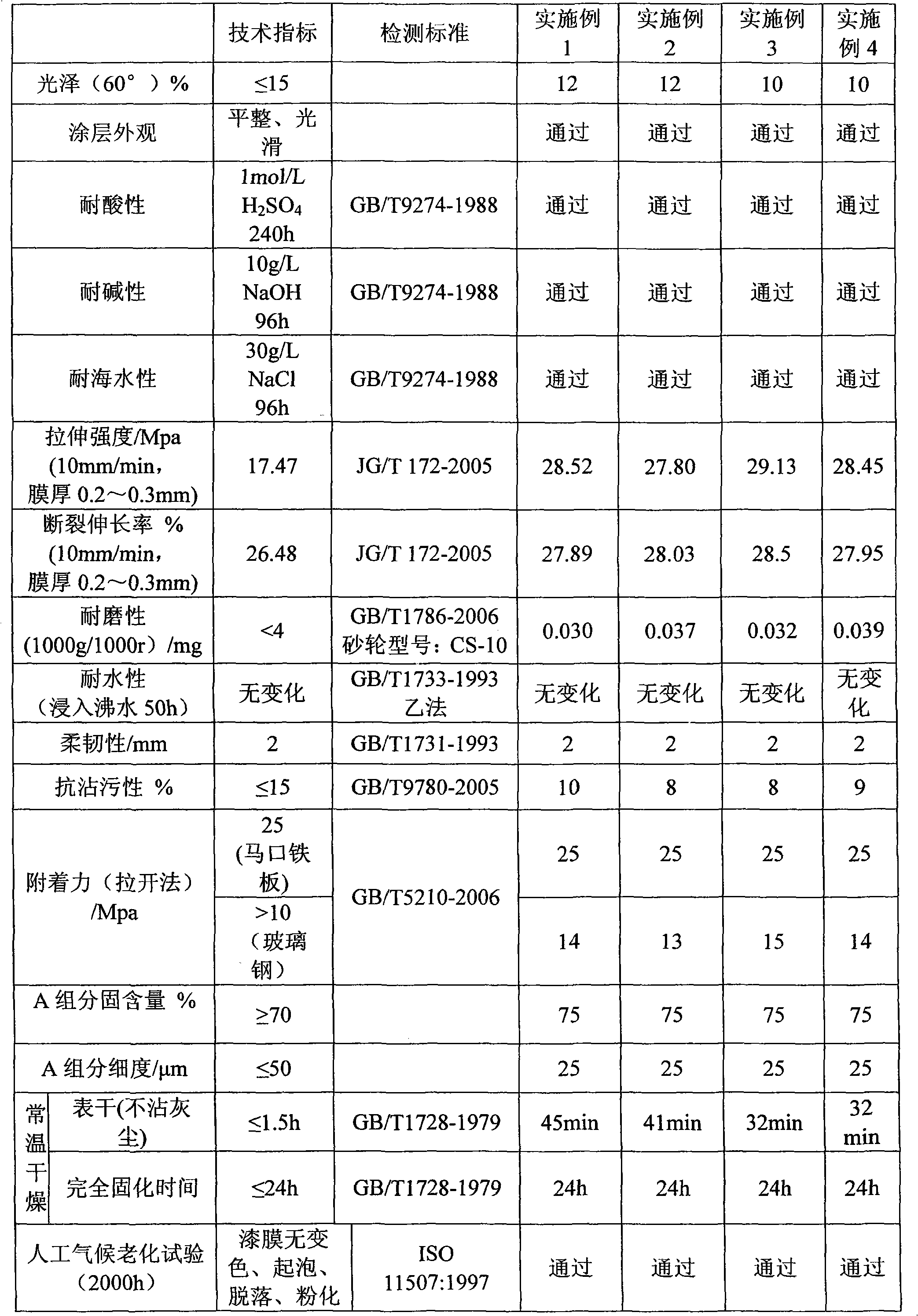

[0054] The components of the protective coatings for wind power generator blades in each embodiment are shown in Table 1, and the preparation method of each embodiment is basically the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com