Method for preparing MQ silicon resin by organic acid catalysis

A technology for MQ silicone resin and catalytic preparation, applied in the field of organic acid catalyzed preparation of MQ silicone resin, can solve the problems of shortening the service life of packaging materials, reducing the aging resistance of packaging materials, affecting the dielectric properties of devices and equipment, etc., to increase the use of The effect of life, prolonging the use time, and improving the aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

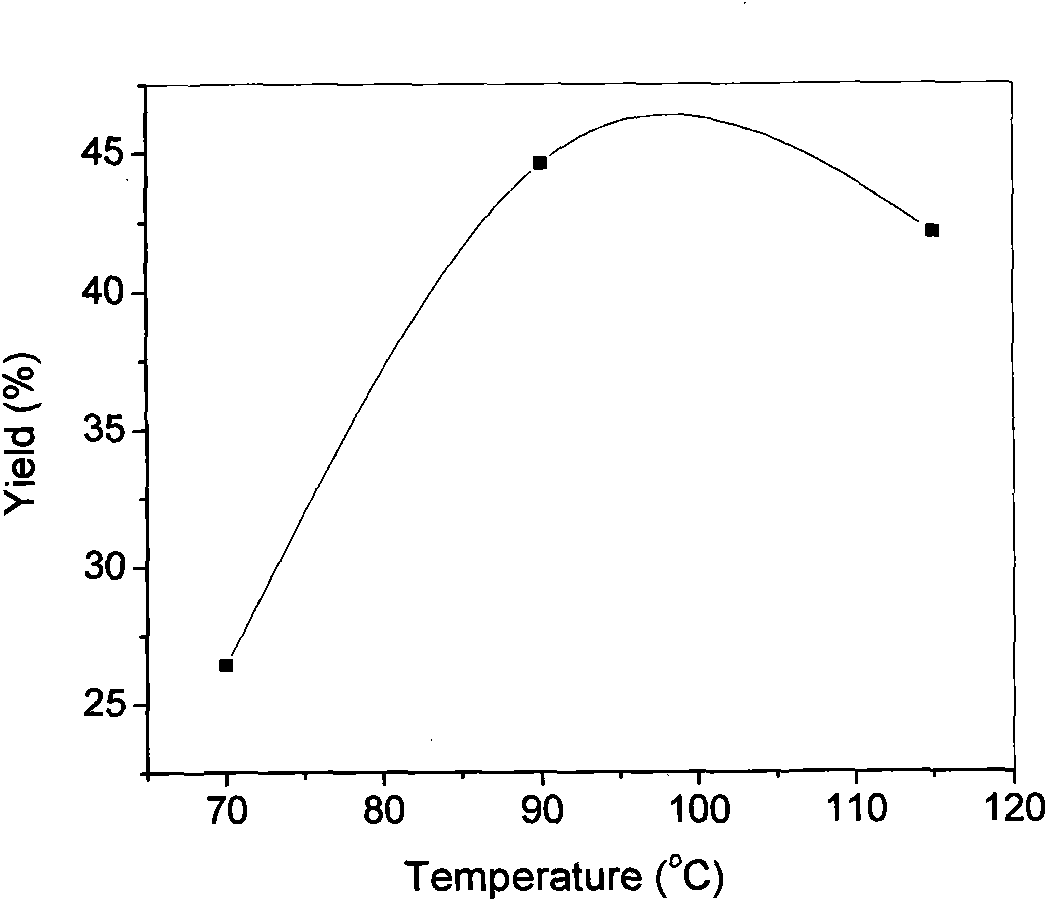

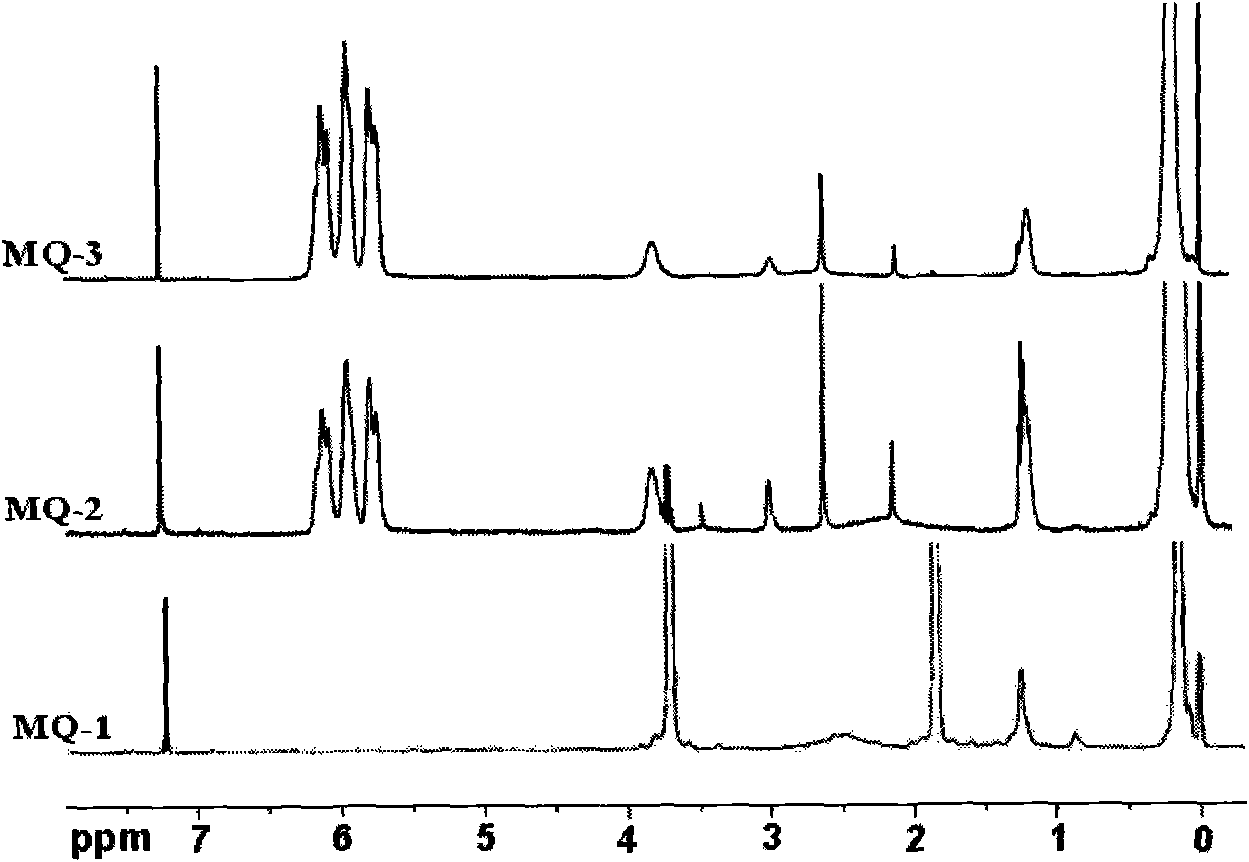

[0014] Example 1 Add 624g of tetraethyl orthosilicate and 292g of hexamethyldisiloxane into a reactor with a mechanical stirring and condensing device, slowly add 160mL of an aqueous solution containing 9.2g of p-toluenesulfonic acid, and raise the temperature to 115°C for reaction 10h. After the reaction, neutralize with a certain amount of ammonia water, add 500mL of toluene, separate the liquid and wash with water until neutral, distill toluene and low boilers under reduced pressure at 80°C, and recover them, and continue vacuuming for 1 hour to obtain solid MQ Silicone.

Embodiment 2

[0015] Example 2 Add 624g of tetraethyl orthosilicate and 292g of hexamethyldisiloxane into a reactor with a mechanical stirring and condensing device, slowly add 160mL of an aqueous solution containing 9.2g of p-toluenesulfonic acid, and raise the temperature to 90°C for reaction 10h. After the reaction, neutralize with a certain amount of ammonia water, add 500mL of toluene, separate the liquid and wash with water until neutral, distill toluene and low boilers under reduced pressure at 80°C, and recover them, and continue vacuuming for 1 hour to obtain solid MQ Silicone.

Embodiment 3

[0016] Example 3 Add 624g of tetraethyl orthosilicate, 97g of hexamethyldisiloxane and 111g of vinyl double caps into a reactor with a mechanical stirring and condensing device, slowly add 160mL of 9.2g of p-toluenesulfonic acid Aqueous solution, heated to 115 ° C hydrolysis reaction 10h. After the reaction, neutralize with a certain amount of ammonia water, add 500mL of toluene, separate the liquid and wash with water until neutral, distill toluene and low boilers under reduced pressure at 80°C, and recover them, and continue vacuuming for 1 hour to obtain solid MQ Silicone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com