Amorphous vancomycin hydrochloride as well as preparation method, application and pharmaceutical composition thereof

A vancomycin hydrochloride, non-crystallization technology, applied in the direction of drug combinations, anti-infective drugs, glycopeptide components, etc., can solve problems such as difficult to take, large capsule particles, etc., to achieve increased effective components, reduced impurities, and improved appearance and color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

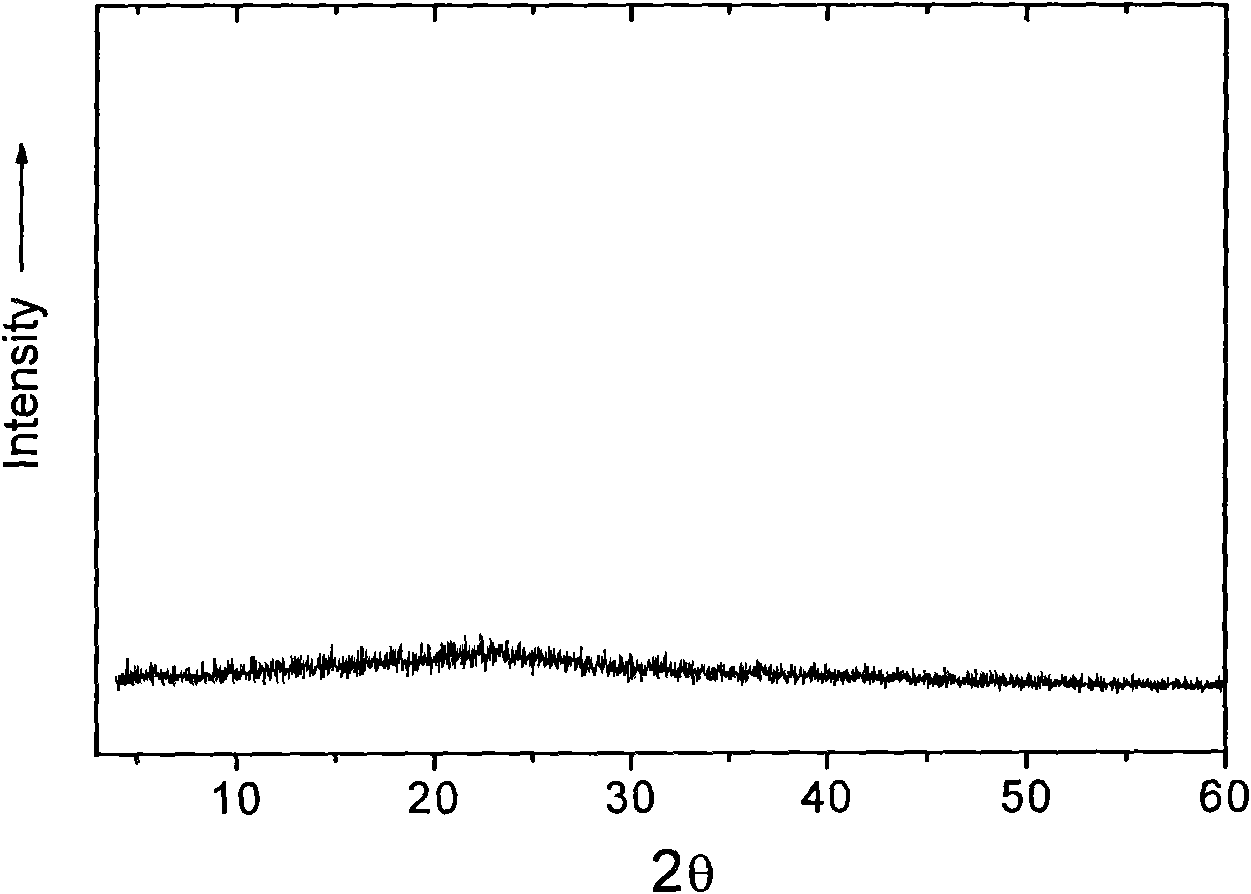

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of vancomycin crude product

[0035] The vancomycin fermentation broth is filtered under alkaline conditions, and the obtained clarified filtrate passes through the macroporous adsorption resin XAD-1600, and the vancomycin is adsorbed on the resin. After the resin is washed with water, it is eluted with an acidic aqueous solution of 40% ethanol. After elution, the eluent containing vancomycin was decolorized by adding activated carbon, and the filtrate obtained by filtering was concentrated to obtain vancomycin hydrochloride aqueous solution, and then NH 4 HCO 3 Precipitate to obtain crude vancomycin. The content of vancomycin B in crude vancomycin is 86.8%, and the potency is 599u / mg.

[0036] Take 2500g of this crude product, add 20.0L of purified water, add NaOH solution to adjust the pH to 10.0, and use 0.2M 2 25.0L of vancomycin filtrate was obtained by filtering through a ceramic membrane with a pore size of 0.5 μm, the solution ti...

Embodiment 2

[0037] Embodiment 2: the precipitation of vancomycin hydrochloride

[0038] Get 500 mL of the concentrated solution in Example 1, filter through 0.45 μm and 0.2 μm filter membranes and add 25 g NaHCO while stirring 3 , Vancomycin precipitated from it, forming a slurry, adding HCl aqueous solution to adjust the pH to 2.80, and continuing to stir for 60min to make it evenly mixed, stop stirring and let stand for 38 hours, the process temperature is controlled at 14-15°C. The mixture was separated by filtration and top-washed with 200mL90% ethanol earlier, and the conductivity of the top-wash liquid was 385us / cm at the end of the top-wash, and then top-washed with 200mL absolute ethanol to obtain 99.7g of vancomycin hydrochloride wet product, wet product Obtain intermediate 72.5g after removing residual ethanol by drying, obtain vancomycin hydrochloride finished product 63.2g after high vacuum drying again, finished product moisture is 3.4%, its bulk density of vancomycin hydroch...

Embodiment 3

[0039] Embodiment 3: the precipitation of vancomycin hydrochloride

[0040] Get 500 mL of the concentrated solution in Example 1, filter through 0.45 μm and 0.2 μm filter membranes and add 15 g of NaHCO while stirring 3 , Vancomycin precipitated from it, forming a slurry, adding HCl aqueous solution to adjust the pH to 3.50, and continuing to stir for 30min to make it evenly mixed, stop stirring and let stand for 48 hours, the process temperature is controlled at 5-6°C. The mixture was separated by filtration and top-washed with 200mL 90% ethanol earlier, and the conductivity of the top-wash solution was 293us / cm at the end of the top-wash, and then top-washed with 200mL absolute ethanol to obtain 92.3g of vancomycin hydrochloride wet product, wet Product obtains intermediate 68.5g after drying to remove residual ethanol, then obtains vancomycin hydrochloride finished product 58.6g after high vacuum drying, and the finished product moisture is 3.1%, and its bulk density of van...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com