Mould temperature control device

A technology for controlling device and mold temperature, which is applied in the field of temperature control device for high-gloss non-marking injection molds. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

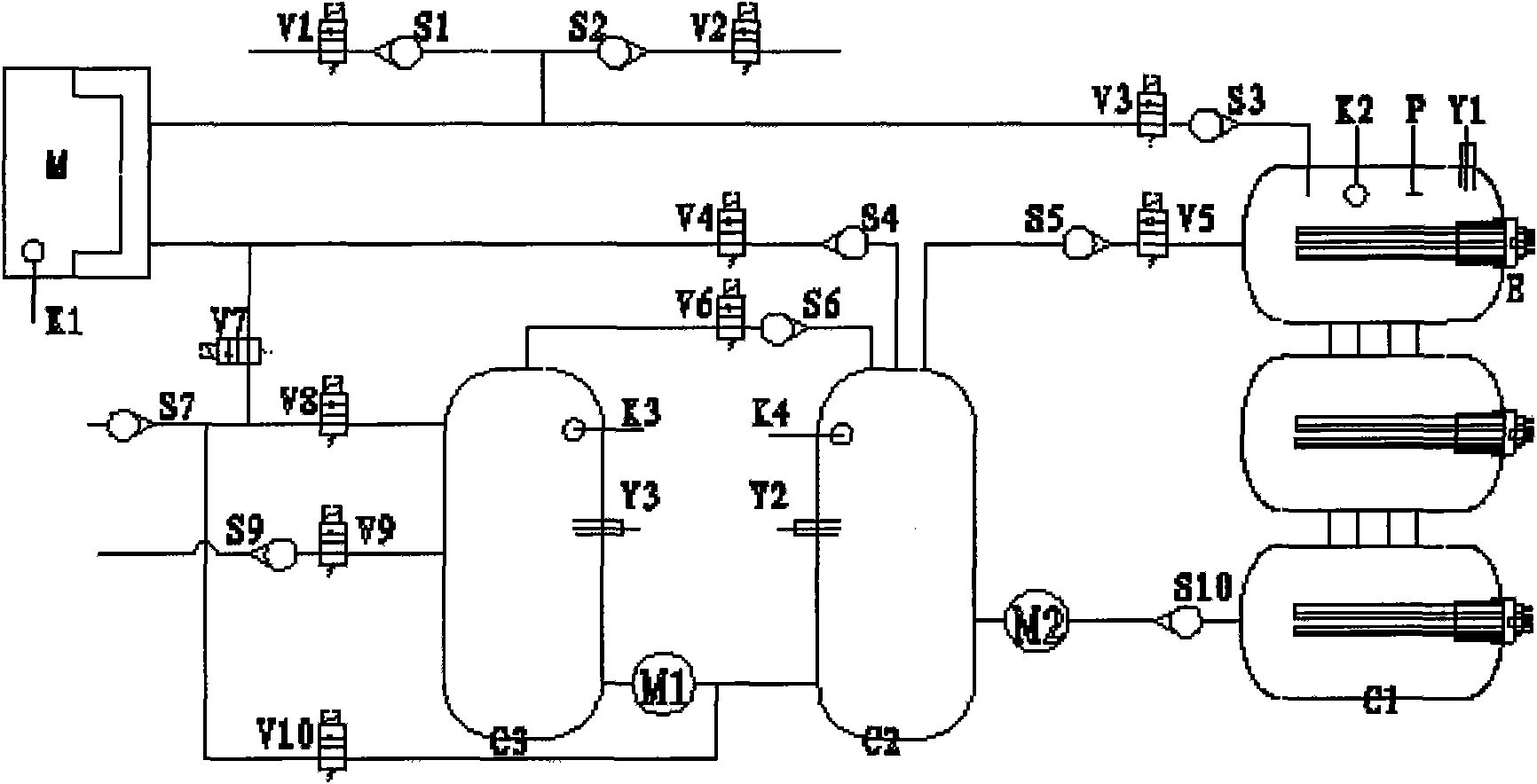

[0020] The core technology of the present invention: use high-temperature and high-pressure hot water as a heating source: use an electric heating tube to heat the water in the heating container, and after reaching a certain temperature, use a hot water pump to transport the hot water to the mold for heating, and heat it to the desired temperature. required temperature stop.

[0021] Recovery of hot water: Use compressed air to blow out the hot water in the mold, and the blown hot water is concentrated in a container specially for collecting hot water, and this container is placed in the pipeline for heating the mold to utilize heat energy.

[0022] When the mold is cooling, pass a certain pressure of cold water into the mold, and stop when it cools to the required temperature; discharge of cold water: blow out the cold water in the mold with compressed air.

[0023] In order to facilitate a further understanding of the present invention, the present invention will now be desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com