Pairing processing method of large-sized and irregular revolving molding surface member

A processing method and irregular technology, applied in the field of paired processing of large-scale rotary surface components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

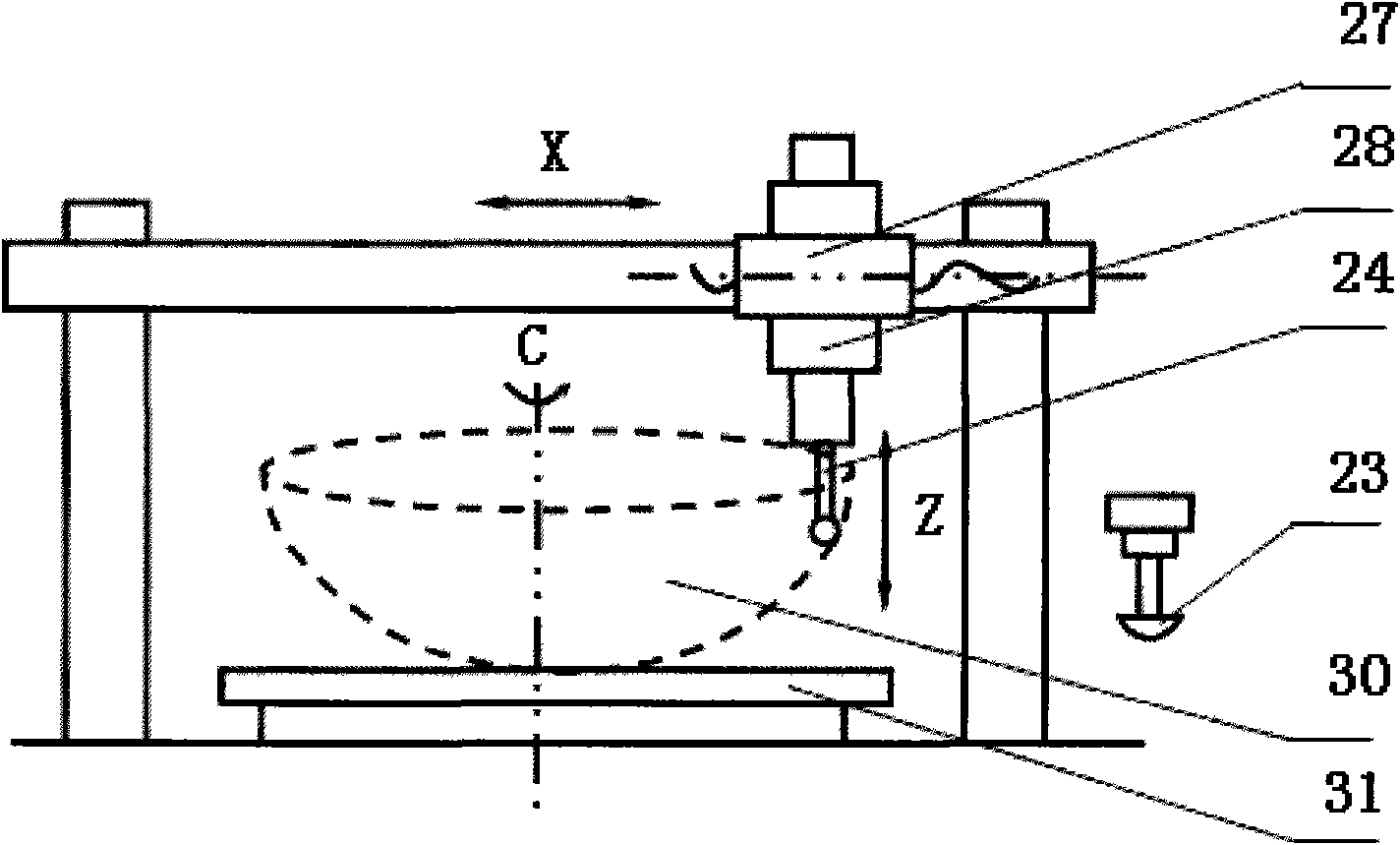

[0065] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-4 As shown, a paired processing method for a large irregular rotary surface member includes scanning and measuring the inner surface of the skin 30, establishing a mathematical model and generating a digital paired processing point set on the surface of the honeycomb sandwich, and processing the upper and lower surfaces of the honeycomb sandwich respectively. , including the following steps:

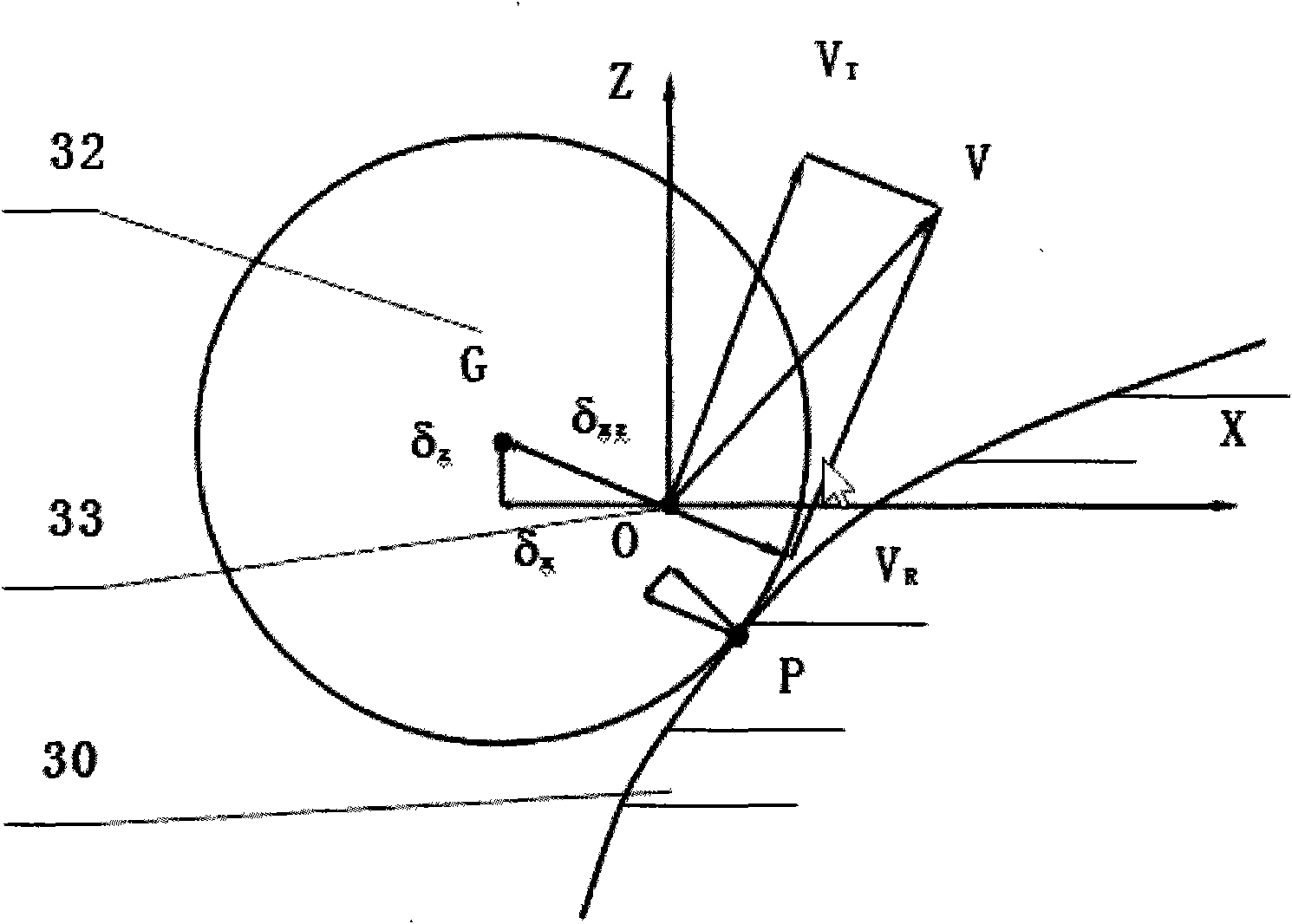

[0066] A. Scanning and measuring the inner surface of the skin 30: using the three-dimensional analog probe 24 to automatically track and measure the actual mating surface of the skin 30 and collect data, and obtain the data point set at the center of the ball end 32 of the three-dimensional analog probe [P] 25;

[0067] B. Establish a mathematical model and generate a digital paired processing point set on the surface of the honeycomb sandwich: perform equidist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com